2008T Troubleshooting Guide

P/N 490292 Rev. A

TROUBLESHOOTING VALVE ERRORS IN CLEANING PROGRAMS

A) To prevent damage, turn the machine OFF!

B)

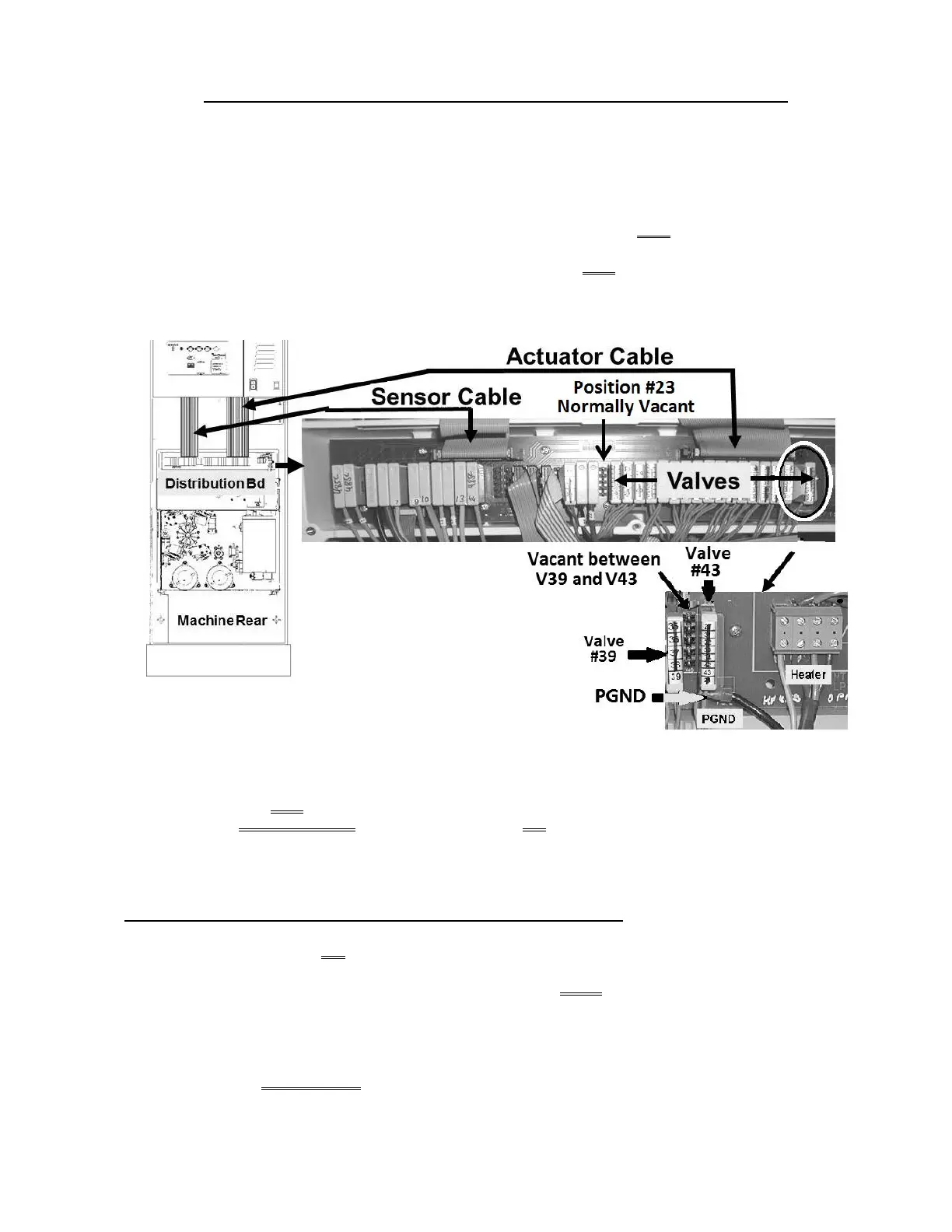

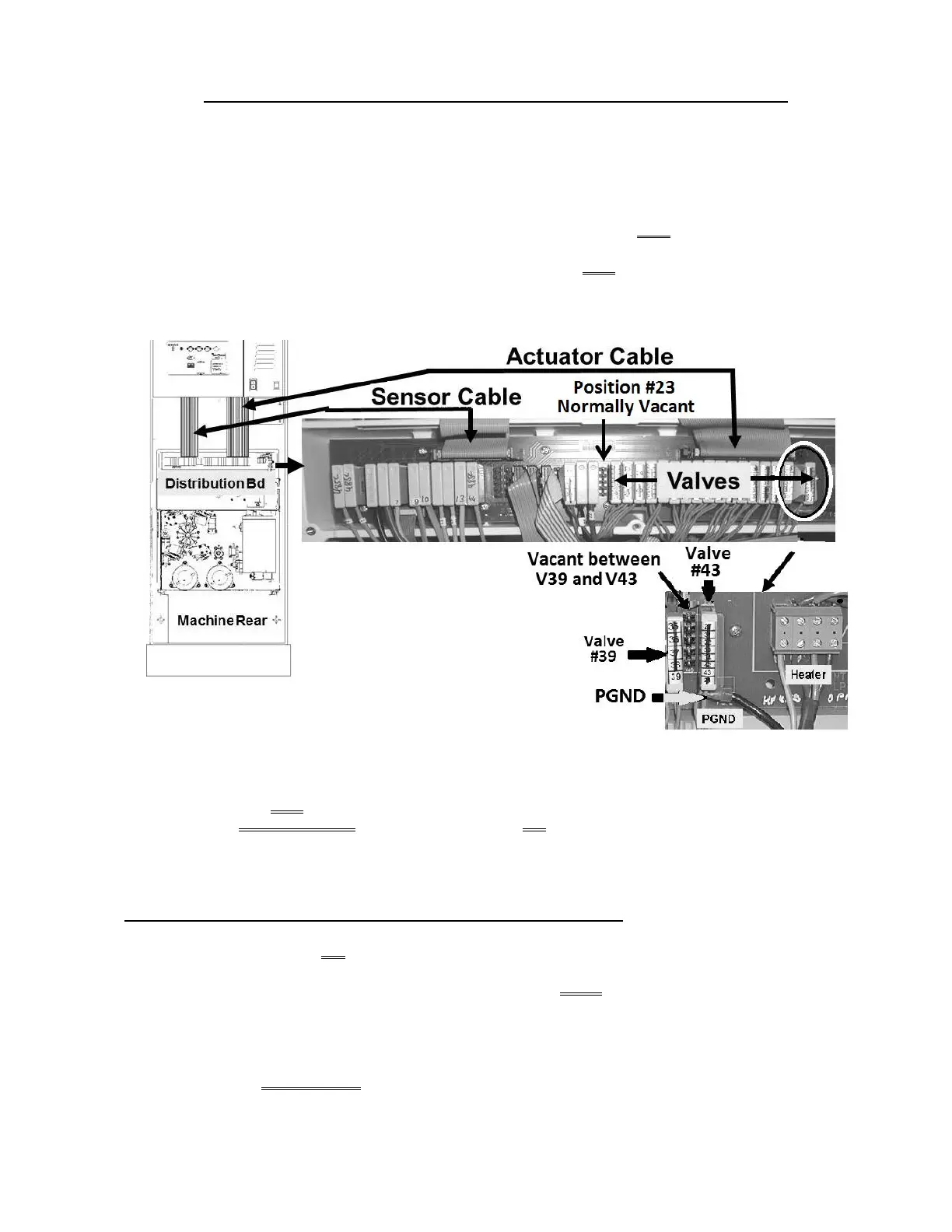

Per the Figure below, at the distribution board, THREE (3) checks:

Check #1: ENSURE the ACTUATOR CABLE is plugged in securely AND is not damaged!

Check #2: ENSURE the black PGND is plugged in securely AND shows no sign of burning!

Check #3: ENSURE all Valves are plugged PROPERLY into their distribution board positions

Figure 41 – Distribution Board

B) If a problem was NOT located in part A, see procedure number VEC- 1.0.0 (page 224). If a problem

was located AND REPAIRED return to Heat Disinfect OR Rinse. If VERR (debug screen 1) remains = 0

for five (5) minutes the problem has been eliminated. If VERR does NOT remain = 0 see procedure

number VEC- 1.0.0 (page 224).

VEC- 1.0.0 ISOLATE THE VALVE ERROR / FLOW THROUGH ‘BOB’?

a) Return to Heat Disinfect OR Rinse!

b) Watching for one (1) minute, does the flow indicator’s ’bob’ EVER rise, at least ¼ way up, in the sight

tube?

Yes ‘Bob’ moving! Proceed to

page 230, procedure number VEC- 2.0.0

No ‘Bob’ NOT MOVING! See procedure number VEC- 1.1.0 (page 225).

Loading...

Loading...