Idle speed check and adjustment_

Arrangements to be carried out before the idle

speed adjustment.

- Check and adjust ignition timing.

- Set all the accessory switches to OFF.

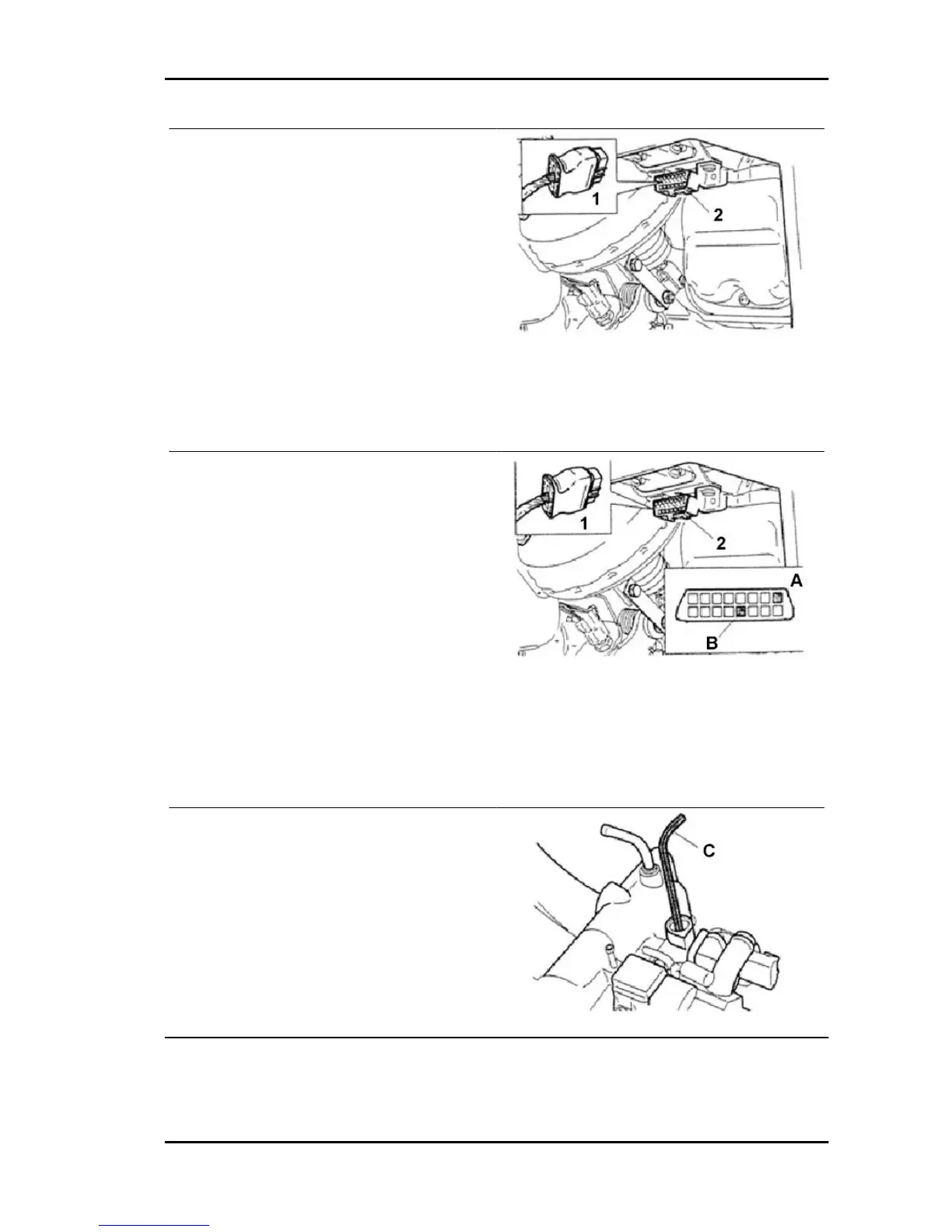

1. Connect the special tool 1 to the diagnostic test-

er connector 2 under the instrument panel.

Specific tooling

020618Y Cable harness for connecting the

OBD Connector and the Diagnostic Tester

2. Prepare the diagnosis instrument DS-21.

3. Warm up the engine. Let the engine run at 2500 rpm for about two minutes.

4. Select the option "Current data indication -

Current data monitoring " from the option list.

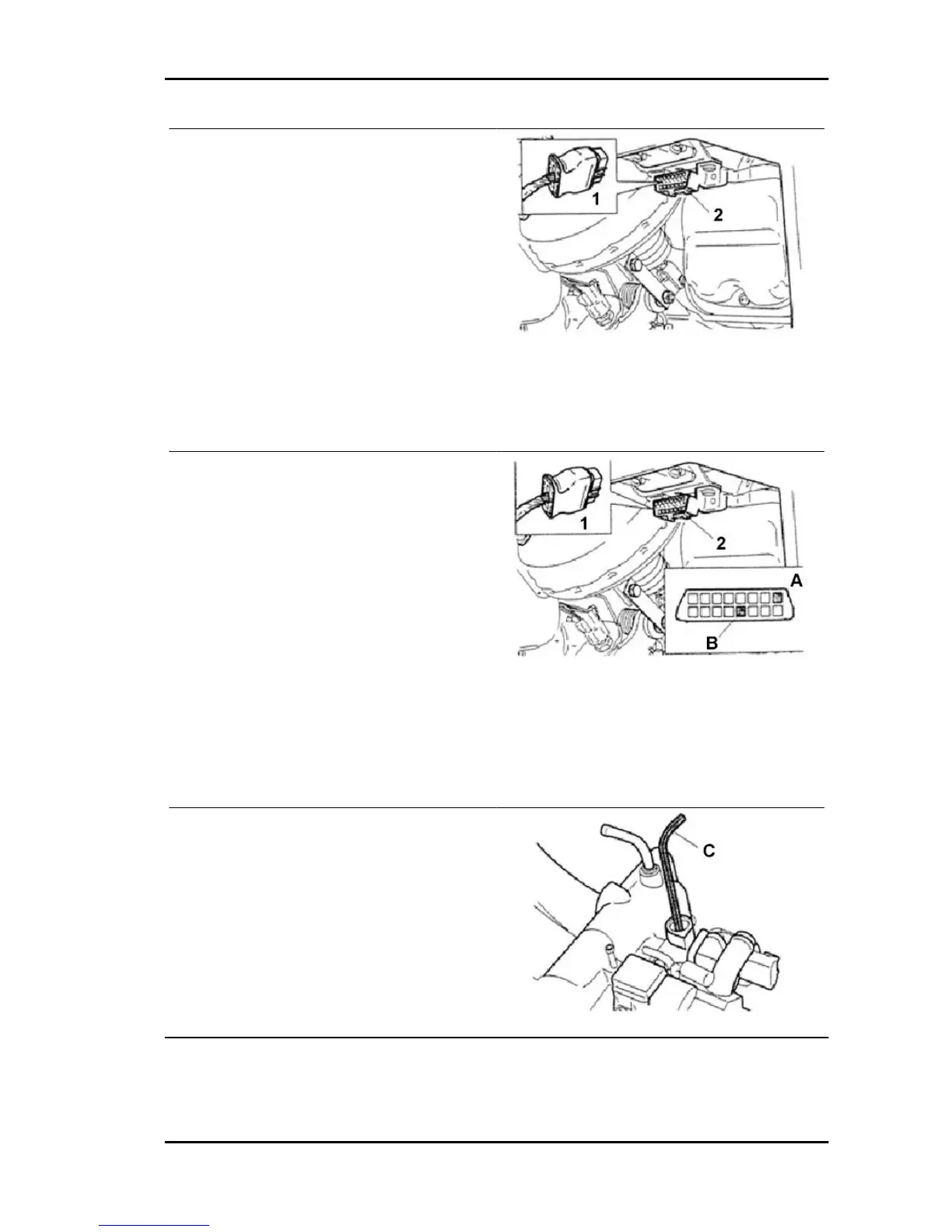

WHEN THE DIAGNOSIS INSTRUMENT DS-21 IS NOT

USED, CONNECT A RPM INDICATOR TO THE REV. TER-

MINAL USING THE SPECIAL TOOL (SST).

Specific tooling

09991-87402-000 Rpm indicator pulse pickup

wire (Engine speed measurement)

KEY:

1. Special tool

2.Diagnostic tester connector

•

A REV CONNECTOR

•

B Ground

5. Measure the idle speed. M/T vehicles: 900 ± 50

rpm

If the number of revolutions at idle speed does not

correspond to the specified value, adjust by means

of the idle speed set screw located on the throttle

body using a key C of 4 mm.

TO REDUCE THE NUMBER OF REVOLUTIONS, TURN THE

IDLE SPEED SET SCREW CLOCKWISE. TO INCREASE,

TURN THE IDLE SPEED SET SCREW ANTICLOCKWISE.

Clutch

Clutch

PORTER 1.3 16V Engine

EN - 339

Loading...

Loading...