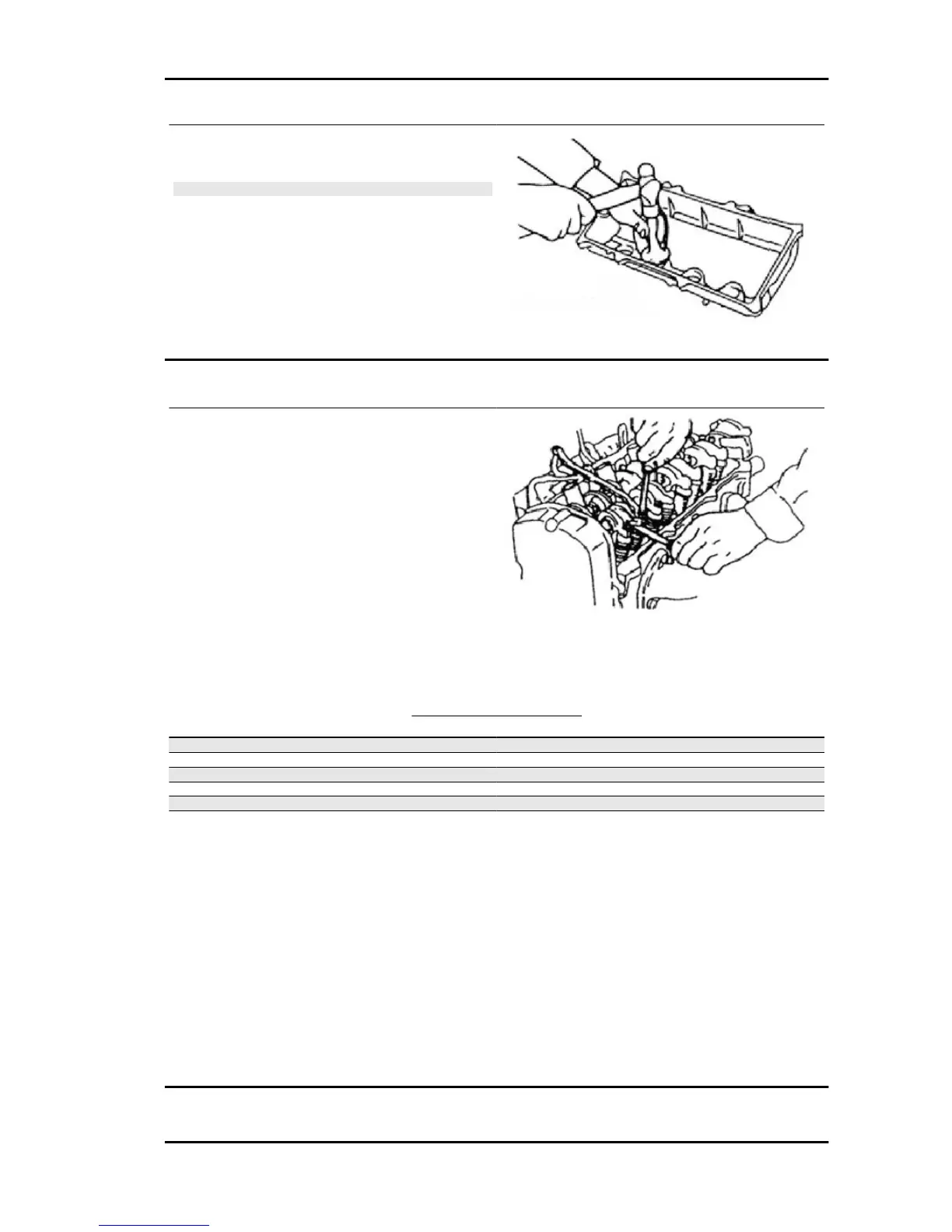

2. Fit a new spark plug sealing ring with the special

tool recommended.

N.B.

- MAKE SURE THAT THE SEALING RING IS ADEQUATELY

POSITIONED.

- USE A SUITABLE WOODEN PIECE TO AVOID DAMAGING

THE CYLINDER HEAD COVER.

- BE CAREFUL NOT TO DAMAGE THE SEALING RING

PROTRUDING PART.

Specific tooling

020274Y Checking tool kit

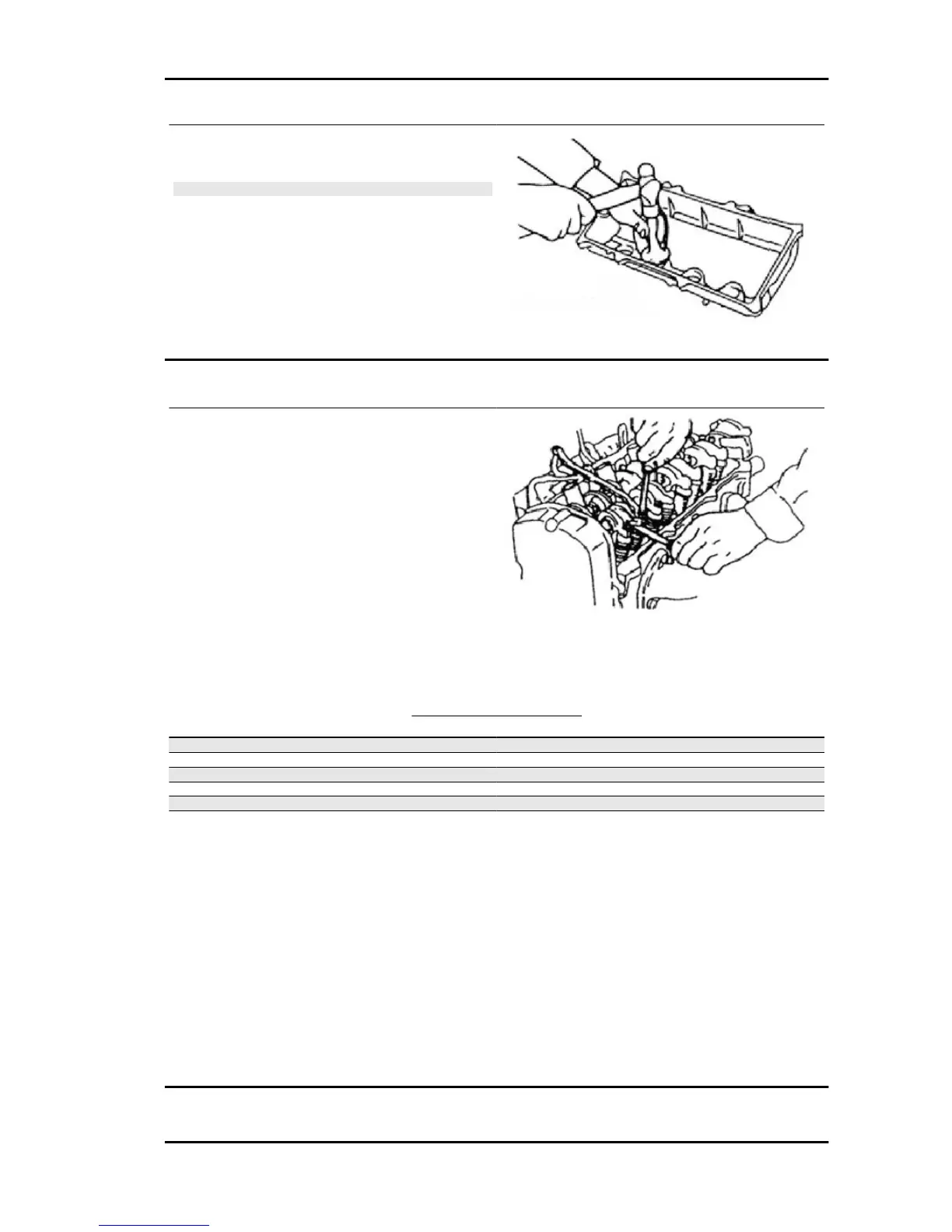

Valve - tappet play

Valve clearance adjustment

Measure and adjust valve clearance when the pis-

ton of cylinders No.1 and No.4 is at the top dead

centre at the end of compression.

AS A RULE, VALVE CLEARANCE IS ADJUSTED WHEN

THE ENGINE IS HOT . "HOT ENGINE" MEANS THAT THE

COOLING WATER TEMPERATURE IS 75 ÷ 85°C AND THAT

THE ENGINE OIL TEMPERATURE IS ABOVE 65°C. NEV-

ERTHELESS, ONCE THE ENGINE IS SERVICED, ADJUST

VALVE CLEARANCES WITH COLD ENGINE AND THEN

ADJUST AGAIN WITH HOT ENGINE AFTER WARMING UP

THE ENGINE.

Locking torques (N*m)

Lock nut 16.7 ÷ 22.5 Nm

VALVE CLEARANCES

Specification

Desc./Quantity

Intake with hot engine 0.25 ± 0.05 mm

Exhaust hot engine 0.33 ± 0.05 mm

Intake with cold engine 0.18 mm

Exhaust with cold engine 0.25 mm

Exhaust with cold engine 0.25 mm

Exhaust with cold engine 0.25 mm

•

With rocking levers for valve of cylinder No.1 free (intake),

adjust the cylinder valves: 1-2

•

The piston of cylinder No.1 is at the top dead centre during compression (exhaust),

adjust the cylinder valves: 1-3

•

With rocking levers for valve of cylinder No.4 free (intake),

adjust the cylinder valves: 3-4

•

The piston of cylinder No.4 is at the top dead centre during compression (exhaust),

Adjust the cylinder valves: 2-4

PORTER 1.3 16V Engine

EN - 261

Loading...

Loading...