2008T Troubleshooting Guide

P/N 490292 Rev. A

F- 3.2.0 SIX HUNDRED (600) ML OR MORE IN FILLING PROGRAM

a) This procedure uses a psi gauge. ENSURE it reads 0 psi before installing it.

b) Return BOTH concentrate connectors to their RINSE ports!

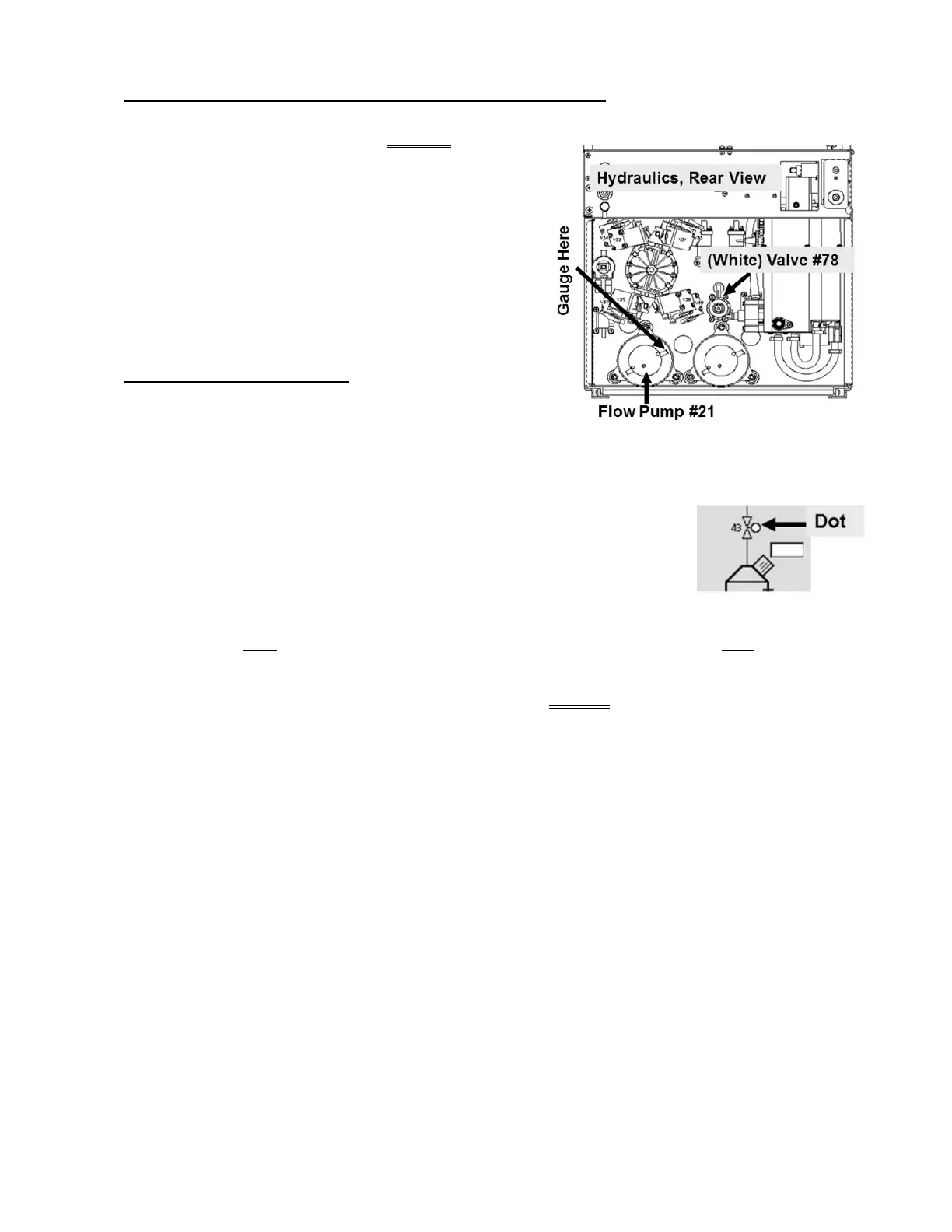

c) Figure right, tee the gauge between the Flow Pump's

OUTPUT nozzle and its WHITE tubing.

d)

To prevent leaks and false readings, tie

wrap both sides of the gauge tubing.

e) See procedure number F- 3.2.2 (page 50).

F- 3.2.2 ISOLATE FLOW PUMP

a) IMPORTANT! Place the machine in RINSE!

b) Watch for one (1) minute to ENSURE a “No Water” alarm NEVER occurs!

c) Call debug screen 0. If debug does not appear press ‘Esc’ then call screen 0.

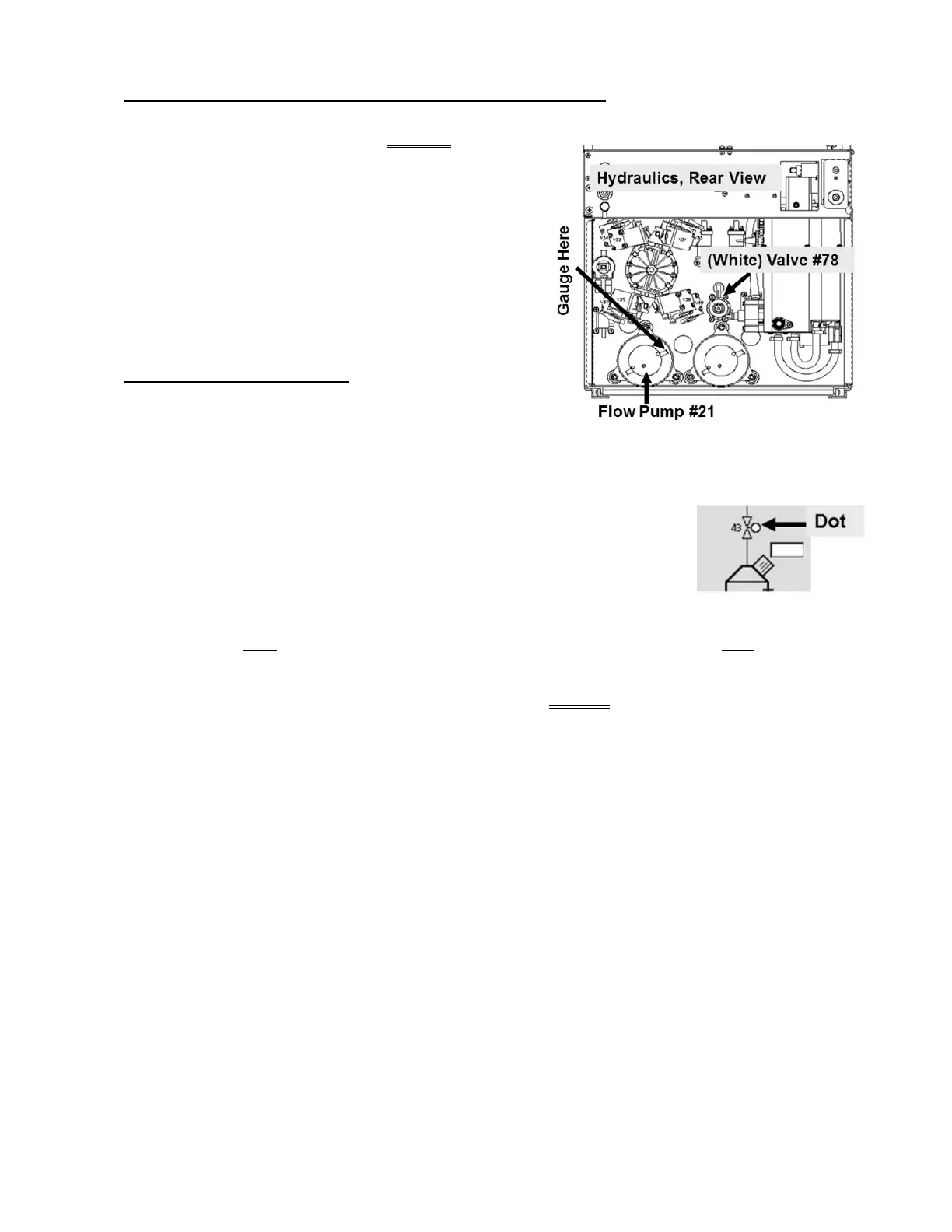

d) Allow Valve #43’s ‘dot’ (Figure right) to turn blue then WHITE again! While

white, does pressure CYCLE, about every three (3) seconds, to between 35

and 36 psi?

Yes Between 35 and 36 psi! See procedure number F- 3.3.0 (page 51).

No Is NOT between 35 and 36 psi! ENSURING the machine was in RINSE AND no leaks, TWO

(2) possible scenarios below:

1) IF (and ONLY if) pressure is too low: DO NOT calibrate instead proceed to

page

101, procedure number F- 9.0.2.

2) IF pressure is too high: Perform parts a AND b below:

a) Per the Figure above, adjust Valve #78 until pressure cycles to between 35 and 36

psi!

b) See procedure number F- 3.3.0 (page 51).

Loading...

Loading...