2008T Troubleshooting Guide

P/N 490292 Rev. A

F- 1.0.8 LOADING PRESSURE IS NOT ‘OKAY’ (2)

FIVE (5) possible scenarios 1) or 2) or 3) or 4) or 5) below:

1) IF (and ONLY if) EVER MORE THAN 29 psi: Proceed to

page 36, procedure number F- 1.0.9.

2) IF (and ONLY if) REMAINS LESS THAN 15 psi: A) Remove the gauge THEN again SLAM it into

the RINSE port; B) If still REMAINS less than 15 psi proceed to page 124, procedure number

F- 15.0.0.

3) IF (and ONLY if) PEAKS to between 15 and 22 psi but cycles below 11 psi: See procedure

number F- 1.0.8.11 (page 35).

4) IF (and ONLY if) PEAKS to between 23 and 27 psi but cycles below 11 psi: See procedure

number F- 1.0.8.11 (page 35).

5) IF PEAKS to between 15 and 22 psi AND NEVER cycles below 11 psi: NOTING how many turns,

turn Loading Pressure Valve #65’s nut* CLOCKWISE until if a PEAK pressure of between 23 and 25

psi is achieved. TWO (2) possible scenarios 1) or 2) below:

* To LOCATE Valve #65 refer to Figure 6 (page 22)

1) IF (and ONLY if) between 23 and 25 psi CANNOT be achieved: Return Valve #65’s

screw to its ORIGINAL location then proceed to page 124, procedure number F- 15.0.0.

2) IF between 23 and 25 psi CAN BE achieved: See parts a THROUGH c below:

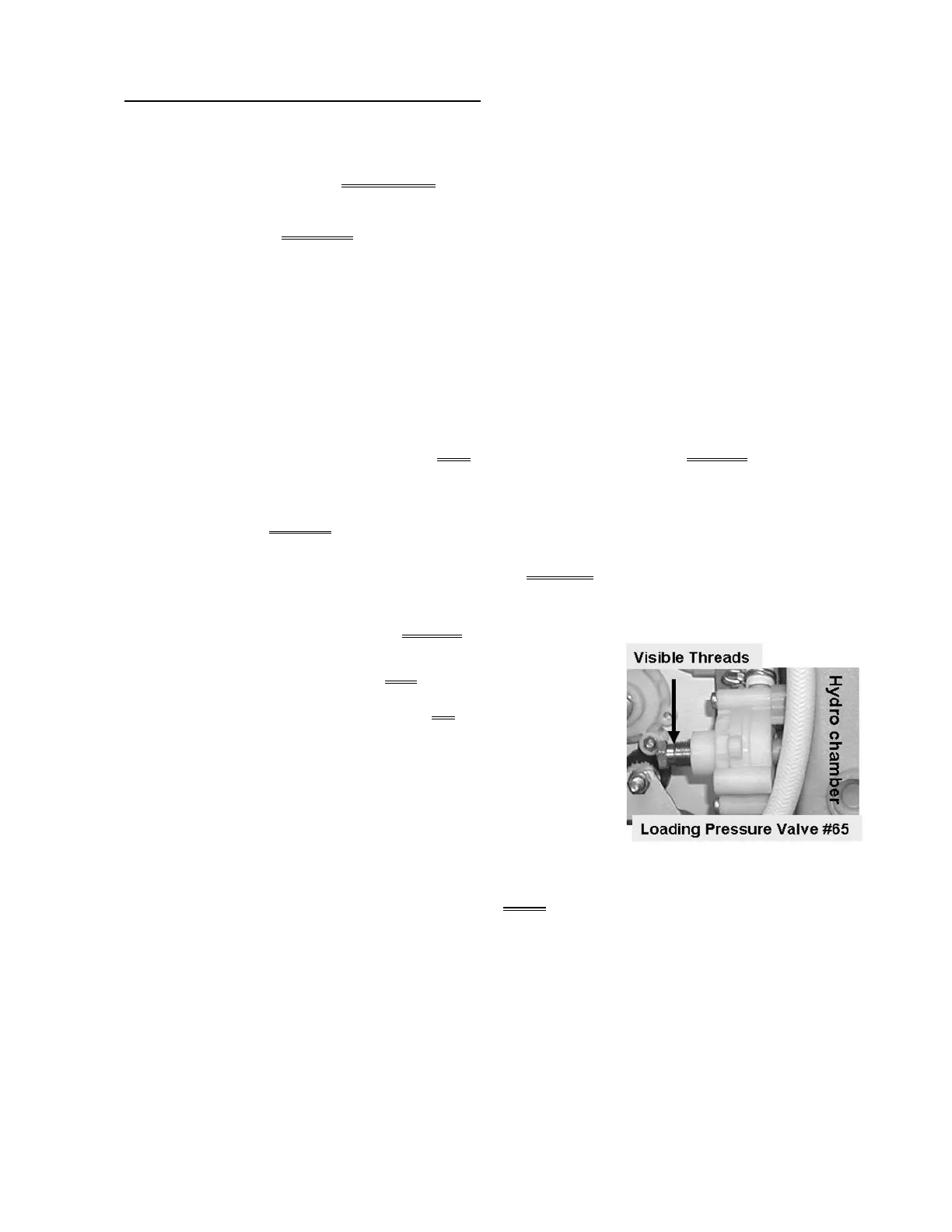

a) Figure right, if threads ARE visible under Valve #65’s

nut see part b. If no threads are visible is installed either

the wrong spring* is installed OR Valve #65 is bad.

* Refer to Figure 6 (page 22)

b) Call debug screen 0.

c) WITHOUT LOOKING AWAY, watch Flow Error (Top

window) for up to five (5) minutes OR until if it EVER = 1

indicating a Flow Problem. TWO (2) possible scenarios:

1) IF (and ONLY if) Flow Error EVER = 1, even just once: Return to (ABOVE)

procedure number F- 1.0.5 (page 30).

2) IF Flow Error REMAINS = 0: A flow problem is NOT occurring at this time but other

problems may be! Refer to the Table of Contents for whatever other problem may be

occuring.

Loading...

Loading...