3. Grind the cylinder after the reaming.

•

Ream the cylinder, leaving a reaming tolerance of 0.02 mm.

•

Grind the cylinder.

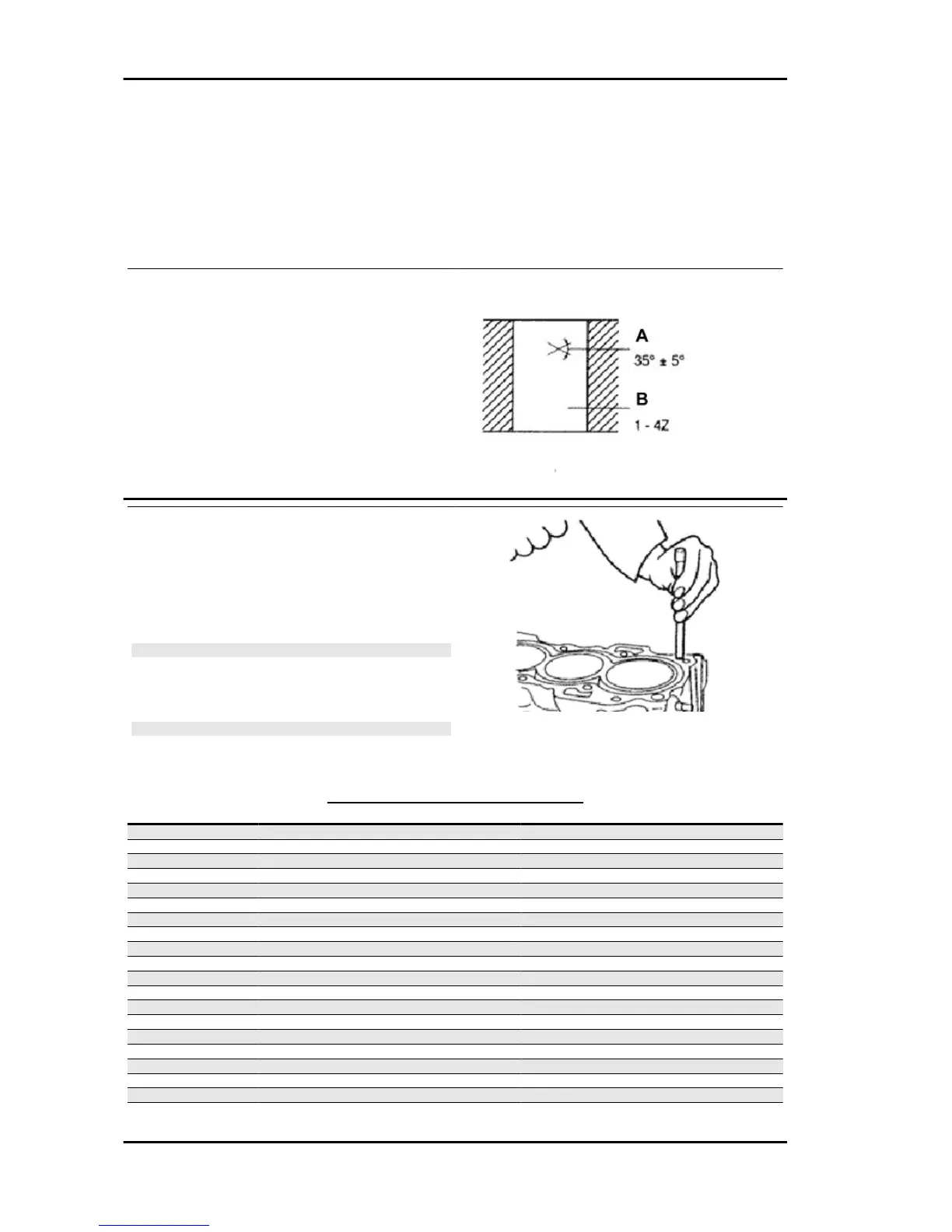

Grinding angle: 35° ± 5°

Degree of surface machining: 1 - 4Z

A = Grinding angle

B = Surface machining

Cylinder block replacement

1. Wash the cylinder block using solvent.

2. Insert the shutter on the oil delivery up to a 3.0

± 1.0 mm depth, measured from the upper surface

of the cylinder.

N.B.

- THE CYLINDER BLOCK IS PROVIDED TOGETHER WITH

THE PISTONS, AS A SINGLE KIT. THEREFORE, BE CARE-

FUL THAT EACH PISTON IS FITTED IN THE RELEVANT

CYLINDER.

N.B.

- TO INSERT THE PARALYSER, USE A 10 MM OUTSIDE

DIAMETER BUFFER.

CONNECTING ROD HEAD TYPES

Name

Description Dimensions Initials Quantity

Category 5 50.000 - 49.995 1

Category 5 49.994 - 49.989 2

Category 5 49.998 - 49.983 3

Category 5 49.982 - 49.976 4

Category 5 49.975 or less -

Category 6 50.000 - 49.995 2

Category 6 49.994 - 49.989 3

Category 6 49.998 - 49.983 4

Category 6 49.982 - 49.976 5

Category 6 49.975 or less -

Category 7 50.000 - 49.995 3

Category 7 49.994 - 49.989 4

Category 7 49.998 - 49.983 5

Category 7 49.982 - 49.976 6

Category 7 49.975 or less -

Category 8 50.000 - 49.995 4

Category 8 49.994 - 49.989 5

Category 8 49.998 - 49.983 6

Category 8 49.982 - 49.976 7

Category 8 49.975 or less -

Engine PORTER 1.3 16V

EN - 312

Loading...

Loading...