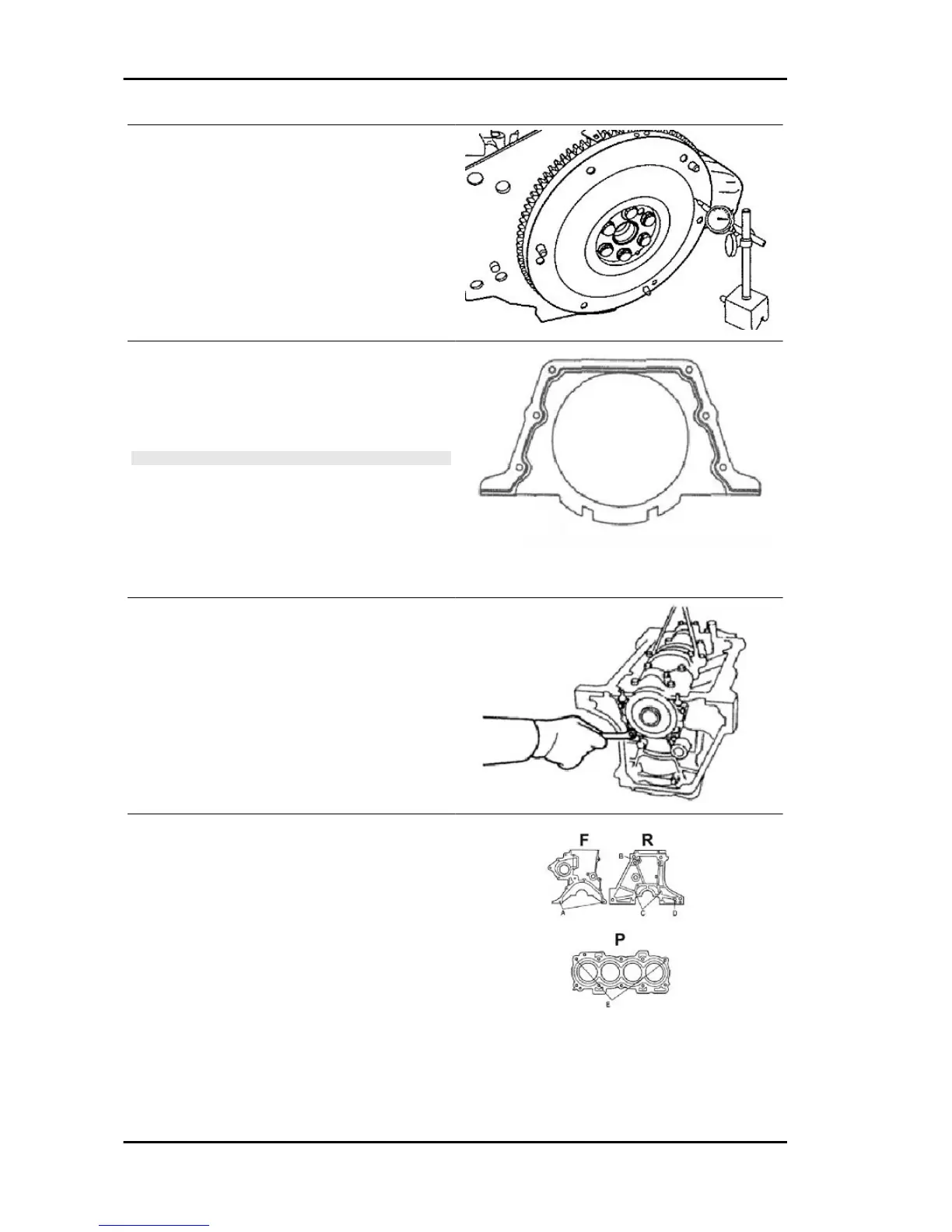

5. Measure the flywheel eccentricity using the dial

gauge.

- REPLACE THE FLYWHEEL IF ECCENTRICITY EXCEEDS

THE LIMIT ALLOWED.

Characteristic

Maximum limit allowed

0.1 mm

Fitting the flange supporting the flywheel side

sealing ring

1. Apply sealant onto the coupling surface with the

cylinder block, as shown in the figure.

CAUTION

- APPLY THE RIGHT SEALANT QUANTITY IN ORDER TO

AVOID THE FORMATION OF EXCESSIVE RESIDUES IN-

SIDE THE ENGINE.

Recommended products

Three Bond 1207C SEALANT

-

2. Apply engine oil onto the sealing ring internal

surface.

Fit the flange to the cylinder block. Tighten to the

specified torque values.

Locking torques (N*m)

Cylinder block - Rear oil seal ring 6÷9

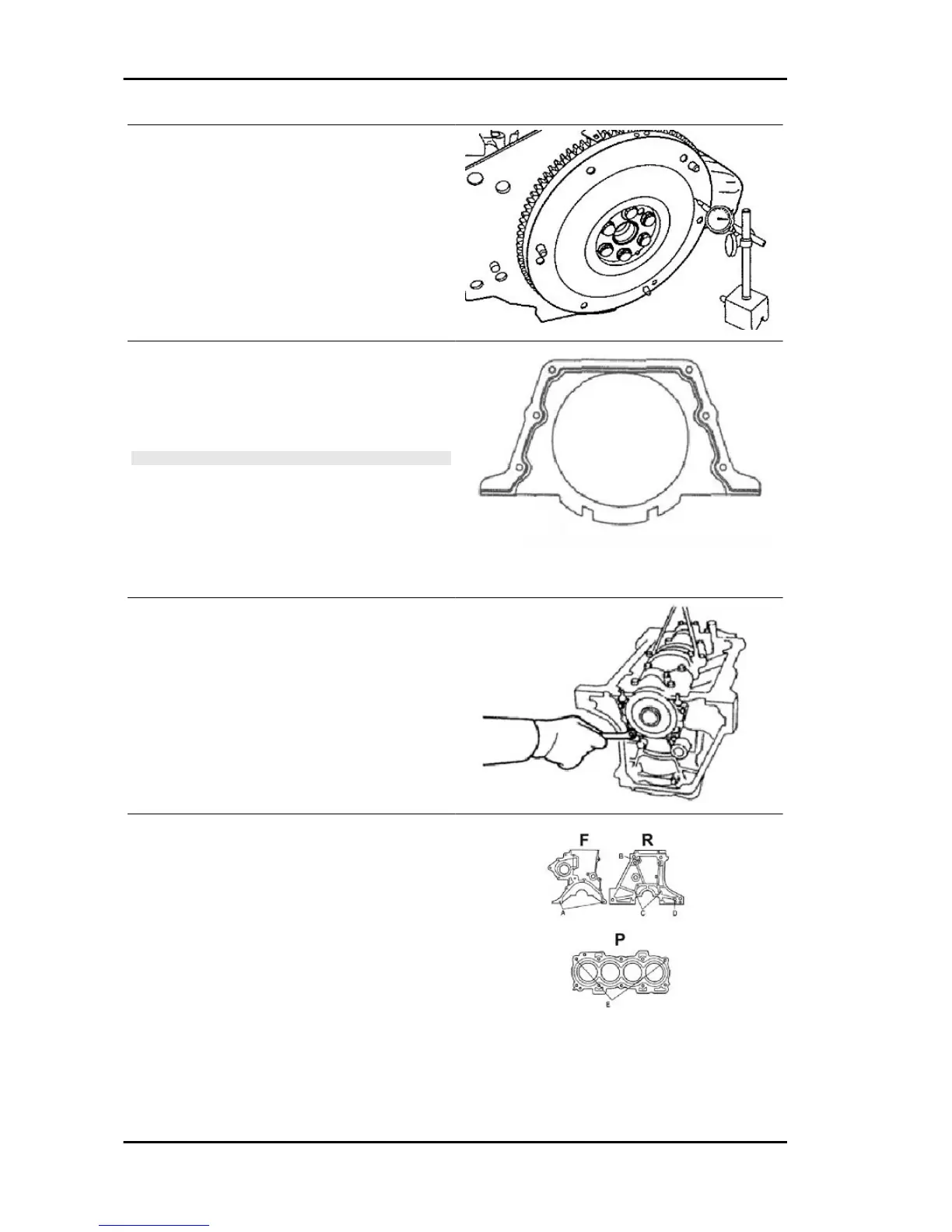

Cylinder block fitting

1. Make sure that pins are fitted at the front, rear

and upper positions of the cylinder block, accord-

ing to the indications indicated in the figure.

Make sure that the protrusion of each single pin,

complies with the value specified below.

Specific protrusion value

A: 4 ± 0.5 mm

B: 8 ± 1.0 mm

C. 7 ± 1.0 mm

D: 3 ± 1.0 mm

Engine PORTER 1.3 16V

EN - 326

Loading...

Loading...