2008T Troubleshooting Guide

P/N 490292 Rev. A

SECTION 5 - CONDUCTIVITY / ON LINE CLEARANCE PROBLEMS

External leaks, “No Water” and Flow Errors cause Conductivity problems. If either occur at ANY TIME

address them first! To avoid error observe ALL stated times below!

A) From the Home screen, ENSURE [Dialysate Flow] is on* and has been set to 800 ml/min for five (5)

minutes!

* If [Dialysate Flow] is blinking flow is off! Flow MUST be on!

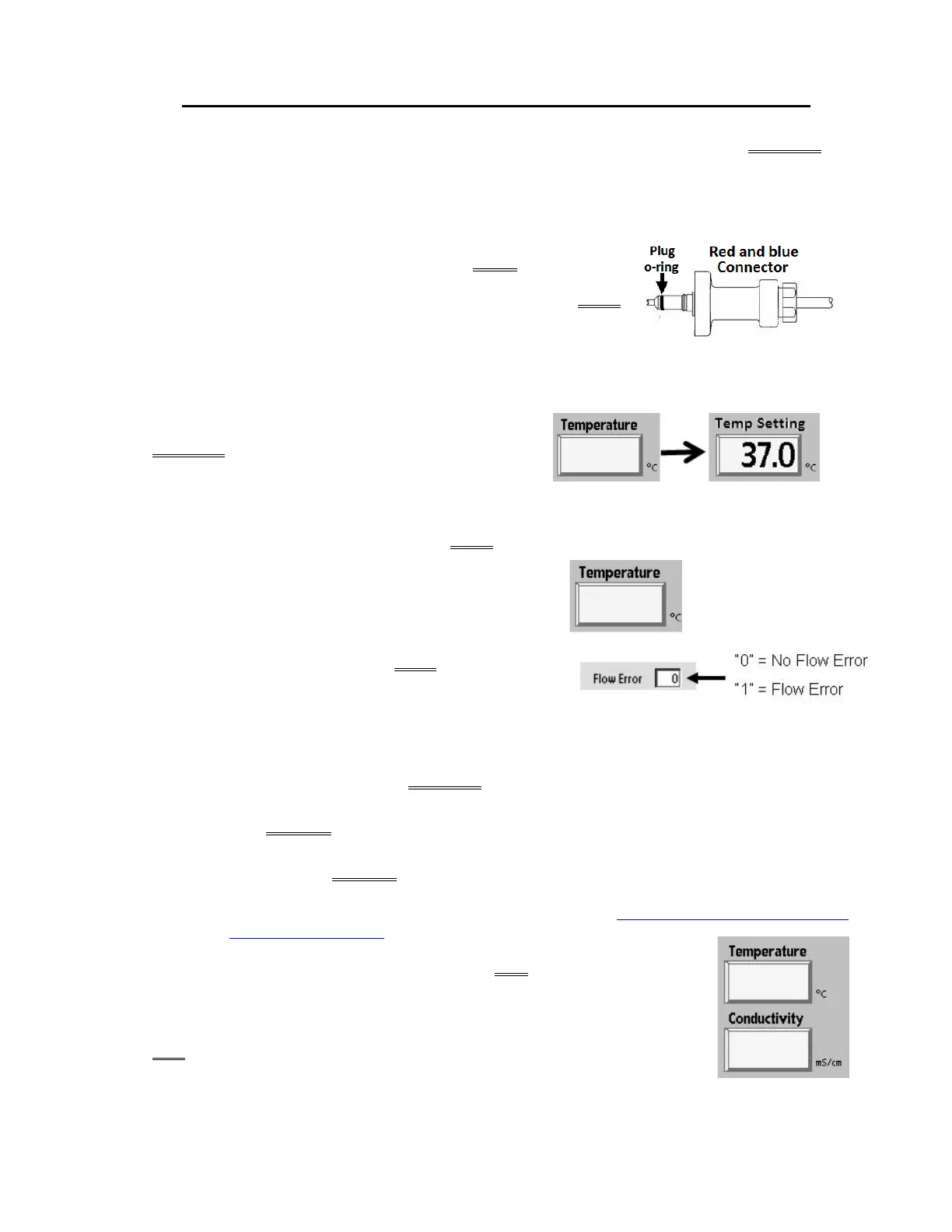

B) If [Conductivity] is less than 12.6 mS, Figure right, ENSURE BOTH

connector plug O-rings are present! If not this may be the problem!

C) If the Automated Tests are running (screen reads “Test:.…”) allow them to finish.

D)

Remove the ‘dummy chamber’ from the Level Detector.

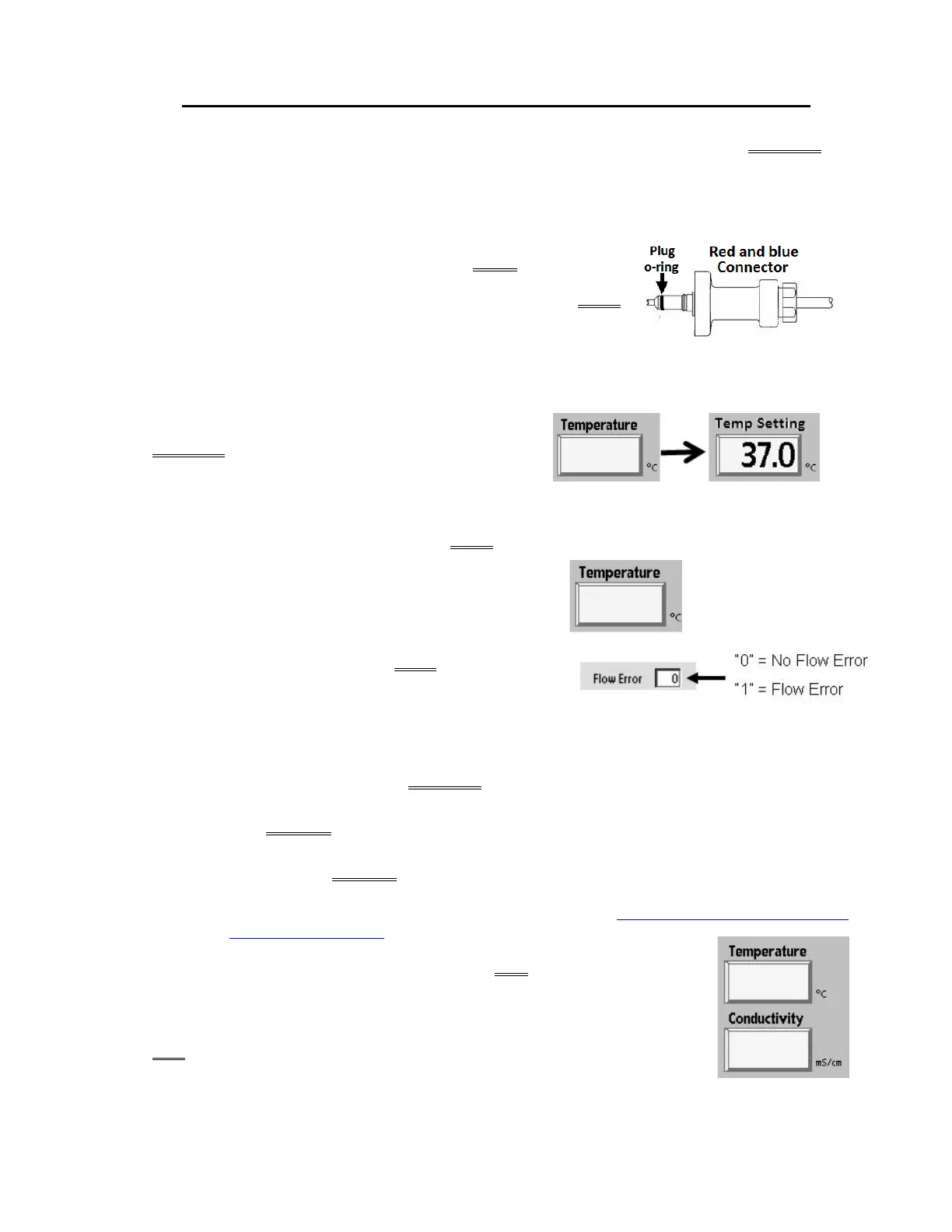

E) Press the [Temperature] window. Is “Temp Setting”

ALREADY = 37.0° C?

Yes “Temp Setting” already = 37.0° C! See part F.

No Adjust “Temp Setting” to 37.0° C THEN continue to part F.

F) Press ‘Enter’ to return to [Temperature].

G)

DO NOT RESET ALARMS!

H) Call debug screen 0. If Flow Error EVER = 1, even just

once, there is a Flow Error! WITHOUT LOOKING AWAY

watch it for, TWO (2) possible scenarios:

Scenario #1: FOUR (4) minutes, if it was necessary to adjust “Temp Setting” to 37.0° C in part E.

Scenario #2: TWO (2) minutes, if it WAS NOT necessary to adjust “Temp Setting” to 37° C in part E.

I) Is Flow Error is ALWAYS = 0?

Yes Flow Error ALWAYS = 0! See part J.

No Flow Error = 1 even if just once! Proceed to page 23, SECTION 1 - FLOW ERRORS IN

DIALYSIS PROGRAM

J) Using a flashlight, ENSURE large air bubbles are NOT moving into the machine

through the acid and bicarb inlet tubing! If air is seen check the connector(s).

K) Call the Home screen. WITHOUT LOOKING AWAY, watch [Temperature]

AND [Conductivity] for one (1) minute. Based first on

[Temperature],

TWO (2) possible scenarios next page:

Loading...

Loading...