2008T Troubleshooting Guide

P/N 490292 Rev. A

CLEAN- 1.5.3 BIBAG EQUIPPED

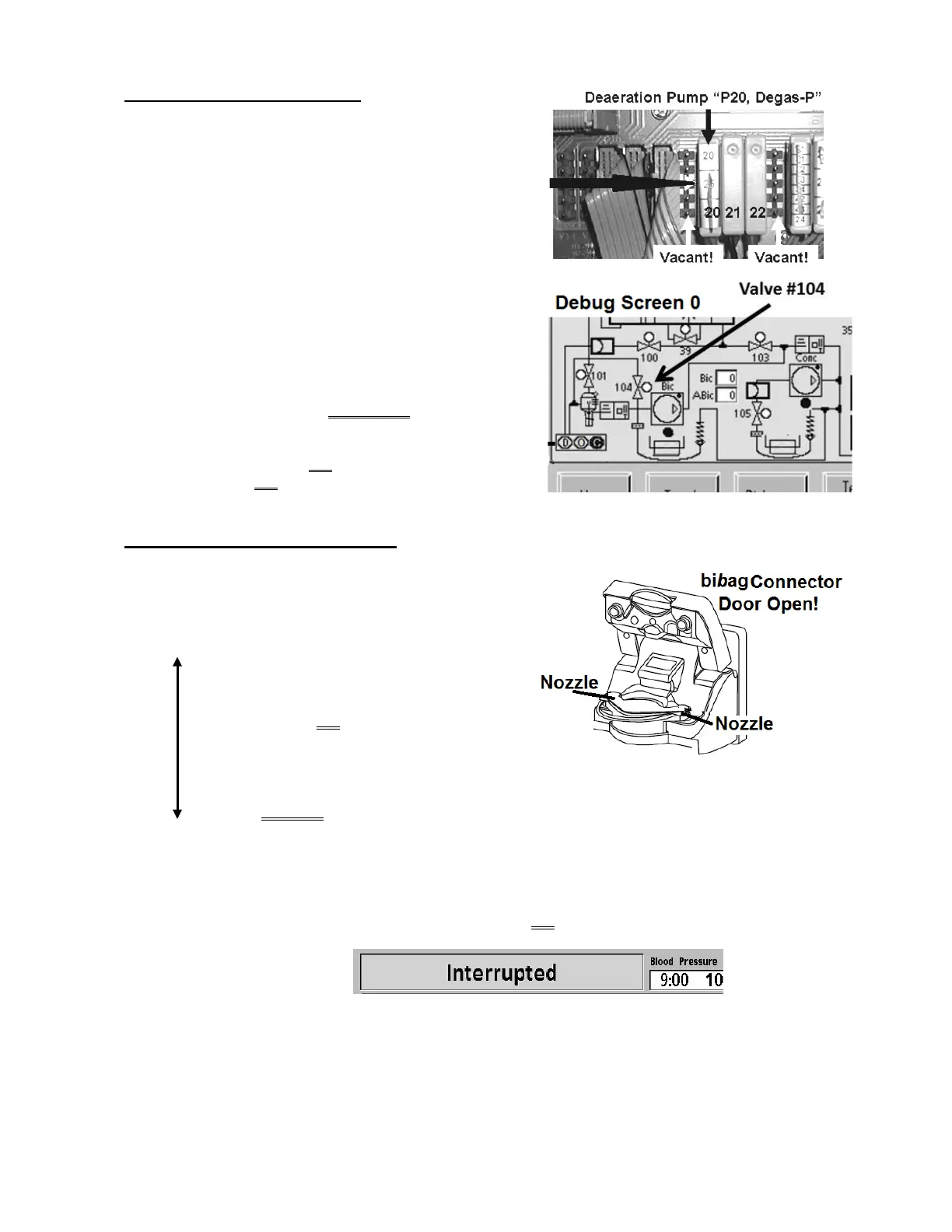

a) Figure right, return the Deaeration Pump to distribution

board position “P20”!

b)

ENSURE THE DEAERATION MOTOR IS

running!

c) Call debug screen 0 (Figure right). If debug does

not appear press ‘Esc’ then call screen 0.

d) Does Valve #104’s symbol appear?

Yes Valve #104 appears! See procedure

number CLEAN- 1.5.4 (page 178).

No Valve #104 does DOES NOT appear! THREE

(3) possible problems: 1) Loose bibag

Interface Board ribbon cable (refer to Figure

4C (page 11)) OR; 2) Bad bibag Interface

Board OR; 3) Bad Actuator-Test Board.

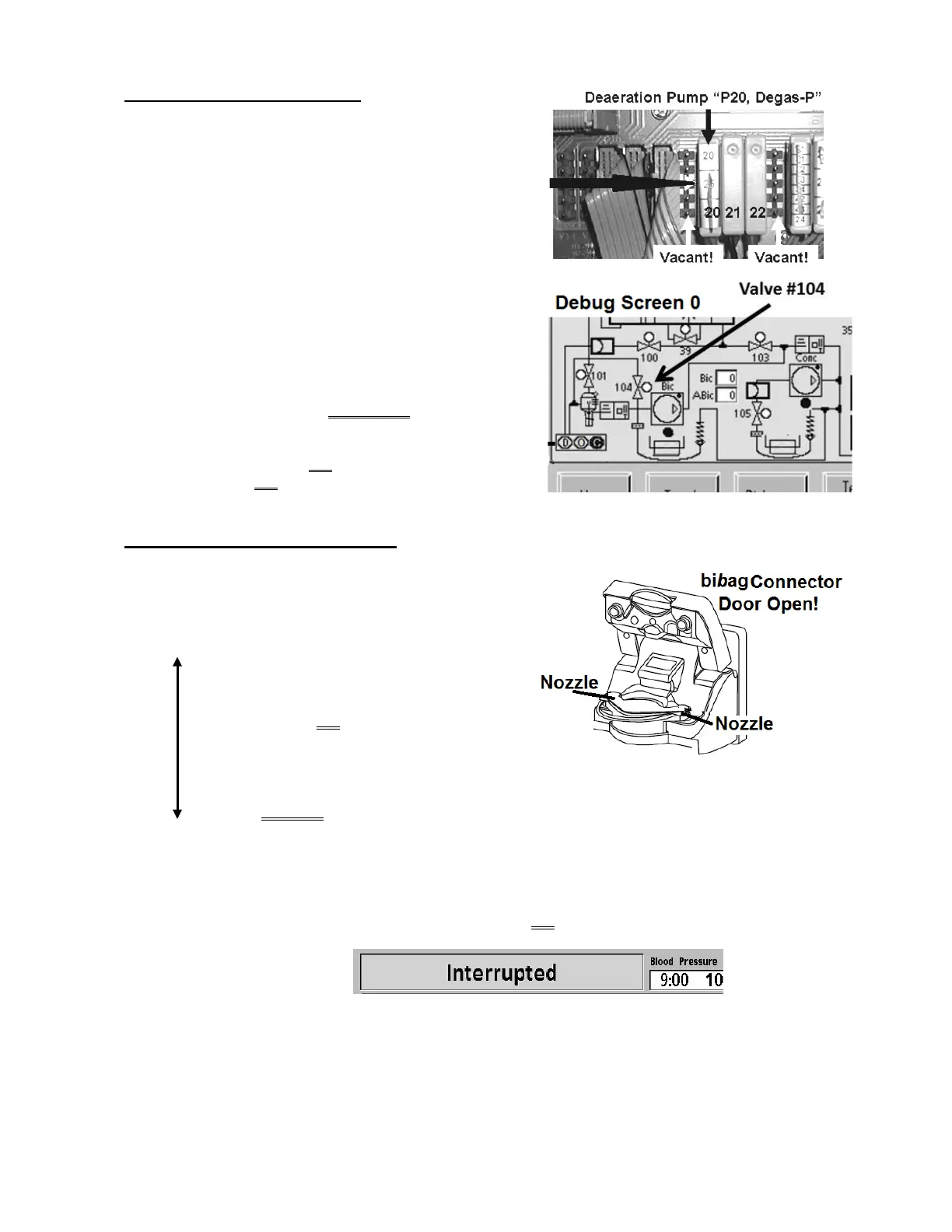

CLEAN- 1.5.4 VALVE #104 APPEARS

Figure right, open the bibag Connector door! Flow (more

than 10 ml per minute) from one of the nozzles?

Yes Flow from a bibag Connector nozzle!

THREE (3) possible problems: 1) Loose

bibag Interface Board cable connection

(refer to Figure 4C, page 11)) OR; 2) Bad

Valve #100** OR; 3) Bad bibag Interface

Board.

NOTE! Swap the components in one at a time until no flow from the Connector nozzle.

** To LOCATE Valve #100 refer to Figure 3 (page 5)

No flow a) Close the bibag Connector door.

b) If the “Interrupted” banner (Figure below) IS NOT displayed continue to part c. If

“Interrupted” is displayed press ‘Esc’ then, depending on where the Flow Error was

occurring, return to HEAT DISINFECT OR RINSE!

c) See procedure number CLEAN- 1.5.41 (page 179).

Loading...

Loading...