Lenze · 8400 HighLine · Reference manual · DMS 12.0 EN · 06/2017 · TD23 499

8 Basic drive functions (MCK)

8.2 Internal interfaces | System block "LS_MotionControlKernel"

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

In the interconnection previously shown, the Motion Control Kernel monitors every interface. Some

of the signals such as a quick stop request or a DC-injection braking request are directly passed

through to the motor control. However, other signals are passed through or modified depending on

the operating mode (e.g. synchronising a setpoint selection via ramp function).

8.2 Internal interfaces | System block "LS_MotionControlKernel"

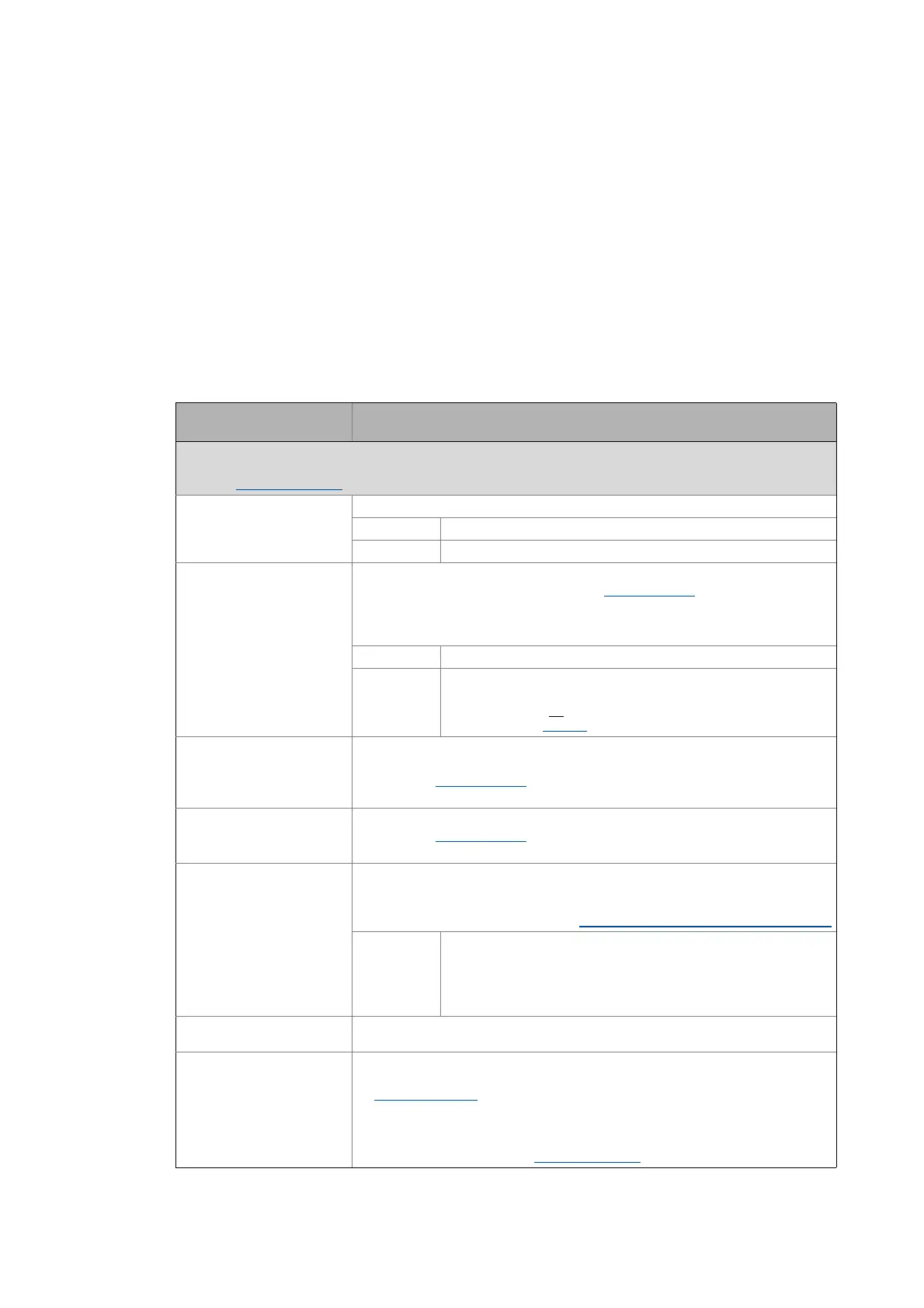

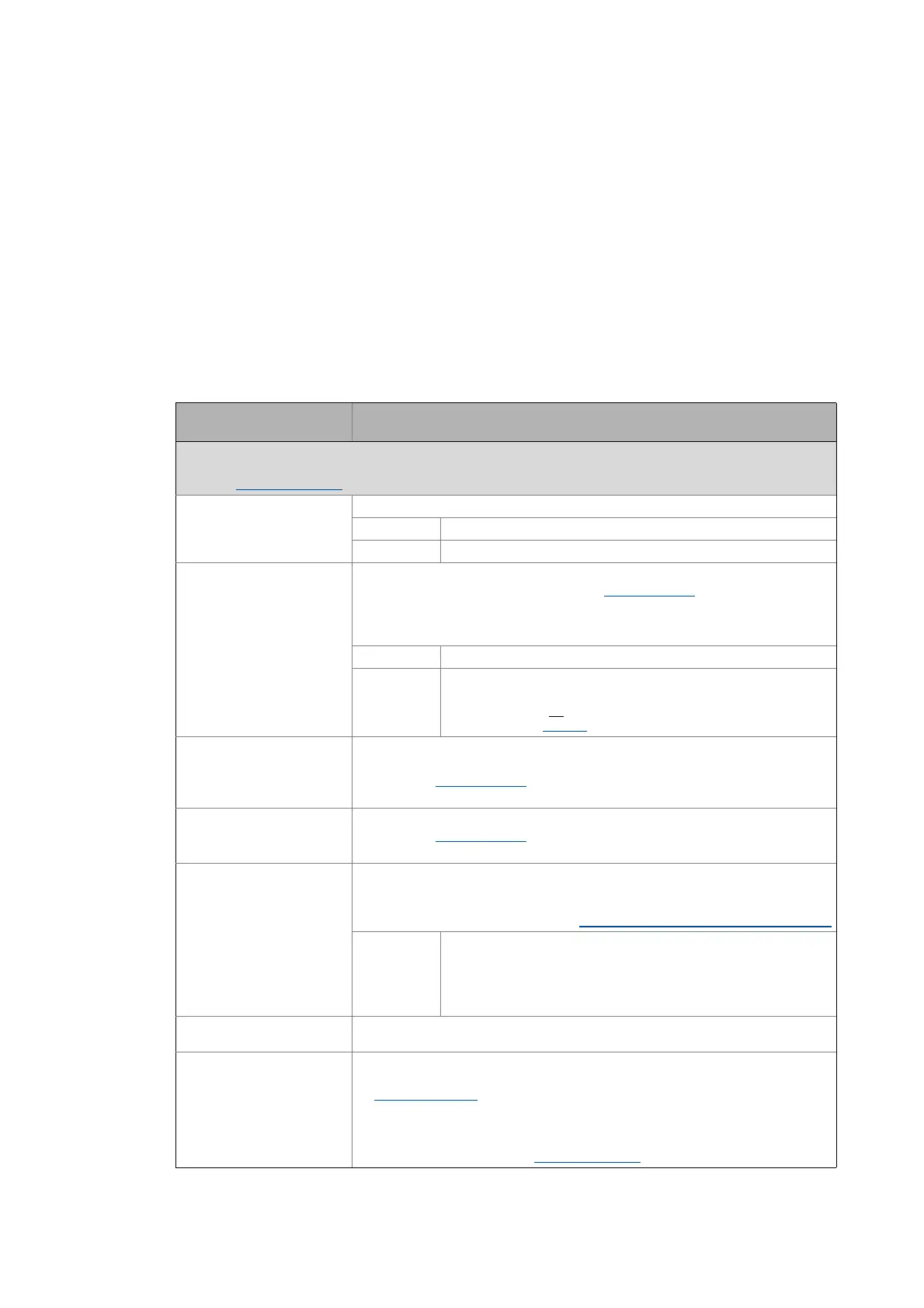

In the Function Block editor, the system block LS_MotionControlKernel provides the interfaces to

the Motion Control Kernel.

Inputs

Designator

Data type

Information/possible settings

Control and setpoint signals for motor control

The purpose of the following inputs is to transfer control signals and setpoints to the internal motor control

function (LS_MotorInterface

).

bPosCtrlOn

BOOL

Activation of position/angle control

FALSE Position/angle control deactivated.

TRUE Position/angle control activated.

bDeltaPosOn

BOOL

Activate position difference as setpoint selection

• In order to position the motor shaft, the position control

function can work

within the motor control function with the absolute position setpoint

dnPosSetValue_p or alternatively with the speed setpoint nSpeedSetValue_a and

the position difference dnDeltaPos_p.

FALSE Positioning with position setpoint dnPosSetValue_p.

TRUE Positioning with speed setpoint nSpeedSetValue_a and position

difference dnDeltaPos_p.

Note: In this case, no

position encoder should be set to ensure a

correct function (C00490

= "No encoder: nSpeedSetValue_a").

dnDeltaPos_p

DINT

Position difference (following error input)

• Difference between setpoint position and actual position in [increments]

•Is used for position control

if bDeltaPosOn = TRUE.

• Scaling: A revolution is displayed with 65536 increments or steps.

dnPosSetValue_p

DINT

Absolute position setpoint in [increments]

•Is used for position control

if bDeltaPosOn = FALSE.

• Scaling: A revolution is displayed with 65536 increments or steps.

bPosDerivativeOn

BOOL

Create a setpoint for the speed controller from the position setpoint

• For highly dynamic control systems, the setpoint for the speed controller can be

created from the absolute position setpoint dnPosSetValue_p instead of the

speed setpoint nSpeedSetValue_a Position control/additive speed specification

TRUE Create a speed setpoint from the position setpoint.

• The absolute position setpoint dnPosSetValue_p is differentiated

and a speed value is created which is the setpoint for the speed

controller.

• Internal limitation of 65536 increments/ms.

bReserved01

BOOL

Reserved

dnPosRefValue_p

DINT

Home position in [increments]

• Value is adopted when control bit 9 ("HomeSetPos") is set from "0" to "1" in the

MCK control word

and is sent to the motor control function via the

dnMotorRefOffset_p_ output.

• Transfer is possible in any operating mode ("Homing on the fly").

• For this function, the dnPosRefValue_p_ output must be connected to the input

of the same name of the SB LS_MotorInterface

.

Loading...

Loading...