Cylinders

Cylinder block test

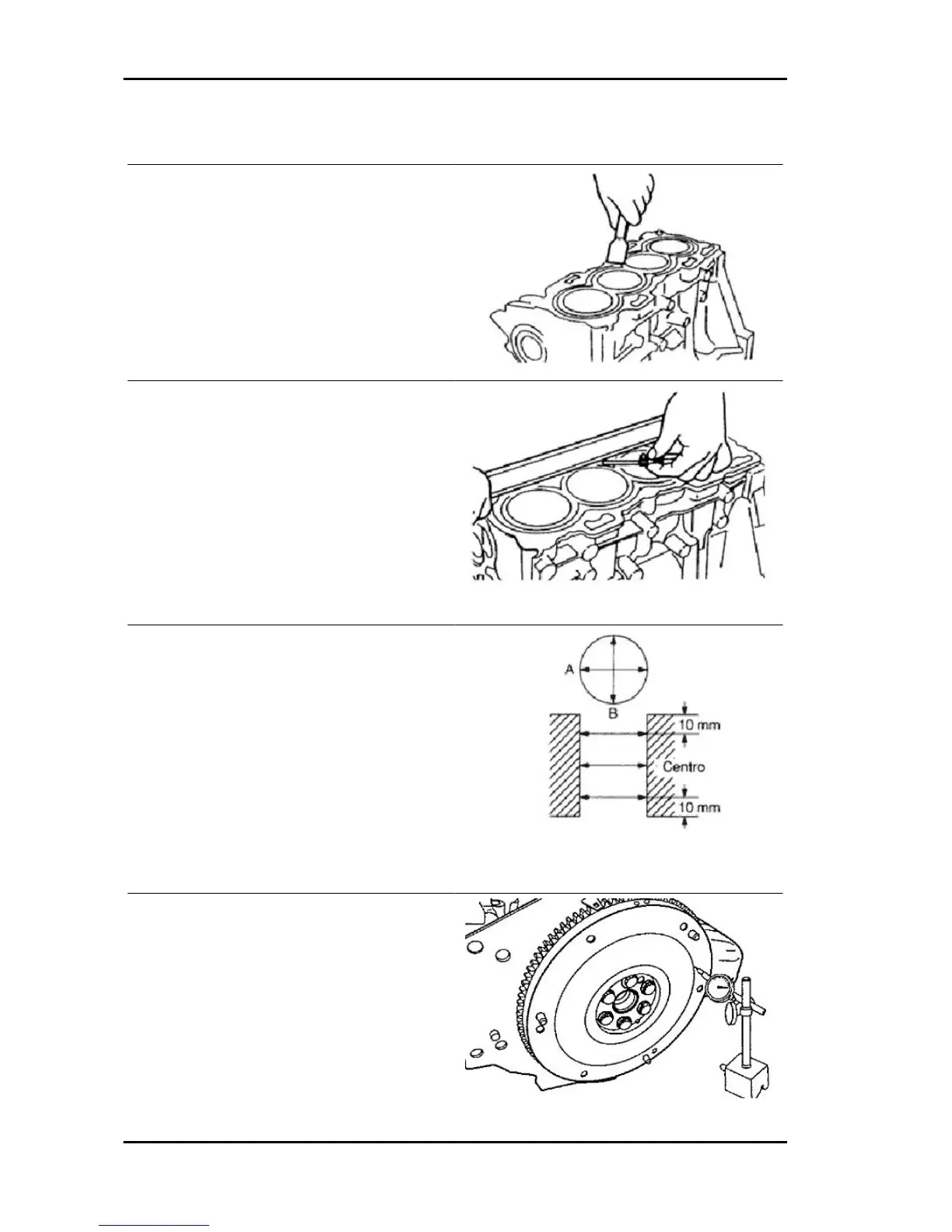

1. Removing gasket residues.

Remove all gasket residues from the cylinder

block.

2. Cylinder block cleaning

Clean the cylinder block using a soft brush and

solvent.

3. Cylinder block upper surface check.

Check for any deformation of the head gasket con-

tact surface, using a precision scale and a thick-

ness gauge.

If unevenness exceeds the limit allowed, replace

the cylinder block.

Characteristic

Maximum unevenness:

0.10 mm

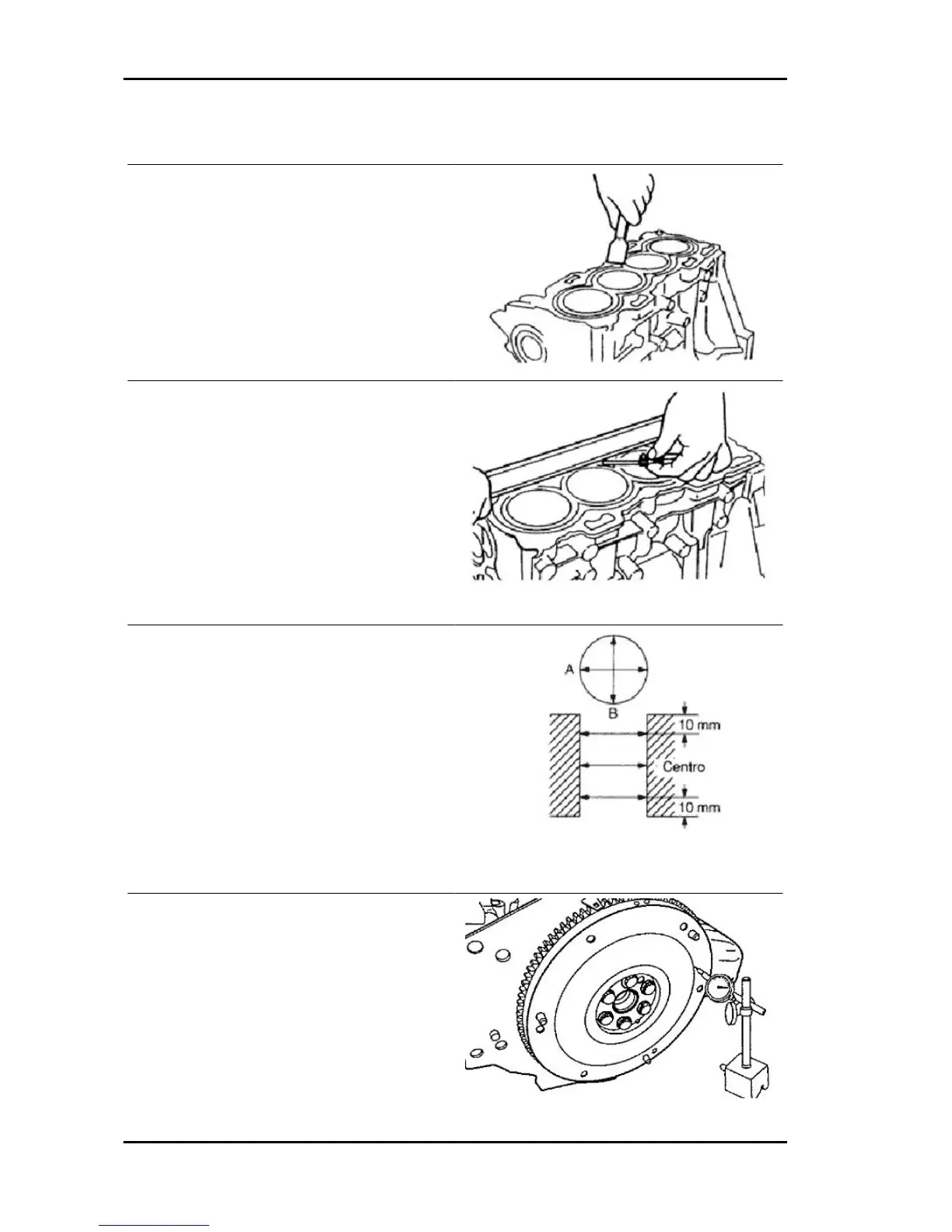

4. Cylinder check

Measure the diameter of each cylinder, at six

points a shown in the figure.

Make sure that the difference between the maxi-

mum and the minimum diameter of each cylinder

is within 0.1 mm. If the difference between the

maximum and the minimum value exceeds 0.1

mm, ream and/or grind the cylinder hole.

The grinding angle is 35° ± 5°. Surface roughness

is 1 - 4Z.

Reference:

The table indicated below identifies the cylinder

diameter when oversized pistons are used. Meas-

ure the oversized piston diameter. Continue with

the cylinder finishing according to the piston diam-

eter.

•

Measure the diameter of each cylinder

in the position shown in the figure. The

Engine PORTER 1.3 16V

EN - 310

Loading...

Loading...