2008T Troubleshooting Guide

P/N 490292 Rev. A

F- 10.0.0 BAD ACFS SIGNAL

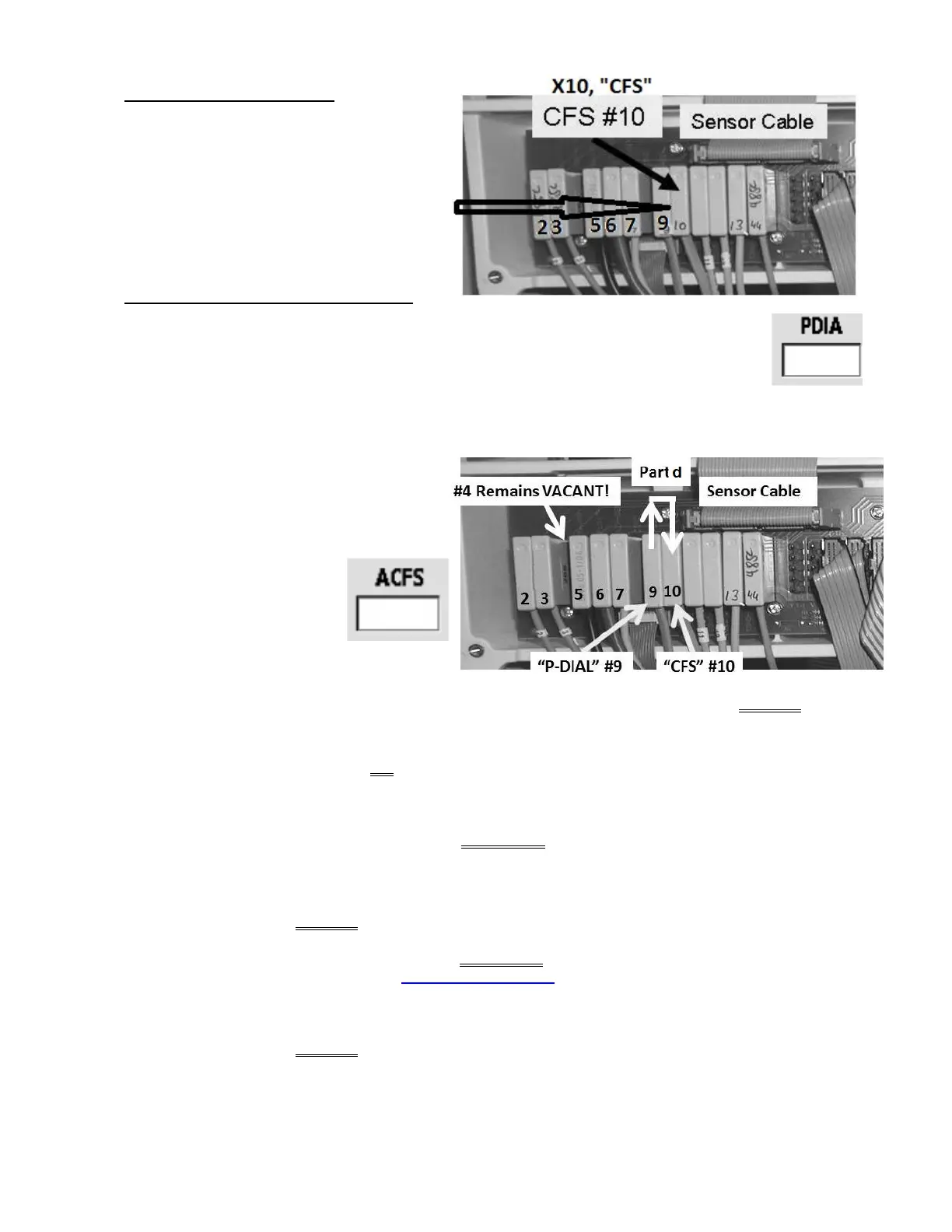

a) Figure right, ENSURE the CFS #10

Pressure Transducer’s connector is

plugged PROPERLY into the

distribution board.

b) See procedure number F- 10.1.0

(page 111).

F- 10.1.0 CFS PLUGGED IN PROPERLY

a) Call debug screen 10. If all procedures were performed correctly PDIA (middle column)

= between 3.5 and 6.5.

b) Unplug the CFS’s connector from position X10, “CFS”.

c) Using a flashlight, check inside the vacant “X10” position. If corrosion or damaged pins are located

this may be the problem!

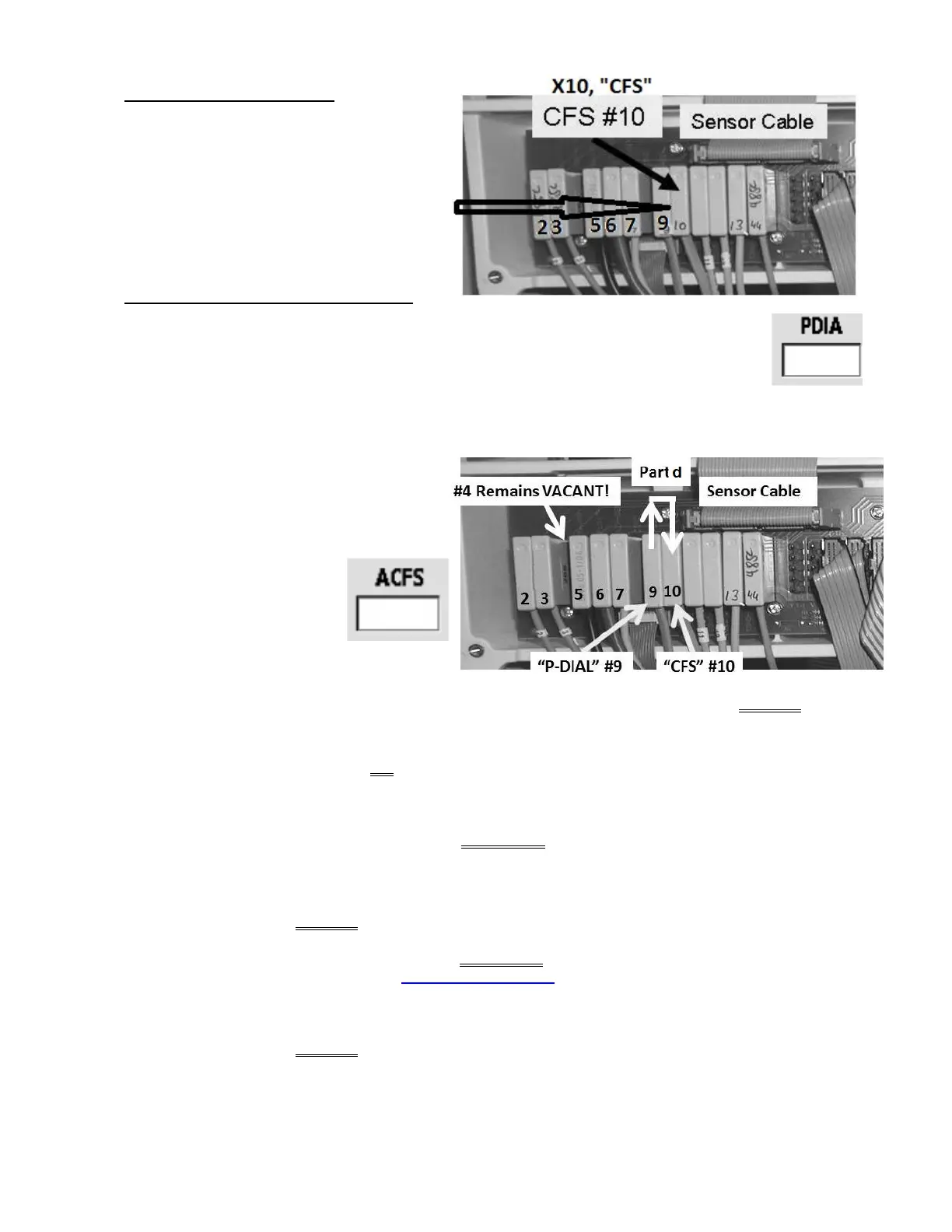

d) Figure right, plug the Dialysate

Pressure Sensor’s (#9) connector

into the CFS Pressure Sensor’s. “P-

DIAL” → “CFS”.

e) Does

ACFS (lower

right) go to between 4.0

and 6.0?

Yes ACFS between 4.0 and 6.0! The CFS Pressure Sensor #10* is bad. *To LOCATE the

CFS Pressure Sensor #10 refer to Figure 21 (page 100).

No ACFS is less than 4.0 OR more than 6.0! Leaving PDIA in CFS for now, FIVE (5) possible bad

components: 1) Bad Actuator-Test Board

a

OR; 2) Bad Sensor Board

b

OR; 3) Bad Sensor

Board cable OR; 4) Bad distribution board OR;5) Bad motherboard.

a

A) With the power off, swap in a known good Actuator-Test

1

Board; B) IMPORTANT!

Return Dialysis Program (“Select Program” → ‘Dialysis’ → ‘Enter’); C) If ACFS is between

4.0 and 6.0 the previous Actuator-Test Board is bad.

1

To LOCATE the board refer to Figure 4A (page 10).

b

A)

With the power off, swap in a known good Sensor Board

2

; B) Place the machine into

T and C Mode (refer to OPERATING MODES (page 19); C) IMPORTANT! Return to

Dialysis Program)!; D) If ACFS now = between 4.0 and 6.0 the previous Sensor Board is

bad.

2

To LOCATE the Sensor board see Figure 4A (page 10).

Loading...

Loading...