Driving belt test

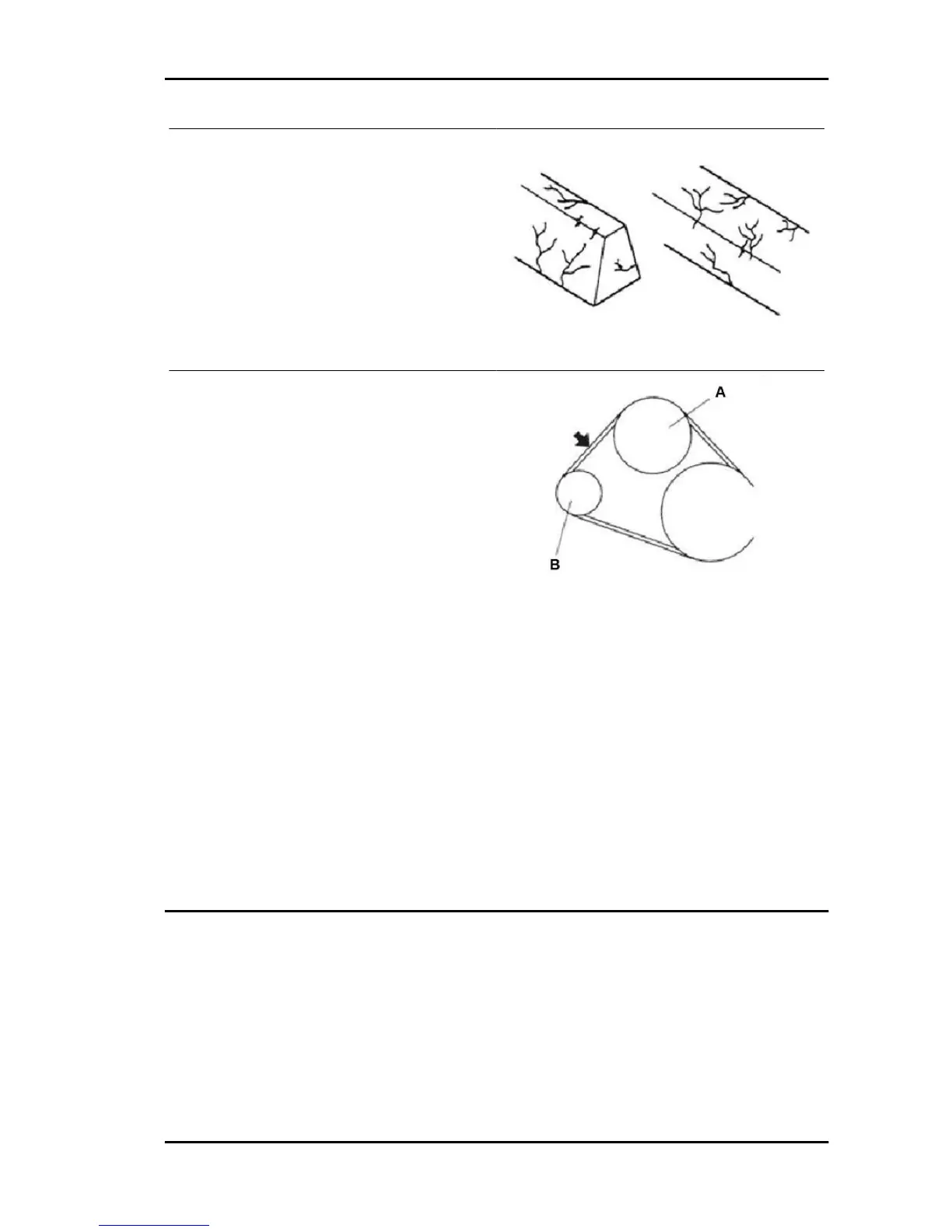

1. Visual inspection of the driving belt.

Visually check the belt for any traces of separation

of the upper or lower part of the belt from the ad-

hesive rubber, belt core separations from the

sides, belt core ravelling, adhesive rubber weft

ravelling, cracks or separations of ribs, tearing or

cracking in the belt internal ribs. Replace the driv-

ing belt, if necessary.

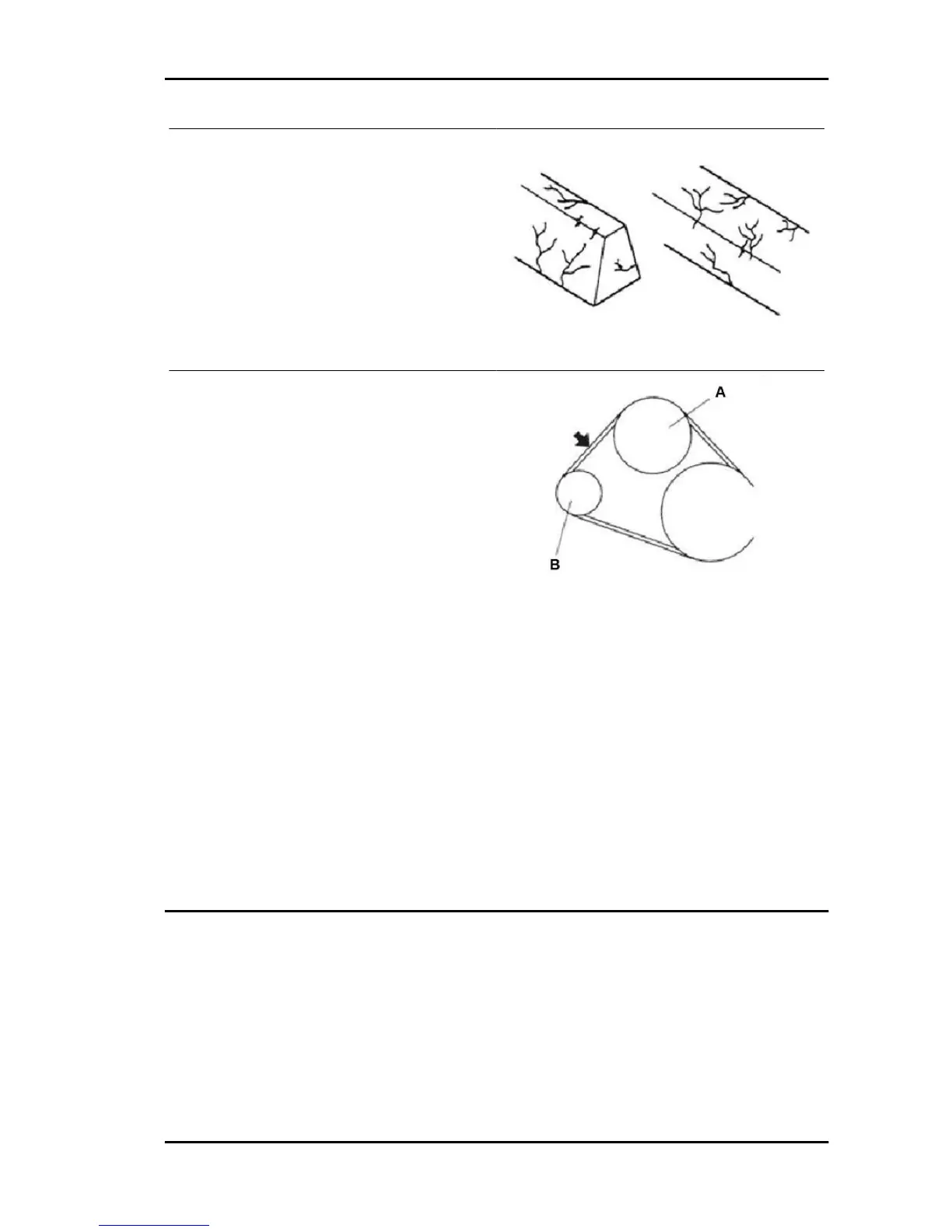

2. Driving belt tension test. Measure the driving

belt deflection (bending) when a 98 N (10 Kgf)

force is applied at the middle point of the belt, be-

tween the alternator pulley and the water pump

pulley.

Characteristic

Rated deflection of the New Belt (with a 10 kg

force applied at the indicated point):

3.5 - 5.5 mm

Rated deflection of the Used Belt (with a 10 kg

force applied at the indicated point):

4.5 - 6.5 mm

KEY:

A = Water pump pulley

B = Alternator pulley

Adjust driving belt tension, if necessary.

•

A "NEW BELT" IS A BELT THAT HAS BEEN USED FOR LESS THAN FIVE MINUTES ON

A RUNNING ENGINE.

•

A "USED BELT" IS A BELT THAT HAS BEEN USED FOR MORE THAN FIVE MINUTES

ON A RUNNING ENGINE.

•

AFTER FITTING A NEW BELT, LET THE ENGINE RUN FOR AT LEAST FIVE MINUTES

AND THEN CHECK TENSION AGAIN.

PORTER 1.3 16V Engine

EN - 233

Loading...

Loading...