2008T Troubleshooting Guide

P/N 490292 Rev. A

c) ENSURE [Temperature] is still less than 35.0° C.

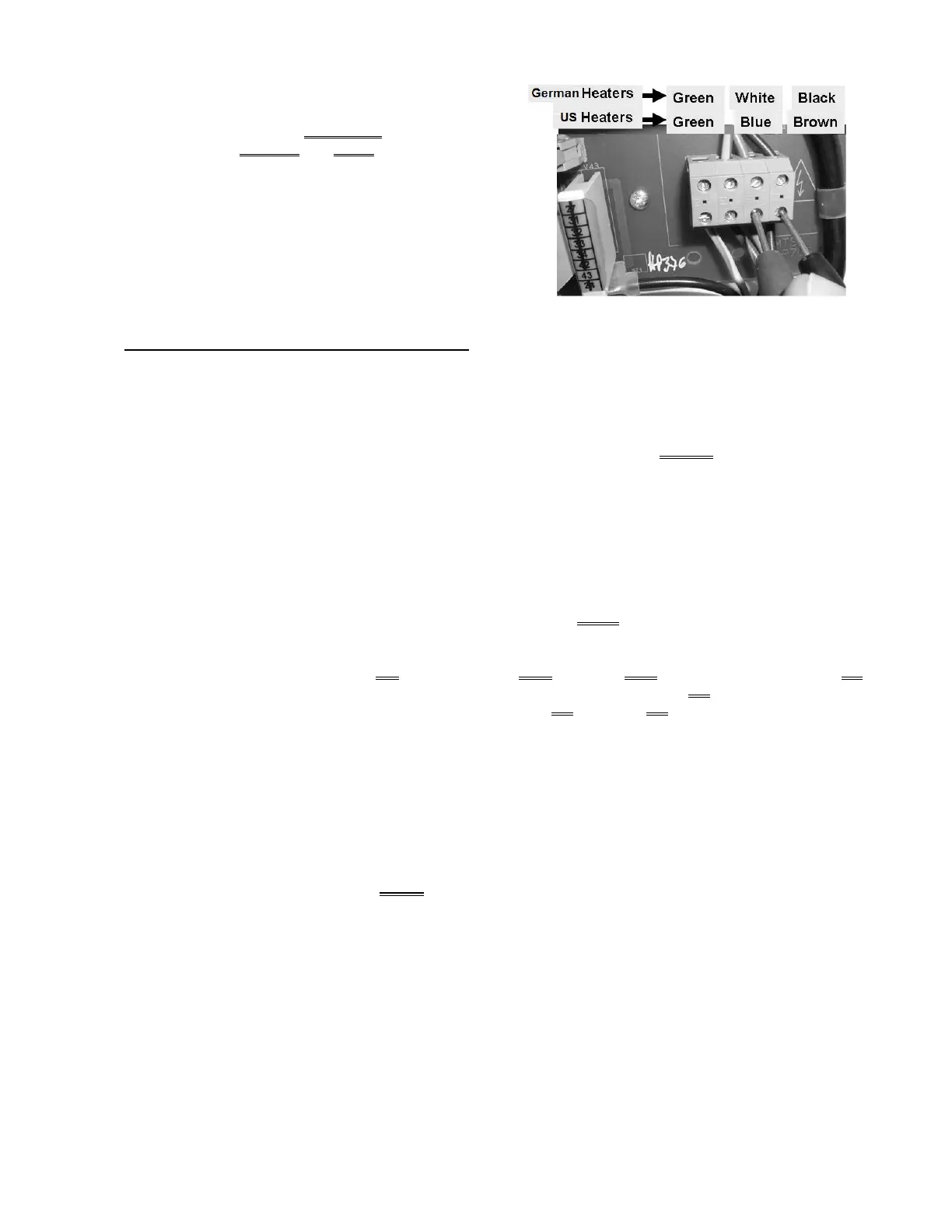

d) Figure right, measure BETWEEN the Heater

Connector’s BROWN and BLUE wires. TWO (2)

possible scenarios:

1) IF MORE THAN 100.0 volts! The heater is on!

See procedure number T- 2.0.4 (page 284).

2) IF LESS than 100.0 volts AC! Proceed to

page 295, procedure number T- 2.6.0.

T- 2.0.4 HEATER ON (MORE THAN 100 VOLTS)

a) Return NTC #2’s connector to the 1

st

distribution board position from the left,

“CON-NTC”.

b) Call debug screen 0. Watch for six (6) minutes to ENSURE Flow Error is NEVER = 1 and a “No Water”

NEVER occurs.

c) From the Home or Heat Disinfect screen, [Temperature] should increase to:

• IF in Dialysis Program: Between 35.0 and 39.0° C.

• IF in Heat Disinfect: After no more than thirty (30) minutes, more than 80° C!

d) The low temperature problem may be intermittent and occurs ONLY after the machine has been

running for a while with good temperature. In this event DO NOT turn the machine off!

e) ENSURING a “No Water” alarm OR a Flow Error are NOT occurring AND there is less than 10 volts AC

at the heater, unplug NTC #2. If heater voltage returns to more than 100 volts AC replace NTC #2. If

(and ONLY if) heater voltage remains less than 10.0 volts AC, TWO (2) DC voltage measurements

isolates the entire heater circuit:

Measurement #1: Per Figure 43 (page 281) at x2,

pin 6. Good = more than 9.6 volts DC.

Measurement #2: Per Figure 44 (page 282), at

T5’s TOP pin. Good = less than 2.0 volts DC.

f) TWO (2) possible scenarios:

Scenario #1: IF (and ONLY if) BOTH measurements are GOOD: All card cage signals are okay.

There is an intermittent problem with the Triac or the Power Control Board in the power

supply.

Scenario #2: IF a BAD signal is measured: TWO (2) possibilities: If (and ONLY if) the pin 6

measurement is less than 9.6 volts DC see procedure number T- 2.2.0 (page 292). If the

T5 measurement is more than 2.0 volts DC see procedure number T- 2.0.5 (page 285).

Loading...

Loading...