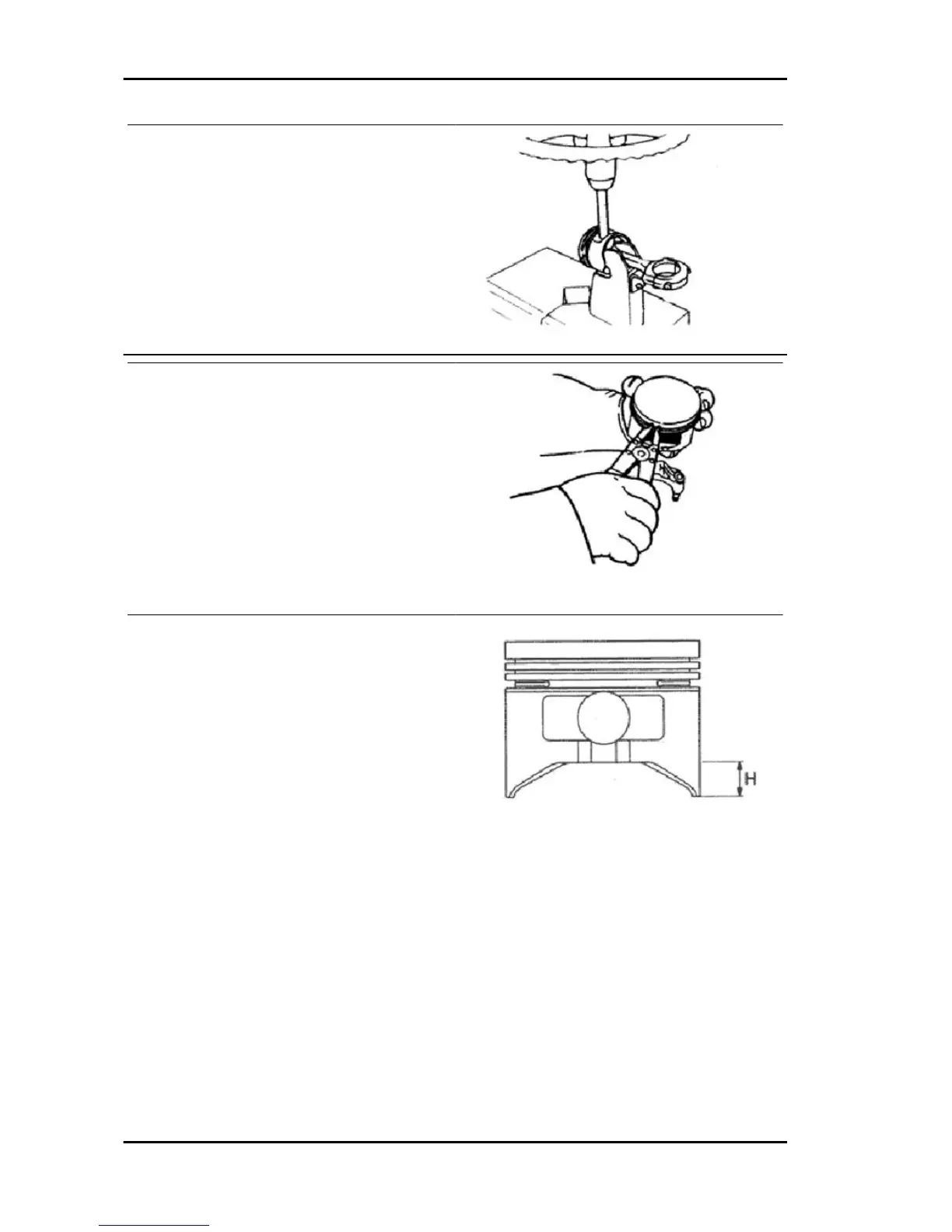

2. Fit the special tool in pin hole.

Take out the pin with a hydraulic press.

- DISASSEMBLE THE SPECIAL TOOL AND USE ONLY THE

CYLINDRICAL PART.

Piston inspection

1. Piston cleaning

•

Remove the piston rings.

•

Remove the carbon deposits from the

upper part of the pistons, with a scra-

per.

•

Clean the slots for the piston rings with

a portion of the sealing ring.

- BE CAREFUL NOT TO SCORE THE SLOTS FOR THE PIS-

TON RINGS.

2. Piston check

Visually check the piston to detect any cracks,

damage or seizures. Replace the piston, if neces-

sary.

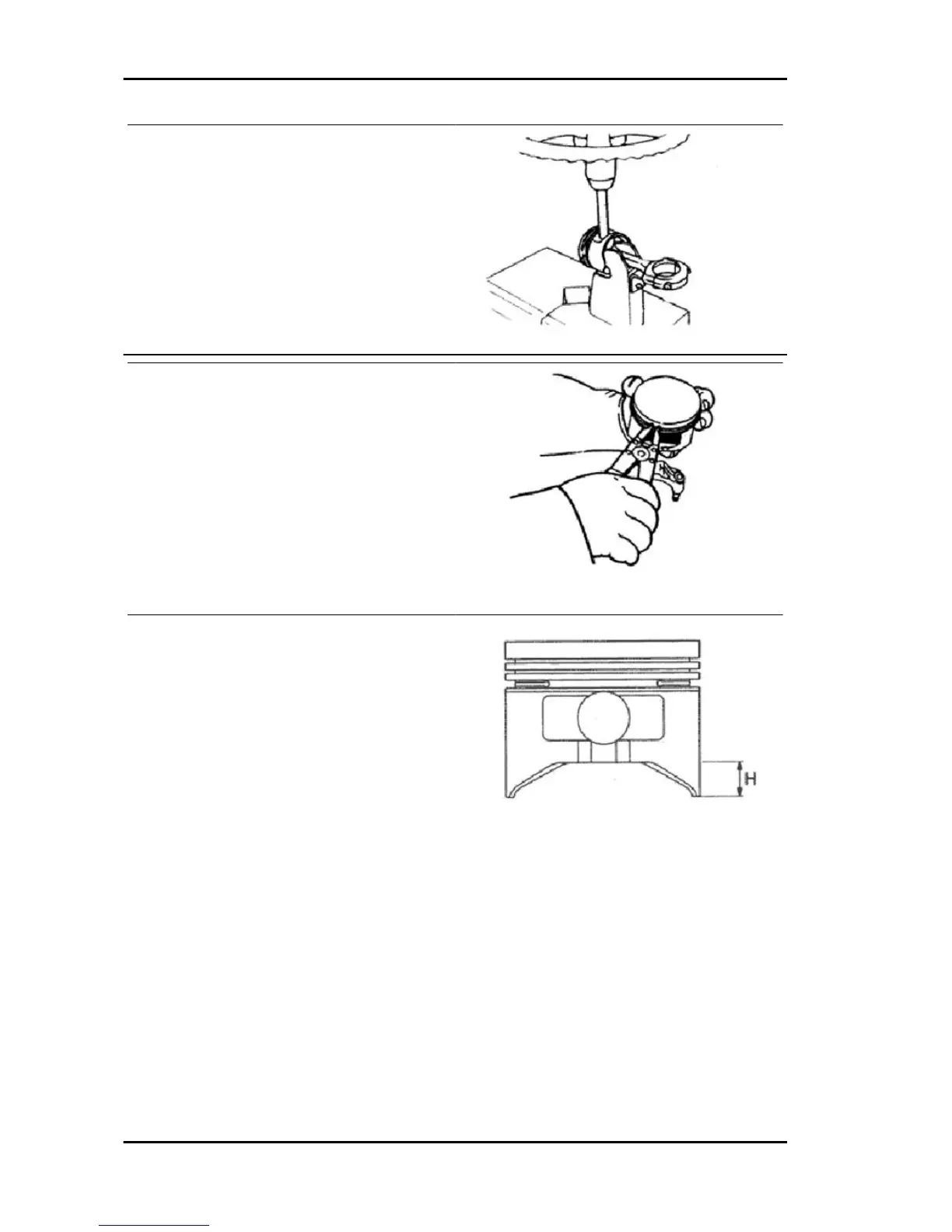

3. Piston diameter measurement

•

Measure the outside diameter at the

point specified, and in a perpendicular

position to the pin.

If the piston ring opening exceeds the allowed limit,

the whole kit must be replaced.

Characteristic

Point H of measurement:

15 mm

•

Calculate the cylinder piston coupling.

Deduct the piston diameter from the cylinder diameter.

Make sure that clearance between the piston and the cylinder is below 0.045 mm.

If the cylinder piston clearance exceeds the lower limit, carry out the reaming and smoothing operations

of the cylinders, so that the cylinder diameter couples with the oversized piston.

Engine PORTER 1.3 16V

EN - 300

Loading...

Loading...