2008T Troubleshooting Guide

P/N 490292 Rev. A

F- 3.0.0 ISOLATE VALVE #43 (FILLING PROGRAM) DRAIN FLOW

A) WITHOUT returning the Air Sensor’s female connector yet, remove the resistor plug from the distribution

board.

B) ENSURE debug screen 0’s Chamber #69 says “Air”.

C) Obtain a 1000 ml graduated cylinder!

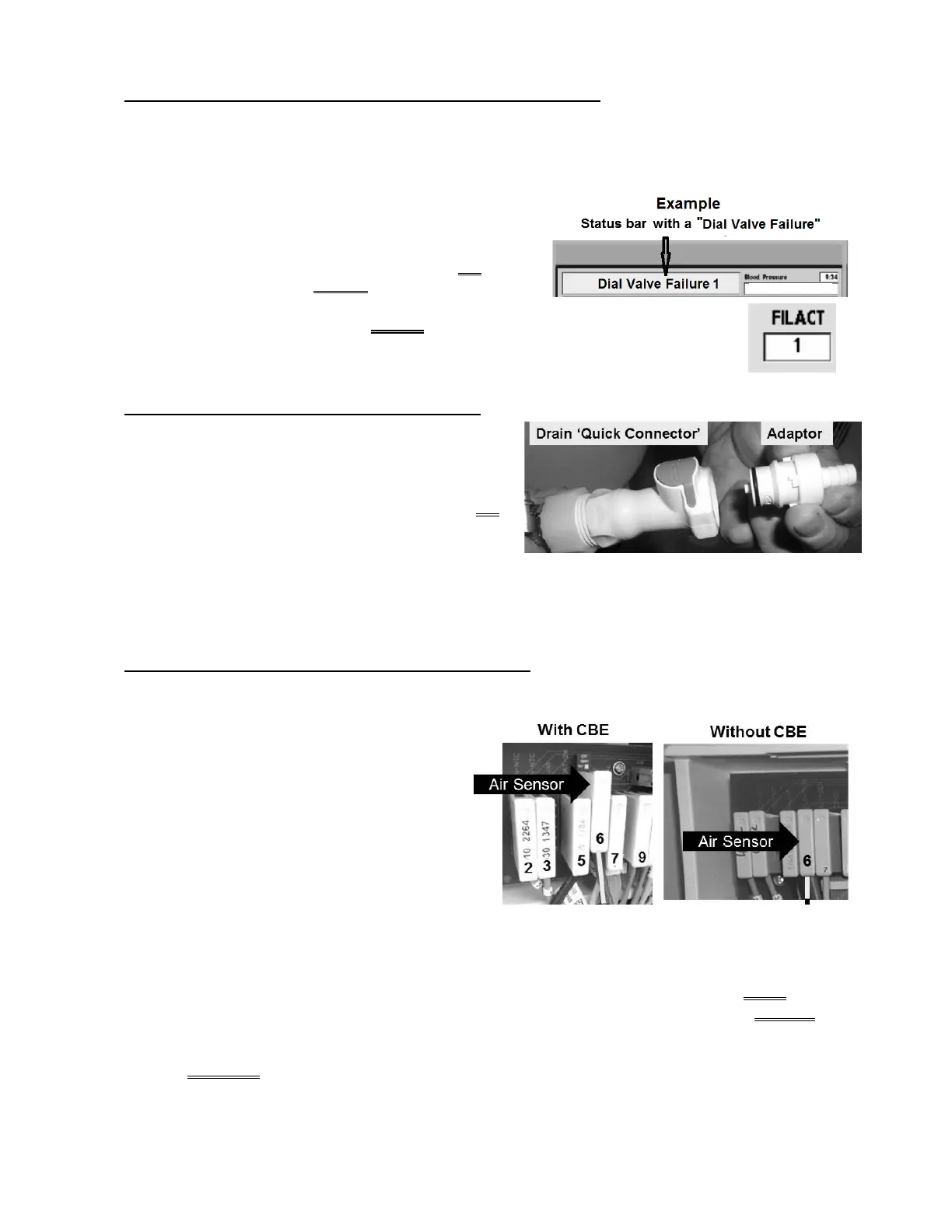

D) Figure right, ENSURE a “Dial Valve Failure” OR “Act

Byp Valve Fail” banner NEVER appears!

E) Call debug screen 1. FILACT MUST ALWAYS = 1 before continuing!

F) See procedure number F- 3.1.0 (page 48).

F- 3.1.0 FILACT = 1 / ISOLATE VALVE #43 FLOW

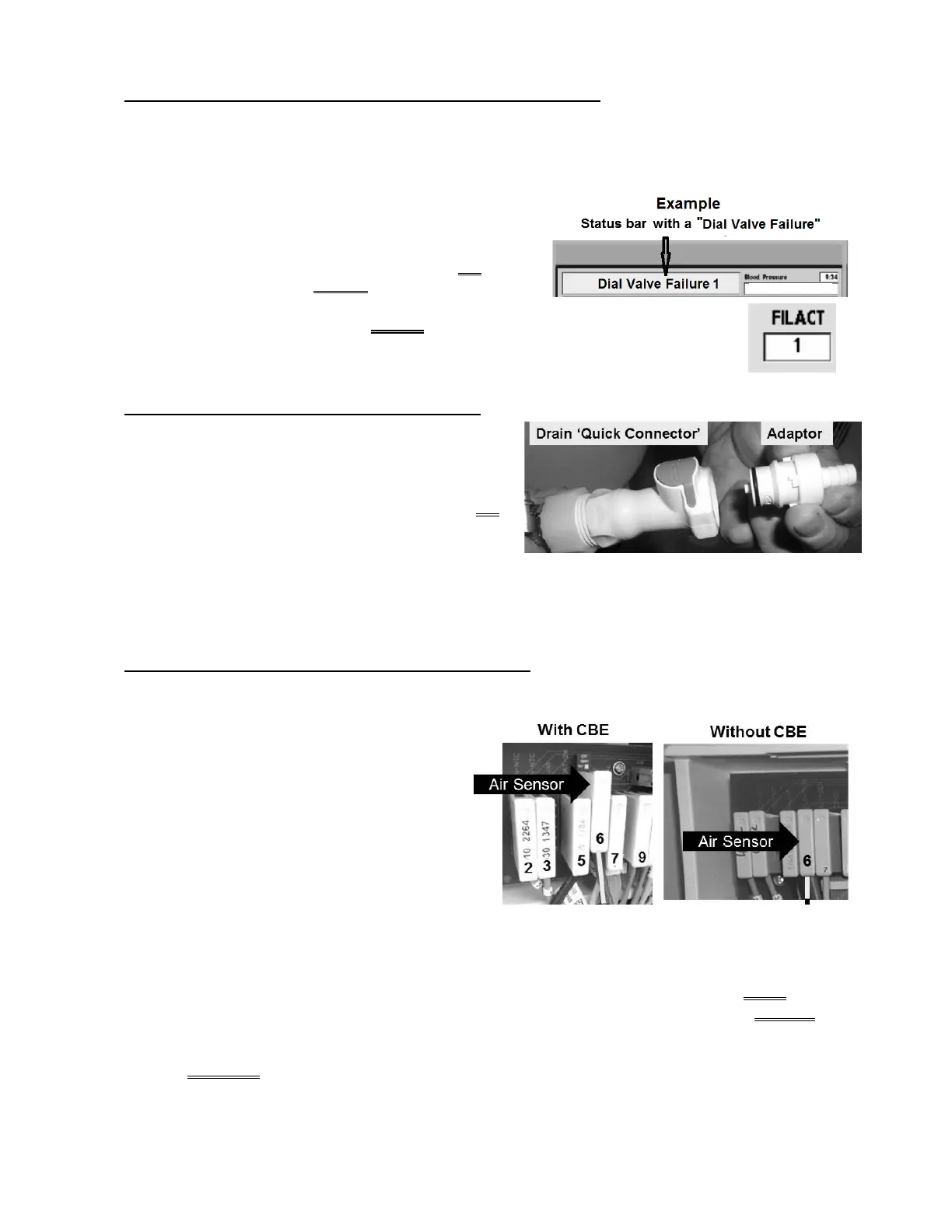

a) Figure right, if a ‘Quick Connector’ is present at the

end of the drain tubing an adaptor is required!

b) Measure drain flow for two (2) minutes. 600 ml OR

more collected?

Yes 600 ml or more! See procedure number F- 3.1.1 (page 48).

No Less than 600 ml! Proceed to

page 49, procedure number F- 3.1.3.

F- 3.1.1 ABOUT 600 ML COLLECTED FROM VALVE #43

a) Reconnect the drain.

b) ENSURE a good drain connection by

listening for or visually veryfying flow!

c) Return the Air Sensor’s female connector to the

5

th

distribution board position from the LEFT.

d) Call debug screen 0.

If the connector is

plugged in PROPERLY Chamber

#69’s text box says “No Air”!

e) In THIS troubleshooting session, did a previous procedure have you ‘swap in’ a DiaSafe

®

filter?

Yes A DiaSafe

®

filter WAS swapped in! Watch Flow Error for five (5) minutes. If it EVER = 1

proceed to page 50, procedure number F- 3.2.0. If Flow Error REMAINS = 0 DO NOT

continue.

No

DO NOT replace the DiaSafe

®

filter at this time! Proceed to page 50, procedure

number F- 3.2.0!

Loading...

Loading...