Procedura ricerca guasti

Checking diagram common options

1. For a correct troubleshooting, refer to the checking procedure detailed for each circuit according to

the failure code diagram or the diagram related to malfunction phenomena.

2. If by troubleshooting of all the components, wires and connectors, except for the electronic control

unit, no malfunction is detected, it is probable that the electronic control unit is not working properly.

Therefore, if no defect is detected after the diagnosis, check the electronic control unit and replace it,

if necessary, also if no problem has been found in it. Check if a malfunction phenomenon has been

detected. If there are no malfunction problems, proceed with checks according to the method of the

malfunction reproduction simulation test.

3. Checking procedures on cable harnesses, electrical and electronic components described in this

chapter can be applied to various systems. Checks must be therefore performed according to these

procedures, as described below.

4. To test the cable harness between the EFI ECU control unit and the DRACO Emission Control Unit,

disconnect the latter from the DRACO and from the EFI ECU and connect the SST on the EFI side.

Then check for open circuits or short circuits with a multimeter, referring to the DRACO pin-out table

(EFI ECU side).

Checking wires and connectors

Wire and connector malfunctions are caused by

interrupted or short-circuited wires.

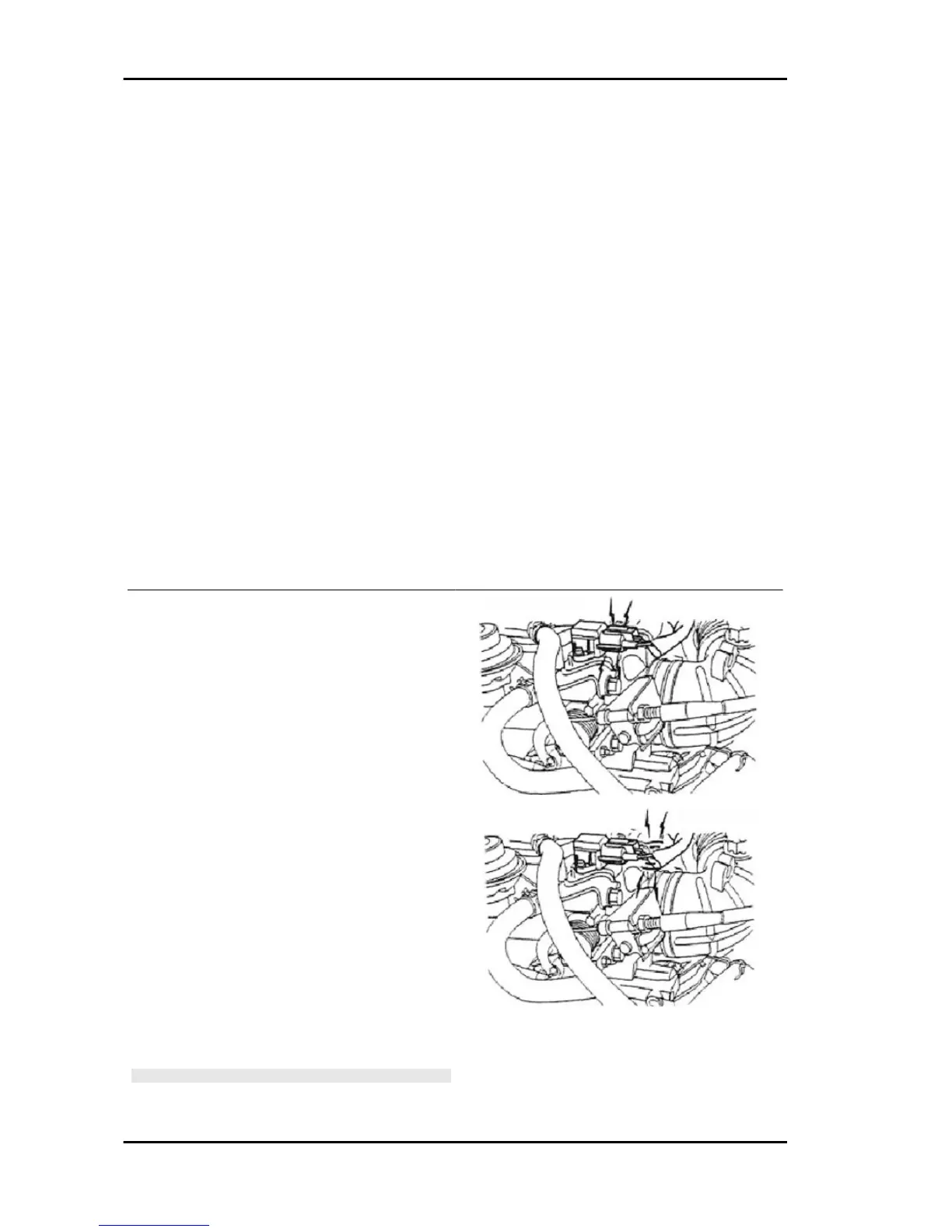

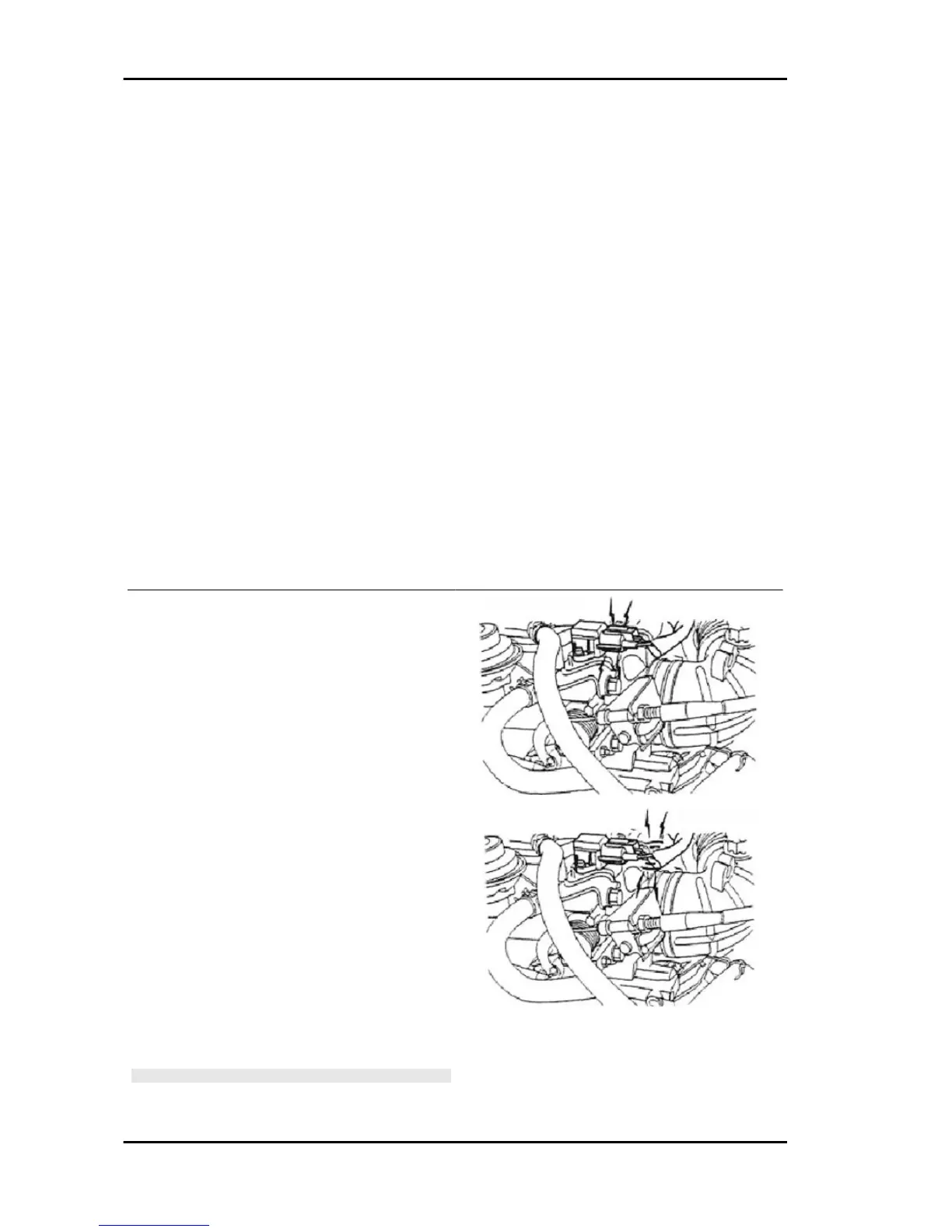

Interrupted wire:

it is caused by detached wires, bad contacts inside

the connector, disconnected connector terminal,

and so on.

- There are bad contacts due to the formation of

oxide on the connector terminal, foreign bodies on

the terminal, or inadequate contact pressure be-

tween the male and female terminals of the con-

nector. Simply disconnect the connector one time,

then connect it again. The contact could be in this

way modified, restoring regular operation. If during

checking no defect is detected in wires and con-

nectors, and if the malfunction stops after finishing

checks, it is probable that the wire or the connector

could be the cause of the problem.

N.B.

- WIRES ARE RARELY CUT AT THE CENTRE. IN MOST OF

THE CASES, THERE IS AN INTERRUPTED WIRE NEARBY

Iniection System PORTER 1.3 16V

IS - 410

Loading...

Loading...