5. Remove the gear control fork shaft of the 1st

and 2nd gear and, gradually, the gear control fork

shaft of the 3rd and 4th gear, following the proce-

dure described in previous points from 1 to 3.

- CHECK THE REVERSE GEAR CONTROL LEVER MOVE-

MENTS OF THE REVERSE GEAR CONTROL LEVER AND

THE CONTACT WIDTH BETWEEN THE GEAR CONTROL

FORK AND THE RIBBED SLEEVE.

- BEFORE REMOVING THE GEAR CONTROL FORK,

PLACE THE RELEVANT GEARS IN NEUTRAL.

- DURING PIN REMOVAL, MEASURE THE TRACTION

FORCE OF THE SPRING.

Main and transmission shafts

Removal

Removing the input and the secondary shaft

1. Take out the main shaft assembly with the nee-

dle bearing and the synchroniser ring.

N.B.

- MAKE SURE THAT EACH GEAR CAN BE PROPERLY.

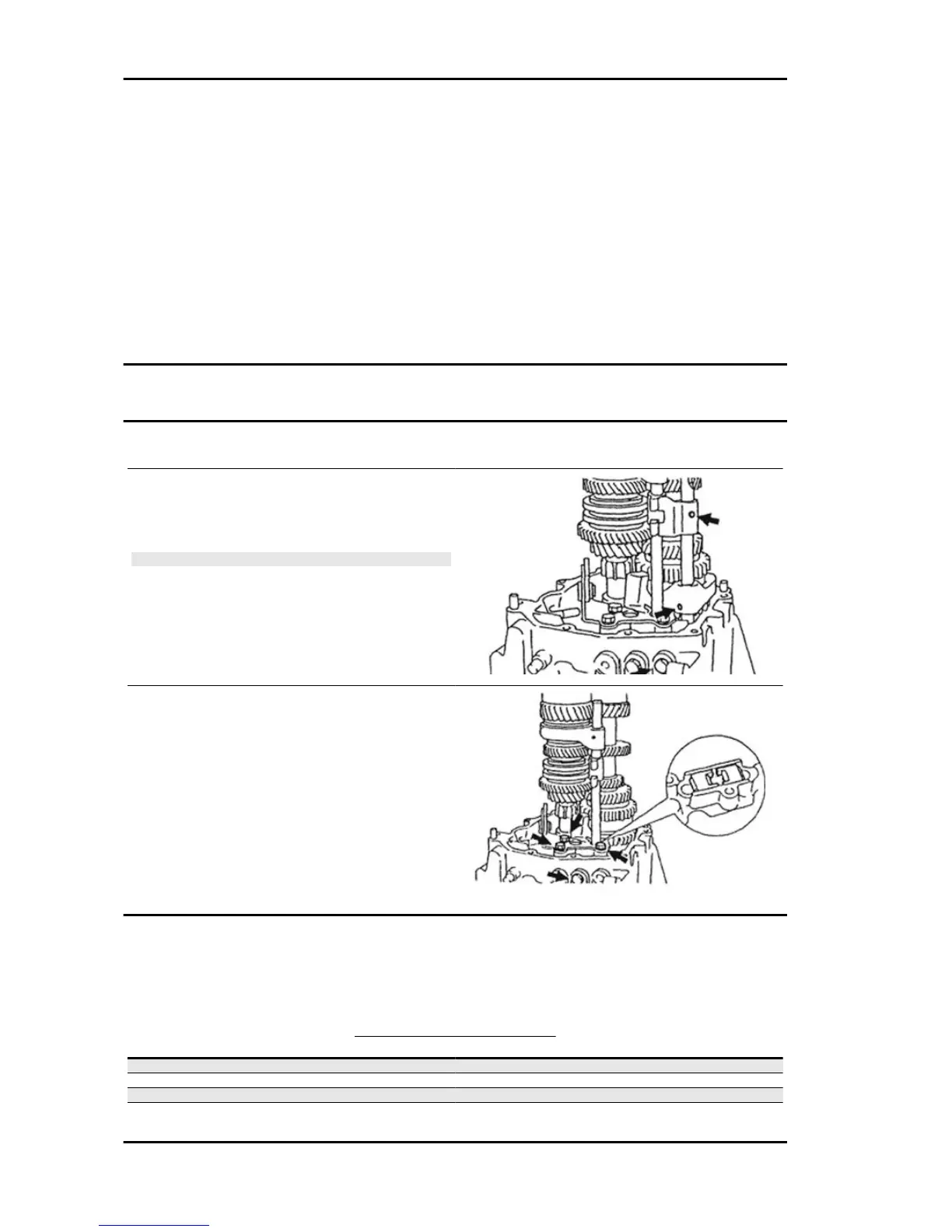

2. Remove the reverse gear control lever, remov-

ing the three bolts.

3. Remove the plate locking the input shaft, by

taking out the three bolts.

4. While the input and the secondary shaft are held

with the hands, slide them off upwards.

Inspection

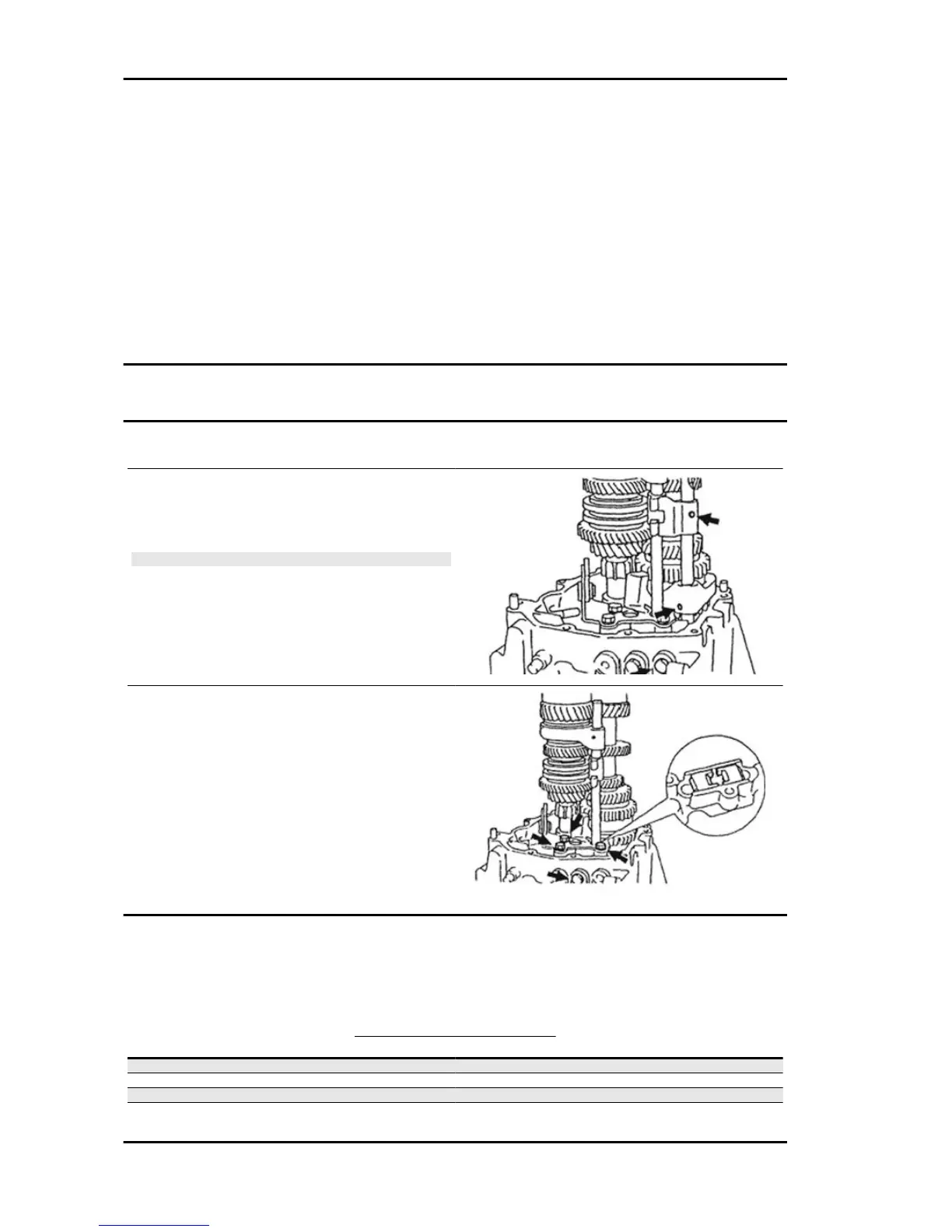

1. Measure the unloaded compression spring length for the gear control fork shafts and for the reverse

gear limit pin

SPRING SPECIFICATIONS

Specification

Desc./Quantity

Unloaded length for gear control fork shafts 40 mm

Fitting load (N) for gear control fork shafts 47.33 N

Fitting height for gear control fork shafts 30 mm

Unloaded length for reverse gear limit pin 24 mm

Gear-box PORTER 1.3 16V

GE - 560

Loading...

Loading...