2008T Troubleshooting Guide

P/N 490292 Rev. A

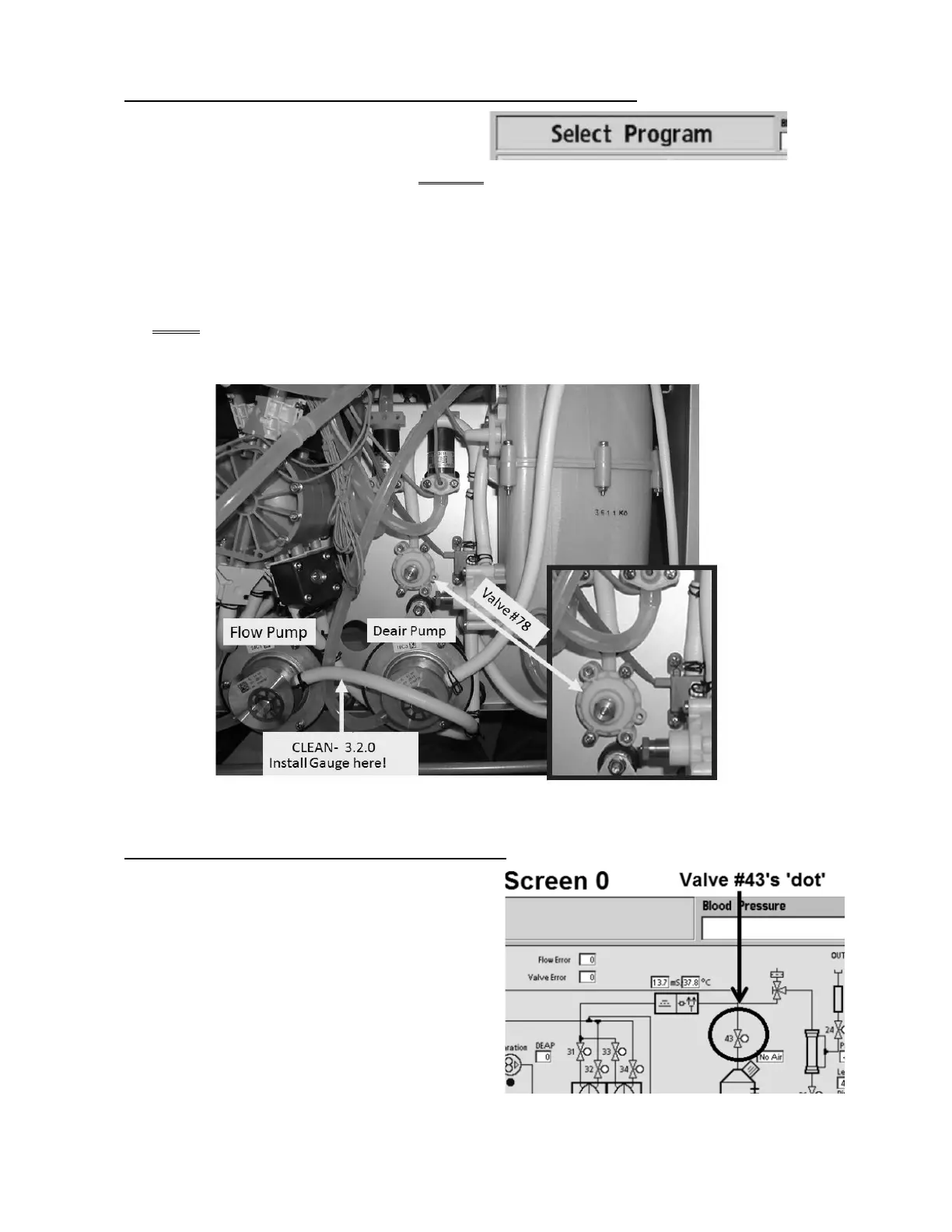

CLEAN- 3.2.0 MOTORS OKAY / ISOLATE FLOW PUMP PRESSURE (1)

a) ENSURE the “Select Program” banner is up!

b) A psi pressure gauge is required next. ENSURE it reads 0 before installing it!

c) Per the Figure below, tee the gauge into the OUTPUT (white tubing) side of the Flow Pump.

CAUTION! Fluid may be hot but won’t scald you!

d)

Tie wrap both sides of the gauge tubing to prevent leaks and false readings!

e) If (and ONLY if) the Flow Error was occurring in Heat Disinfect return to it. If not place the machine in

RINSE!

f) See procedure number CLEAN- 3.2.1 (page 191).

Figure 32 – Flow Pump / Valve #78

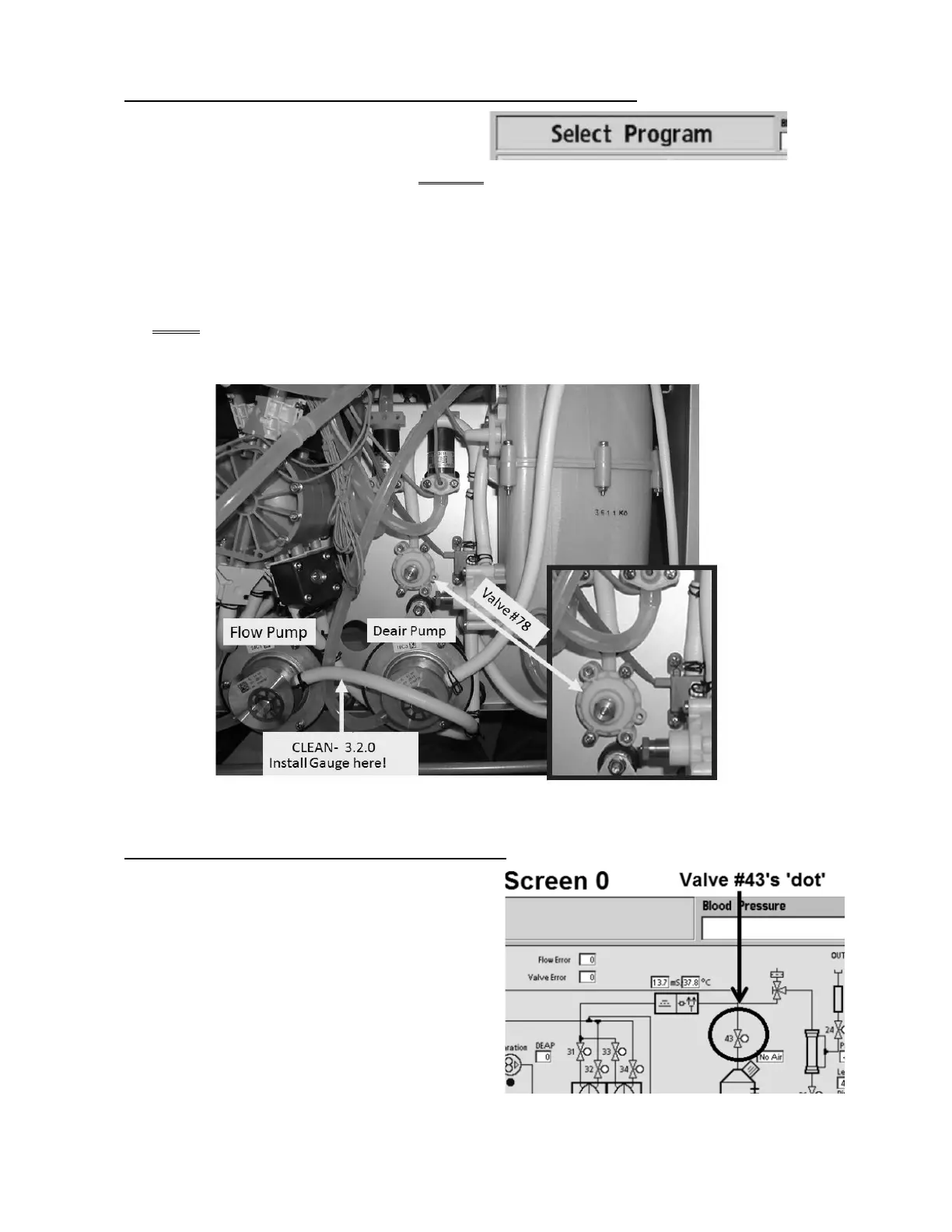

CLEAN- 3.2.1 ISOLATE FLOW PUMP PRESSURE (2)

a) Call debug screen 0 (Figure right). If debug does

not appear press ‘Esc’ then call screen 0.

b) Allow Valve #43’s ‘dot’ (Figure right) to turn blue

then WHITE again! While white, does gauge

pressure CYCLE, about every three (3) seconds,

to between 34 and 36 psi?

Loading...

Loading...