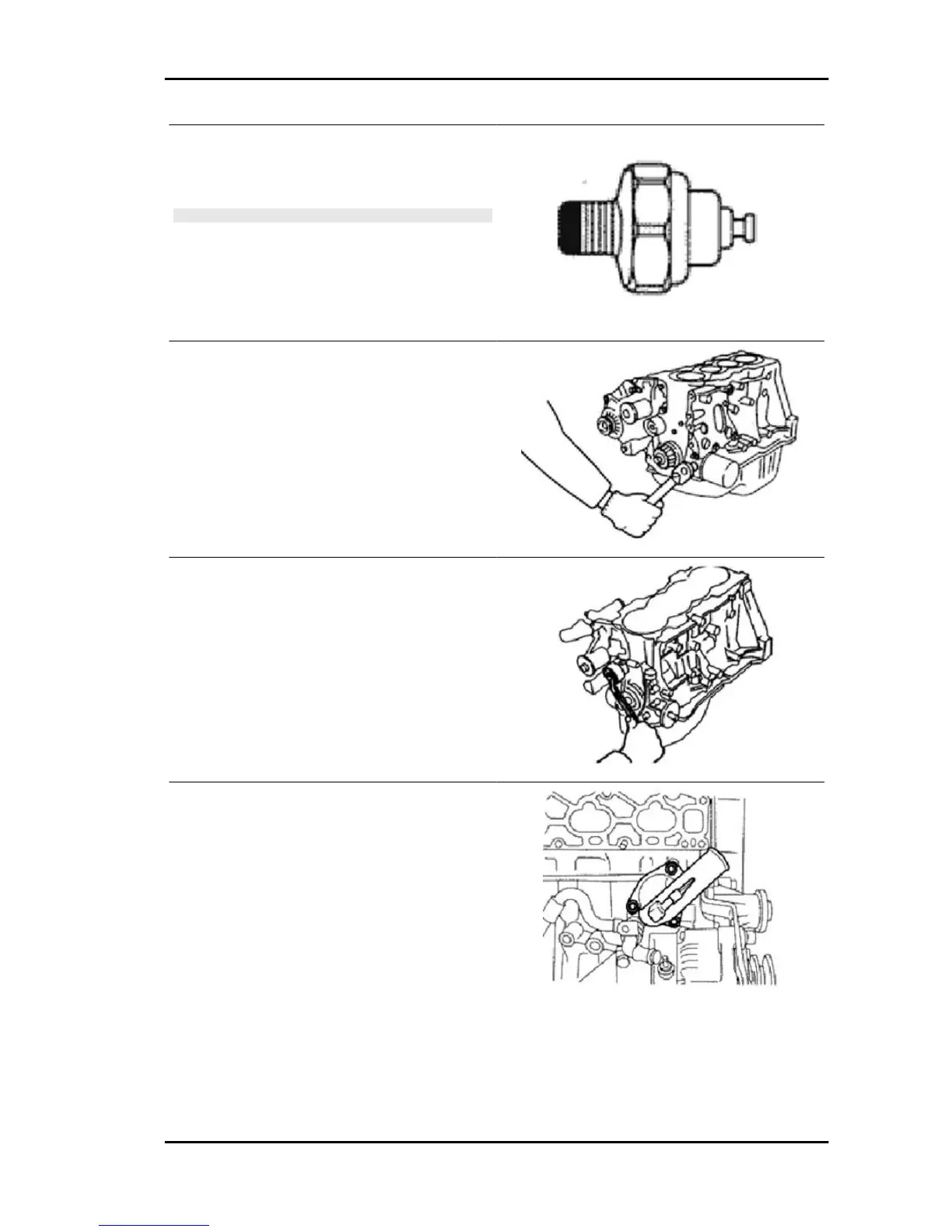

pressure switch fitting

1. Clean the threaded part of the pressure switch.

Wrap a sealing tape around the threaded part.

N.B.

- THE NEW PRESSURE SWITCHES ARE COATED WITH

SEALANT. THEREFORE, WHEN THE PRESSURE SWITCH

IS REPLACED WITH A NEW ONE, FIRST, REMOVE THE

COATING COMPLETELY SINCE THE PRODUCT LOOSES

ITS CHARACTERISTICS WITH TIME. ALSO CLEAN THE

THREADED HOLES WHERE THE SWITCH IS FITTED.

2. Tighten the oil pressure switch to the specified

torque value, using a box-spanner.

Locking torques (N*m)

Oil pump - Oil pressure switch 12÷20

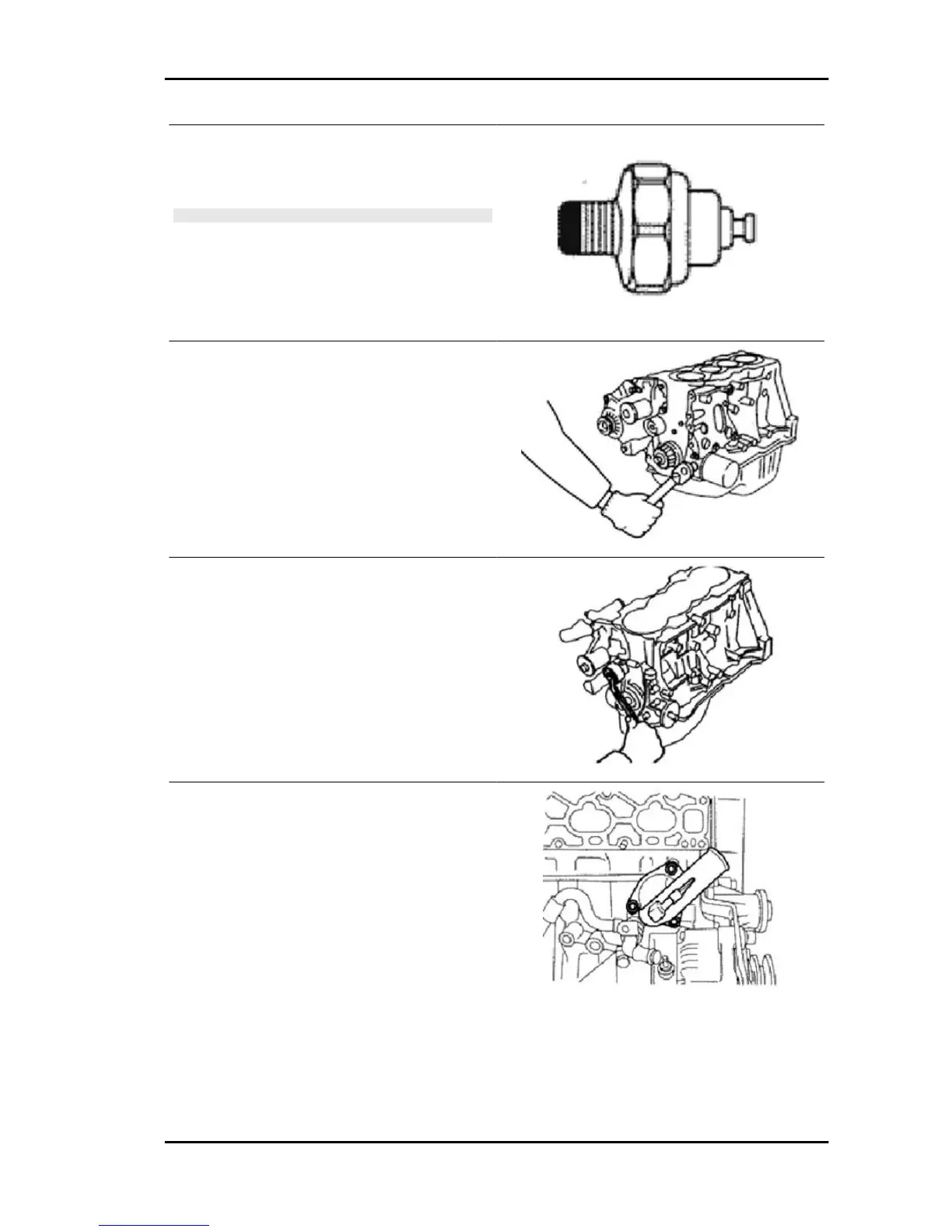

Spring connection to the timing belt tensioner

Connect the spring to the timing belt tensioner. At-

tach the spring ring on the pin. Fit the belt tensioner

and fit the screw.

Push the tensioner towards the alternator to the

end of the travel position. Temporarily tighten the

tensioner.

Water filler fitting

Fit the water filler.

Locking torques (N*m)

Cylinders lock for water inlet 5.9 ÷ 8.8 Nm

PORTER 1.3 16V Engine

EN - 323

Loading...

Loading...