3. End clearance measurement

With thickness gauge, measure clearance be-

tween the end (tip) of the internal rotor and that one

of the external rotor.

REPLACE THE ROTOR SERIES IF CLEARANCE EXCEEDS

THE PRESCRIBED VALUE.

Characteristic

Clearance

0.16 - 0.24

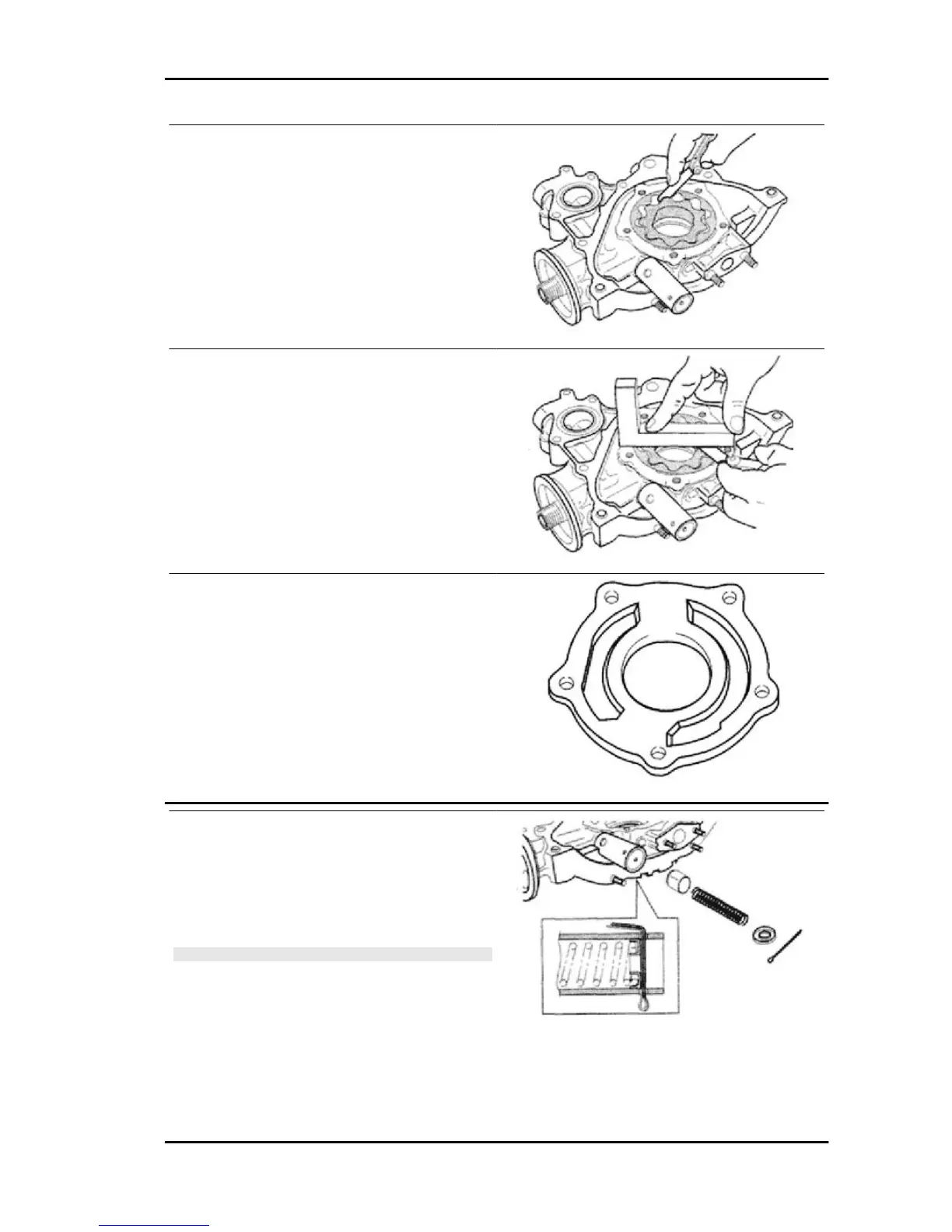

4. Side clearance measurement

With a rectified bar section and a thickness gauge,

measure side clearance between rotors and the oil

pump housing.

REPLACE THE OIL PUMP IF CLEARANCE EXCEEDS THE

PRESCRIBED VALUE.

Characteristic

Maximum clearance allowed:

0.04 - 0.08 mm

WEAR CHECK

Check if the pump cover rotor series connection

surface is worn.

- REPLACE THE OIL PUMP COVER IF WORN.

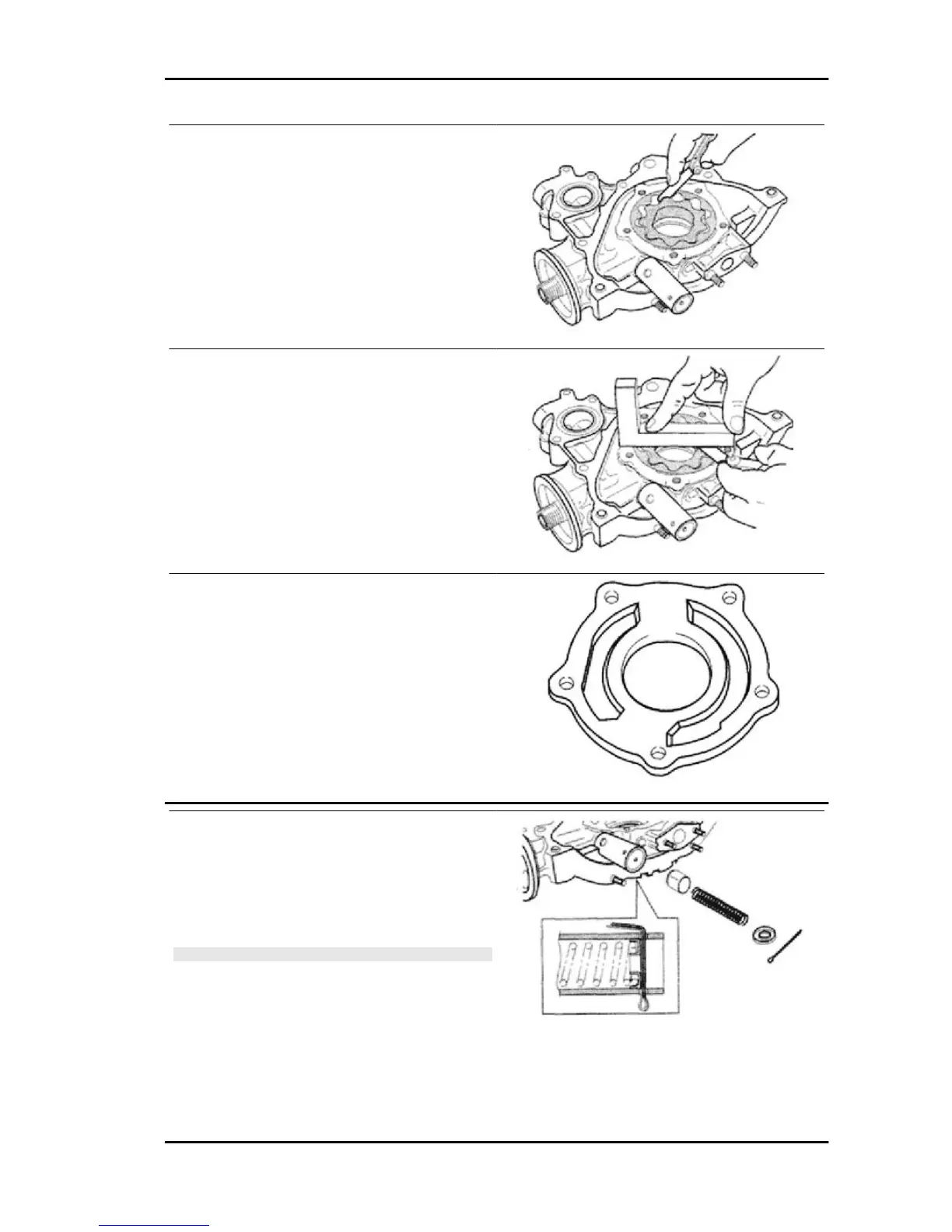

Fitting

1. Apply engine oil onto the valve and insert, af-

terwards, the valve inside the oil pump body.

2. Insert the compression spring and or the spring

retaining cap inside the oil pump body.

N.B.

- WASH THOSE PARTS TO BE FITTED USING SOLVENT

FOR CLEANING. DRY THEM BLOWING COMPRESSED

AIR. - WHEN COMPRESSED AIR IS USED, PROTECT EYES

BY WEARING PROTECTIVE GOGGLES. - FIT THE SPRING

RETAINING CAP SO THAT THE PROTRUDING PART IS

PLACED ON THE COMPRESSION SPRING SIDE.

PORTER 1.3 16V Engine

EN - 353

Loading...

Loading...