2008T Troubleshooting Guide

P/N 490292 Rev. A

F- 9.0.24 ISOLATE FLOW PUMP INPUT FLOW

a) Obtain a 1000 ml (or larger) graduated cylinder!

b) Service Mode’s Flow Pressure is used to isolate the Flow Pump’s input circuit!

DO NOT follow the screen instructions! Perform no adjustments until instructed!

c) Enter Service Mode → Calibrate Hydraulics → Flow Pressure.

d) Press ‘Enter’ THEN ENSURE the FLOW MOTOR shaft

is rotating!

e)

NOTE the gauge reading for later.

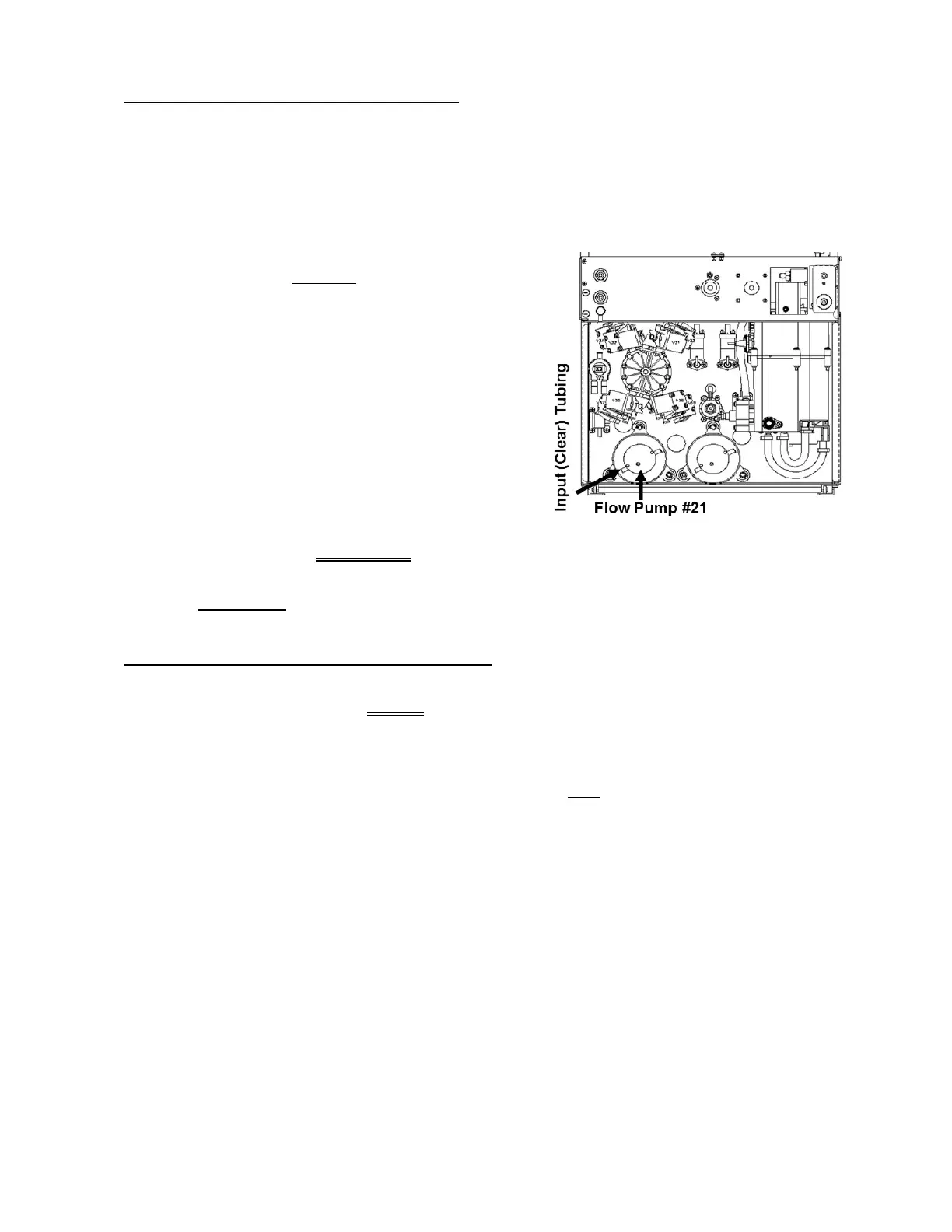

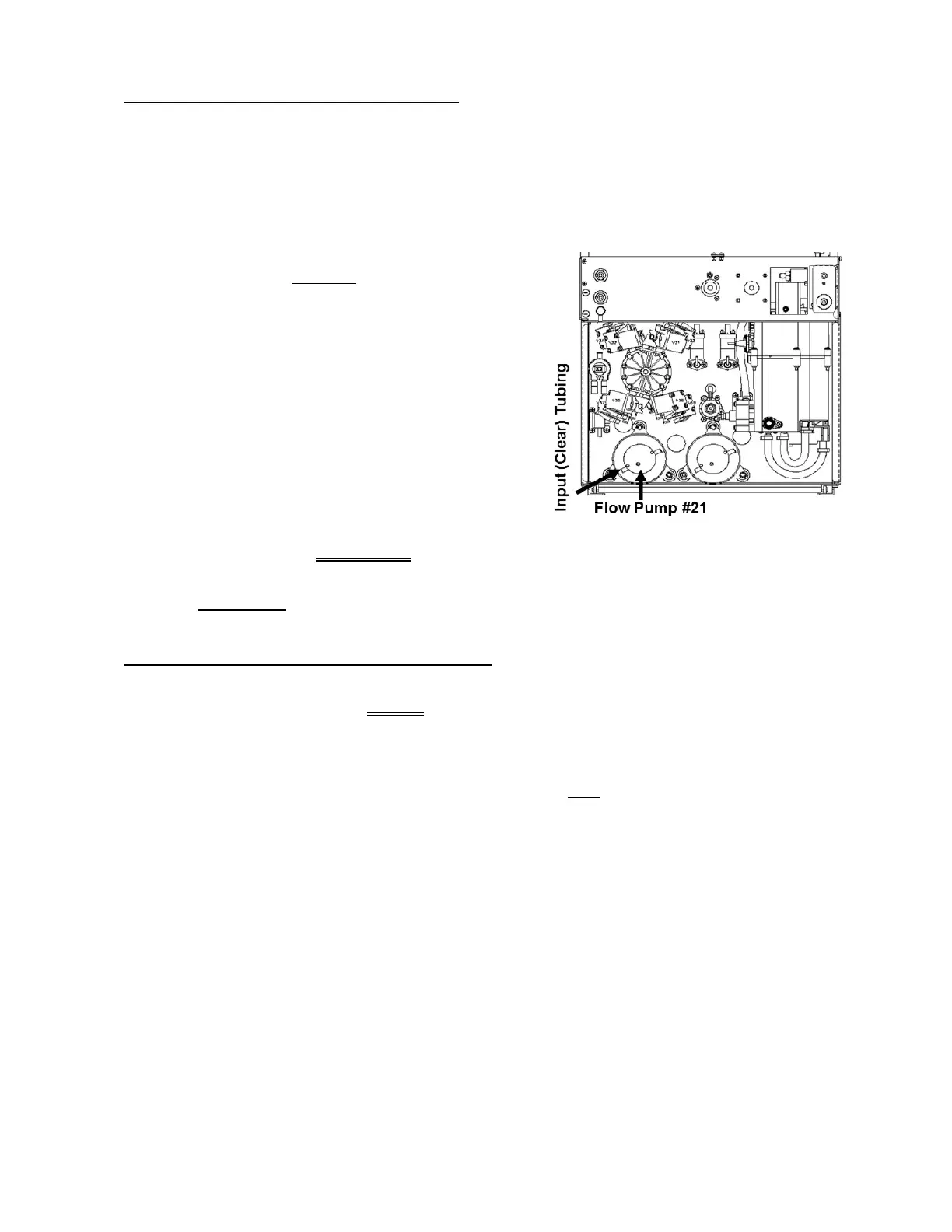

f) Figure right, remove the Flow Pump’s INPUT (clear)

tubing and measure flow from it for one (1) minute.

g) Press ‘Enter’ to return to “Calibrate Hydraulics”.

h) Reattach the Flow Pump’s tubing!

i) TWO (2) possible scenarios:

1) IF (and ONLY if) MORE THAN 800 ml collected! See procedure number F- 9.0.25 (page 102).

2) IF LESS THAN 800 ml collected! Proceed to page 105, procedure number F- 9.0.4.

F- 9.0.25 INPUT FLOW PUMP MORE THAN 800 ML

a) Place the machine into RINSE!

b) As noted above, was pressure between 35 and 36 psi?

Yes Between 35 and 36 psi! Good static pressure but NOT dynamic! TWO (2) possible bad

components: 1) Bad Flow Pump head OR; 2) Bad Flow Pump motor (possibly brushes).

No Less than 35 psi! See procedure number F- 9.0.26 (page 103).

Loading...

Loading...