2008T Troubleshooting Guide

P/N 490292 Rev. A

F- 1.0.3 CHAMBER #69 SAYS “NO AIR” / TROUBLESHOOT FILLING PROGRAM FAILURE

a) To avoid damage turn the machine

OFF!

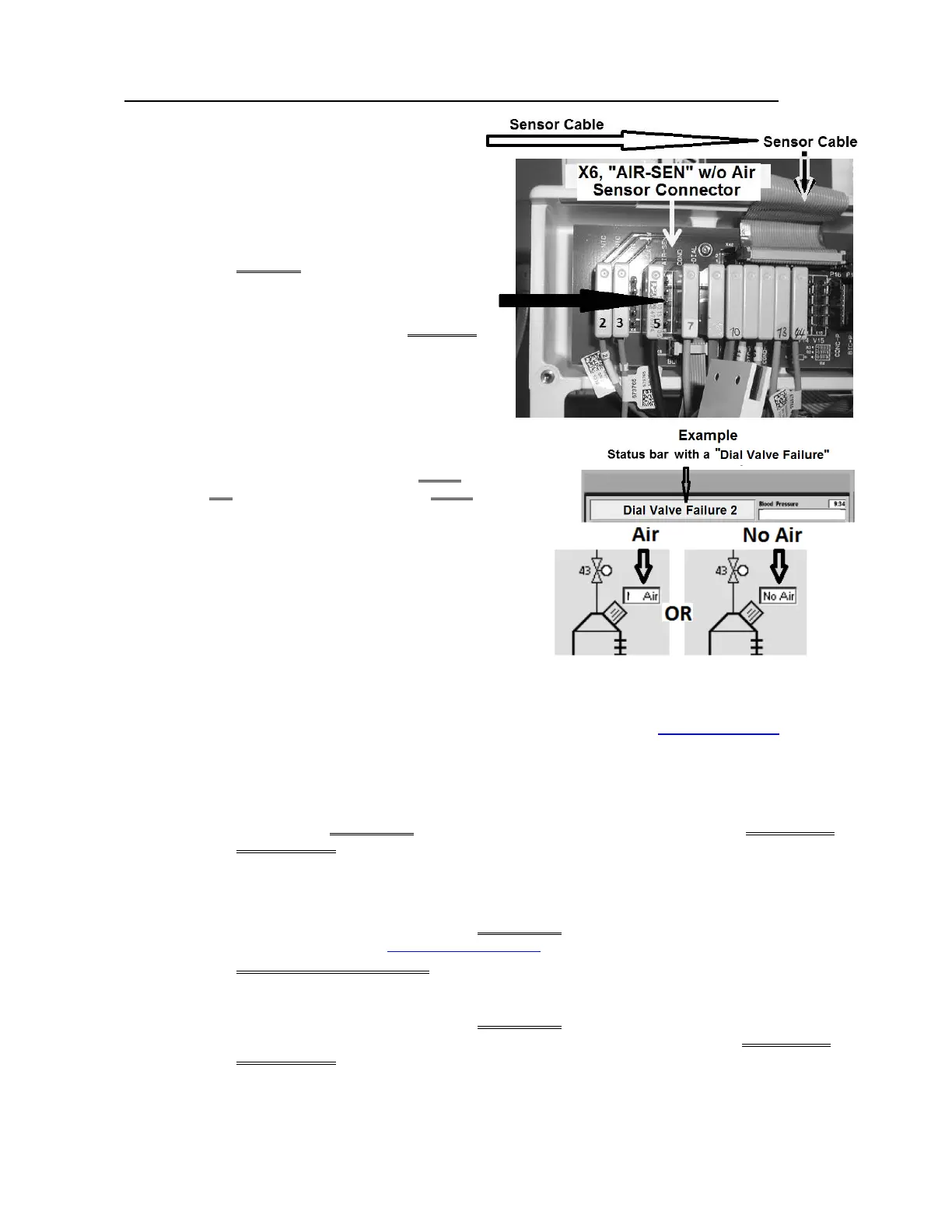

b) Figure right, TWO (2) checks:

Check #1: At the top of the distribution board,

ENSURE the Sensor Cable is

plugged in SECURELY!

Check #2: ENSURE a resistor plug HAS NOT

been prematurely plugged into the

5

th

position from the left!

c) Turn the machine on and return to Dialysis

Program (“Select Program” → ‘Dialysis’ → ‘Enter’)!

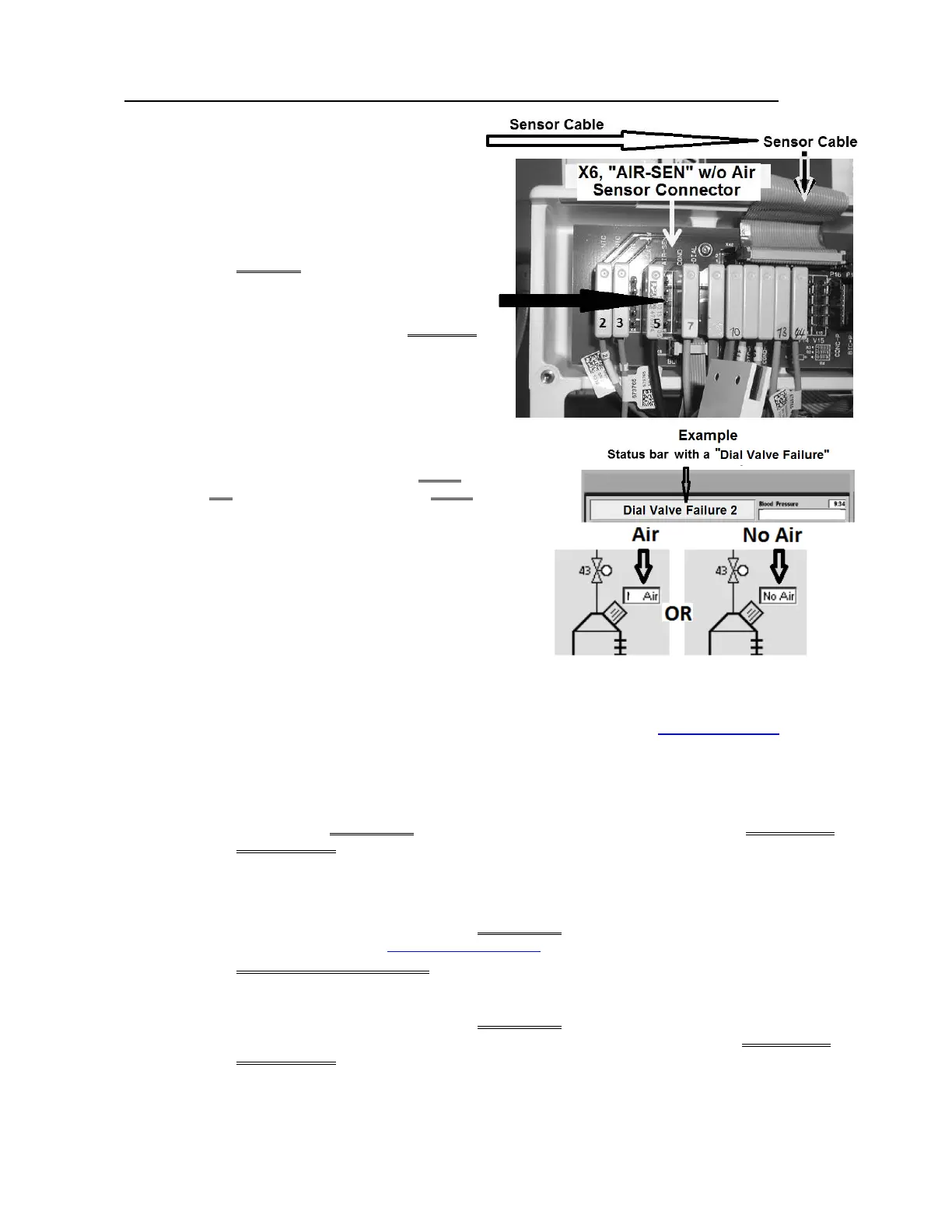

d) Figure right, from here forward, if (and ONLY if) a “Dial Valve

Failure” OR “Act Byp Valve Fail” banner EVER appears

proceed to page 711, Section 26

e) Call debug screen 0. Based on Chamber #69’s

text box now, TWO (2) possible scenarios:

1) IF it says “Air” always: Return to ABOVE

procedure number

F- 1.0.2.11 (page 26).

2) IF it continues to EVER say “No Air”: Filling Program is not working! See parts a AND b below:

a) Before performing part b NOTE this page number THEN perform INITIAL CHECKS (page 7).

b) FIVE (5) possible bad components: 1) CBE board

1

; 2) Sensor Board

2

; 3) Functional Board

3

;

4) Distribution board; 5) Motherboard.

1

A) Swap in a known good CBE board; B) With the Air Sensor’s connector REMAINING

UNPLUGGED return to Dialysis Program (“Select Program” → ‘Dialysis’ → ’Enter’);

C) From debug screen 0, if Chamber #69’s text box now says “Air” the previous CBE board

is bad.

2

A) With the machine off, swap in a known good Sensor Board; B) Place the machine into T

and C Mode (refer to OPERATING MODES (page 19); C) With the Air Sensor’s connector

REMAINING UNPLUGGED, return to Dialysis Program; D) From debug screen 0, if

Chamber #69’s text box now says “Air” the previous Sensor Board is bad.

3

A) With the machine off, swap in a known good Functional Board; B) Pace the new

Functional Board into T and C Mode; C) With the Air Sensor’s connector REMAINING

UNPLUGGED, return to Dialysis Program; D) From debug screen 0, if Chamber #69’s text

box now says “Air” the previous Functional Board is bad.

Loading...

Loading...