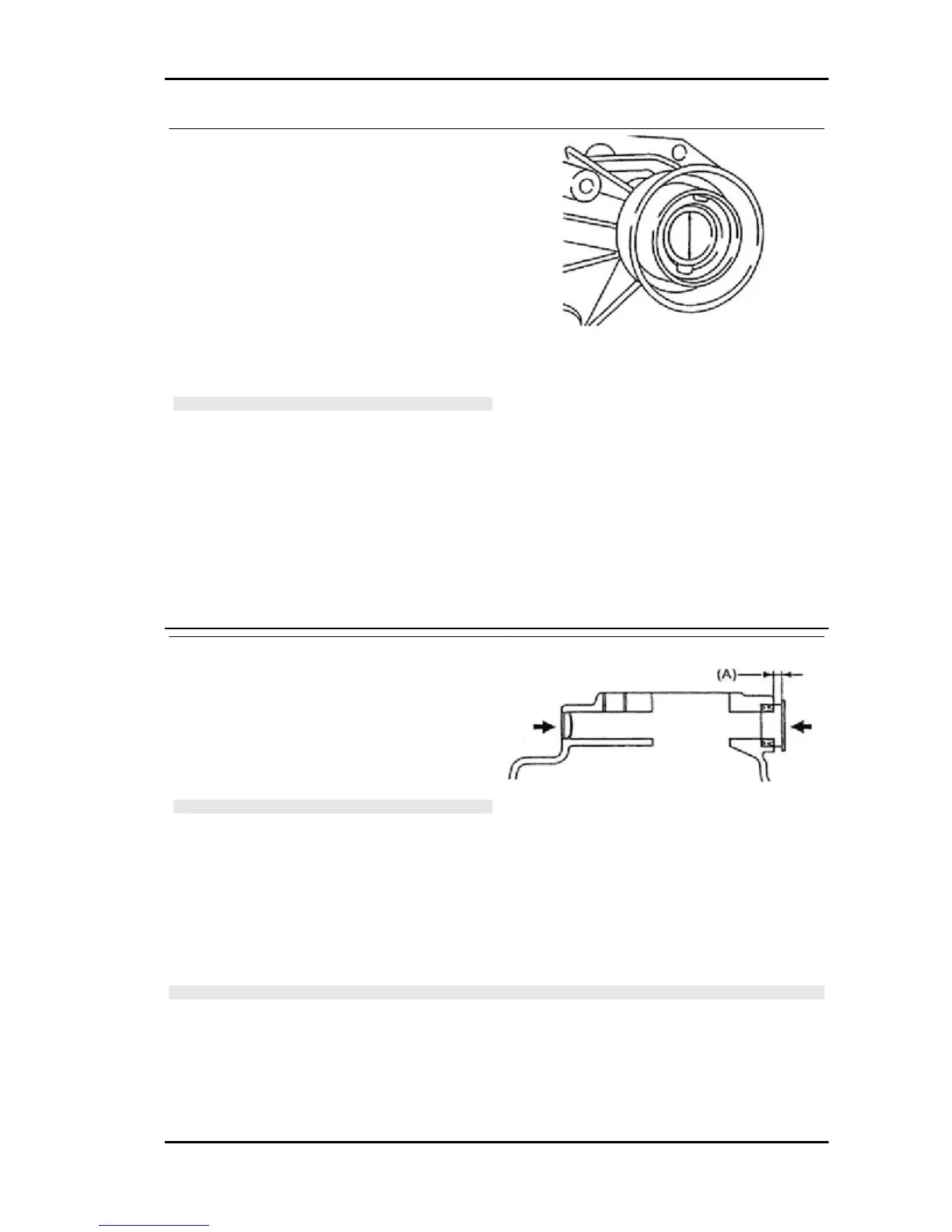

Bimetallic bushing

1. Remove the oil seal.

2. Visually inspect the internal surface of the stam-

ped bimetallic bushing, and check for possible

discolouration or scoring.

3. Measure the inside diameter of the stamped bi-

metallic bushing.

4. Apply lithium grease onto the edge of the new

gasket.

5. Fit the new gasket.

N.B.

- THE HOLE DIAMETER SHALL MATCH THE SPECIFIED

VALUE. AN EXCESSIVELY LARGE DIAMETER CAUSES

OIL LEAKAGE. THE BIMETALLIC BUSHING SHALL BE RE-

PLACED TOGETHER WITH THE GEARBOX COVER.

Specific tooling

020200Y Extractor

Characteristic

Specified value:

30.0 + 0.021 mm + 0 mm

Replacement of gearshift lever and gear com-

ponents

Removal

1. Remove the sleeve of the selection lever.

2. Remove the sealing cap (if necessary).

3. Remove the T oil seal.

N.B.

- DO NOT REUSE THE SEALING CAP AND THE OIL SEAL

PREVIOUSLY REMOVED .

Installation

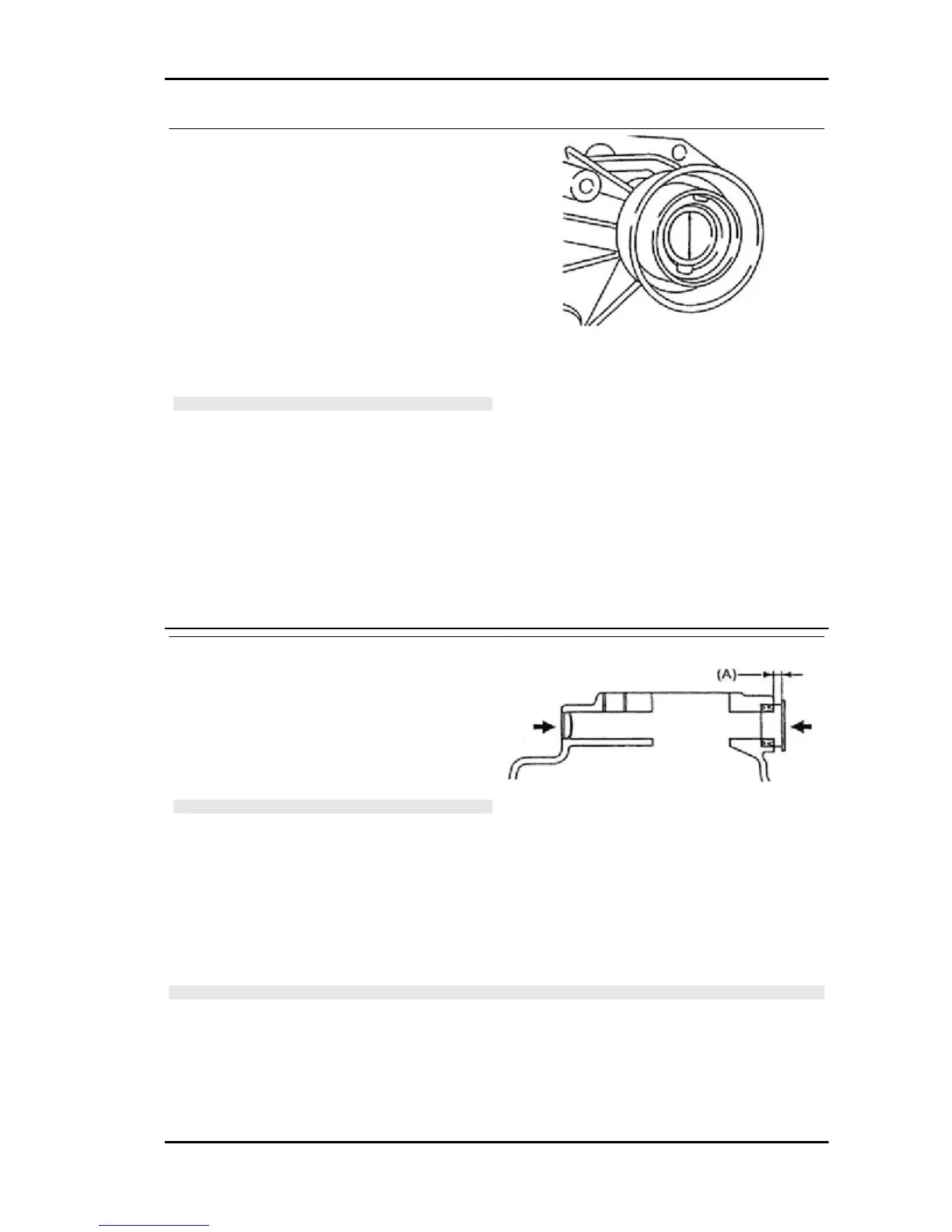

1. Fit a new sealing cap, as shown in the figure on the right.

2. Fit a new T oil seal, as shown in the figure on the right.

3. Make sure that the protruding part A of the T oil seal complies with the specified value.

4. Check there is electric continuity between the switch and the reverse bulb.

N.B.

- IF THE PROTRUDING PART EXCEEDS THE VALUE SPECIFIED ABOVE (OR 5.3 MM), IT CAN

CAUSE OIL LEAKAGE.

Characteristic

Specified value:

5 ± 0.3 mm

PORTER 1.3 16V Gear-box

GE - 563

Loading...

Loading...