Checks

Checking each part

- Wash the parts to be removed using solvent for

cleaning.

- Check for possible damage to the pump body.

- Check for possible damage to the rotor

- Check for possible damage to the oil pump valve.

- Check for possible damage to the spring retaining

cap.

- Check for possible damage to the compression

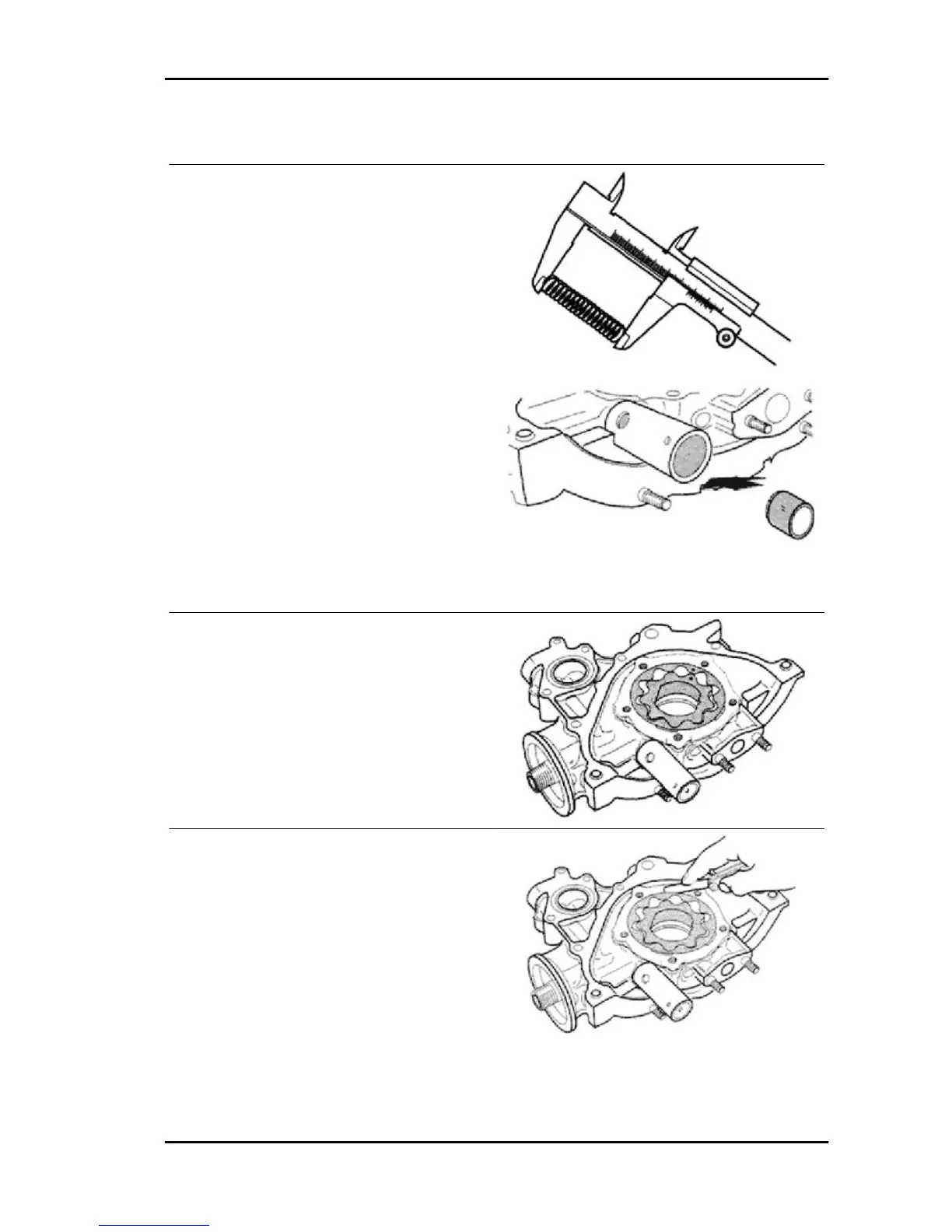

spring and measure the relevant unloaded length.

Unloaded length prescribed value: 57 mm

- Apply engine oil onto the pump safety valve. In-

sert the valve in the pump and check for correct

operation.

- REPLACE EACH SINGLE DAMAGED PART. - REPLACE

THE COMPRESSION SPRING IF DAMAGED OR IN CASE

ITS UNLOADED LENGTH IS SHORTER THAN THE PRE-

SCRIBED VALUE. - REPLACE THE PUMP IF THE VALVE IS

NOT WORKING PROPERLY.

Measuring pump housing clearance, upper

part and side clearance.

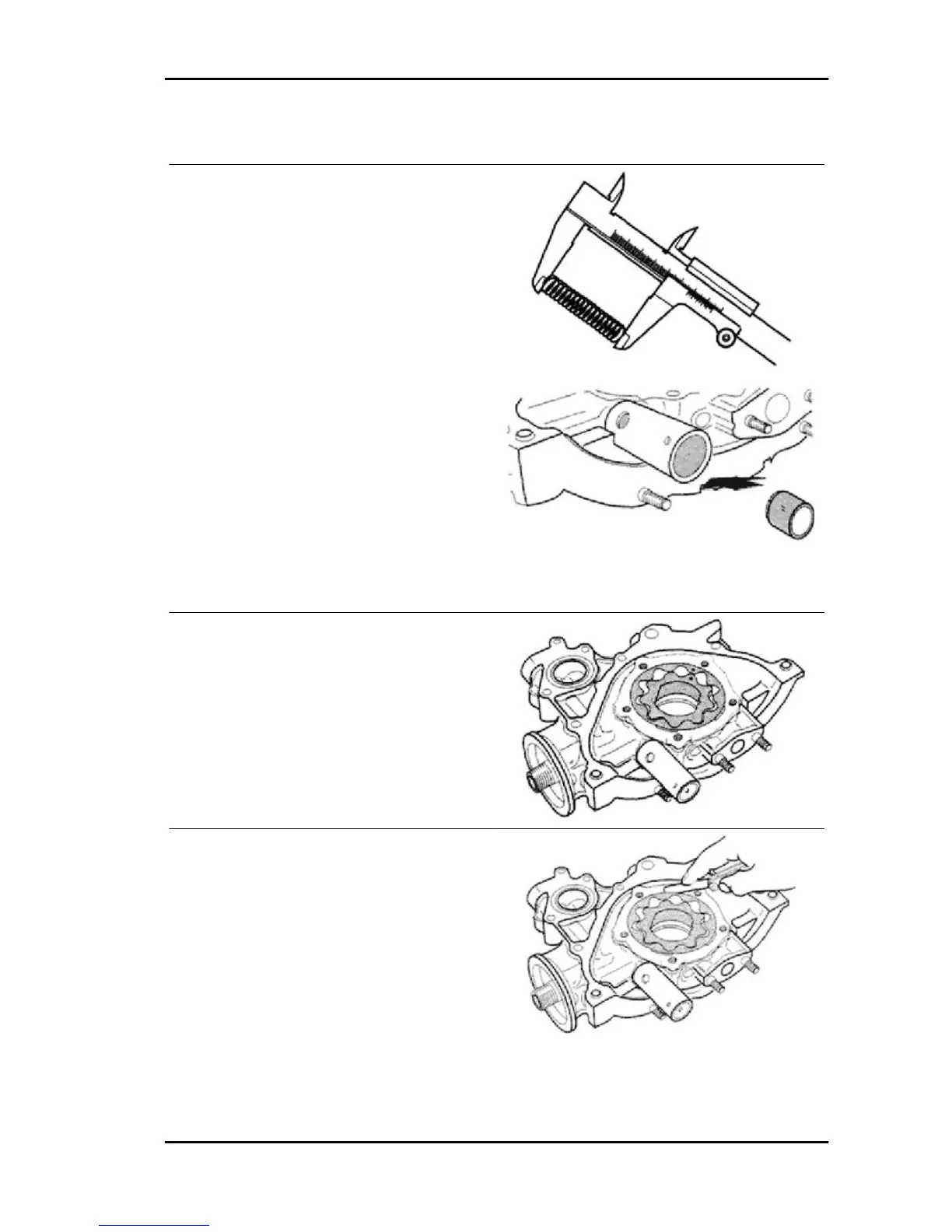

1. Apply a thin layer of engine oil onto the surface

joining the oil pump assembly rotors and on the

rotor series. Fit the rotor series on the oil pump

assembly so that the drilled mark is visible from the

outside.

2. Rotor clearance - pump housing measurement

With a thickness gauge, measure clearance be-

tween the external rotor and the pump housing.

REPLACE THE OIL PUMP IF CLEARANCE EXCEEDS THE

PRESCRIBED VALUE.

Characteristic

Clearance:

0.20 - 0.28 mm

PORTER 1.3 16V Engine

EN - 357

Loading...

Loading...