2008T Troubleshooting Guide

P/N 490292 Rev. A

Yes ABic = Bic! See procedure number CO- 5.4.0 (page 381).

No ABic is NOT remaining within three (3) of Bic! Watch the Bicarb (BIC)

Pump’s ‘dot’ (Figure right) for TWO (2) minutes. TWO (2) possible

scenarios:

1) IF (and ONLY if) the ‘dot’ EVER turns white: Proceed to

page 409, procedure

number CO- 9.0.0.

2) IF the ‘dot’ REMAINS CONSTANTLY BLUE: Proceed to

page 441, SECTION 6 -

CONCENTRATE PUMP ERRORS.

CO- 5.4.0 ISOLATE ACID PUMP

a) Figure right, ENSURE the Acid (red) AND Bicarbonate

(blue) Connector’s O-rings are present

b) ENSURE the filters is clean AND the adaptor plug is

screwed in tight!

c) Read parts d AND e BEFORE performing them.

d) Perform the ACID (CONCENTRATE) PUMP VOLUME CALIBRATION per the CALIBRATION

PROCEDURES booklet.

e) Can you accurately enter the burette volumes

without an “Operator Error” banner (Figure right)

occurring?

Yes “Operator Error” did NOT occur! See procedure number CO- 5.5.0 (page 381).

No “Operator Error” occurred! Proceed to page 379, procedure number CO- 4.9.0.

CO- 5.5.0 ISOLATE BICARB PUMP

a) Read parts b AND c before performing them.

b) Perform the BICARBONATE PUMP VOLUME CALIBRATION.

c) Can you accurately enter the burette volumes without an “Operator Error” banner occurring (Yes or

No)?

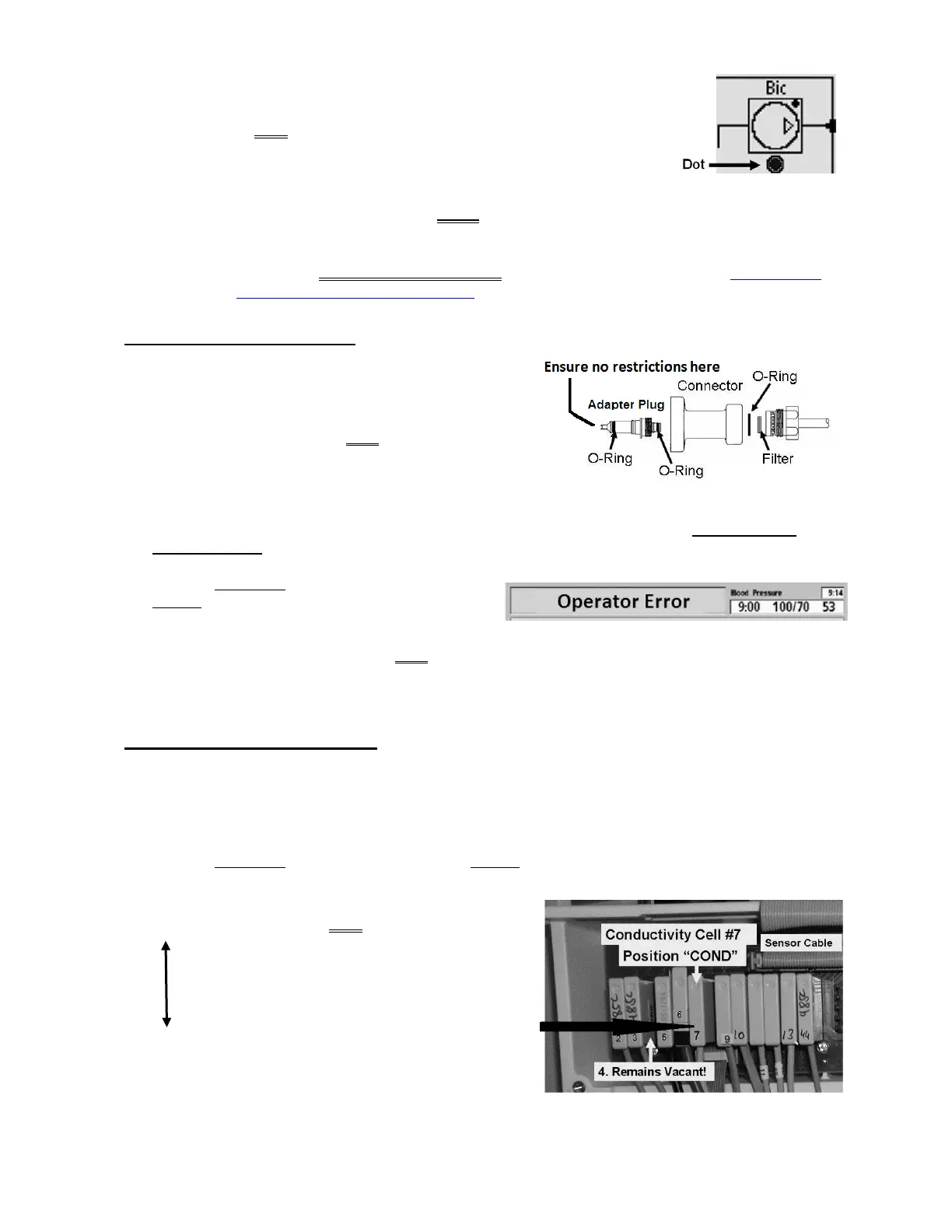

Yes Operator Error” did NOT occur. Per the Figure

right, CAREFULLY trace Cond Cell #7’s wire

harness from distribution board position “X7,

COND” to the cell #7 checking for insulation

damage. If no damage, see procedure number

CO- 5.6.0 (page 382).

No “Operator Error” occurred. Proceed to

page

379, procedure number CO- 4.9.0.

Loading...

Loading...