2008T Troubleshooting Guide

P/N 490292 Rev. A

CLEAN- 1.2.33 LOADING PRESSURE REMAINS LOW

a) Place the machine into RINSE (NOT HEAT DISINFECT)!

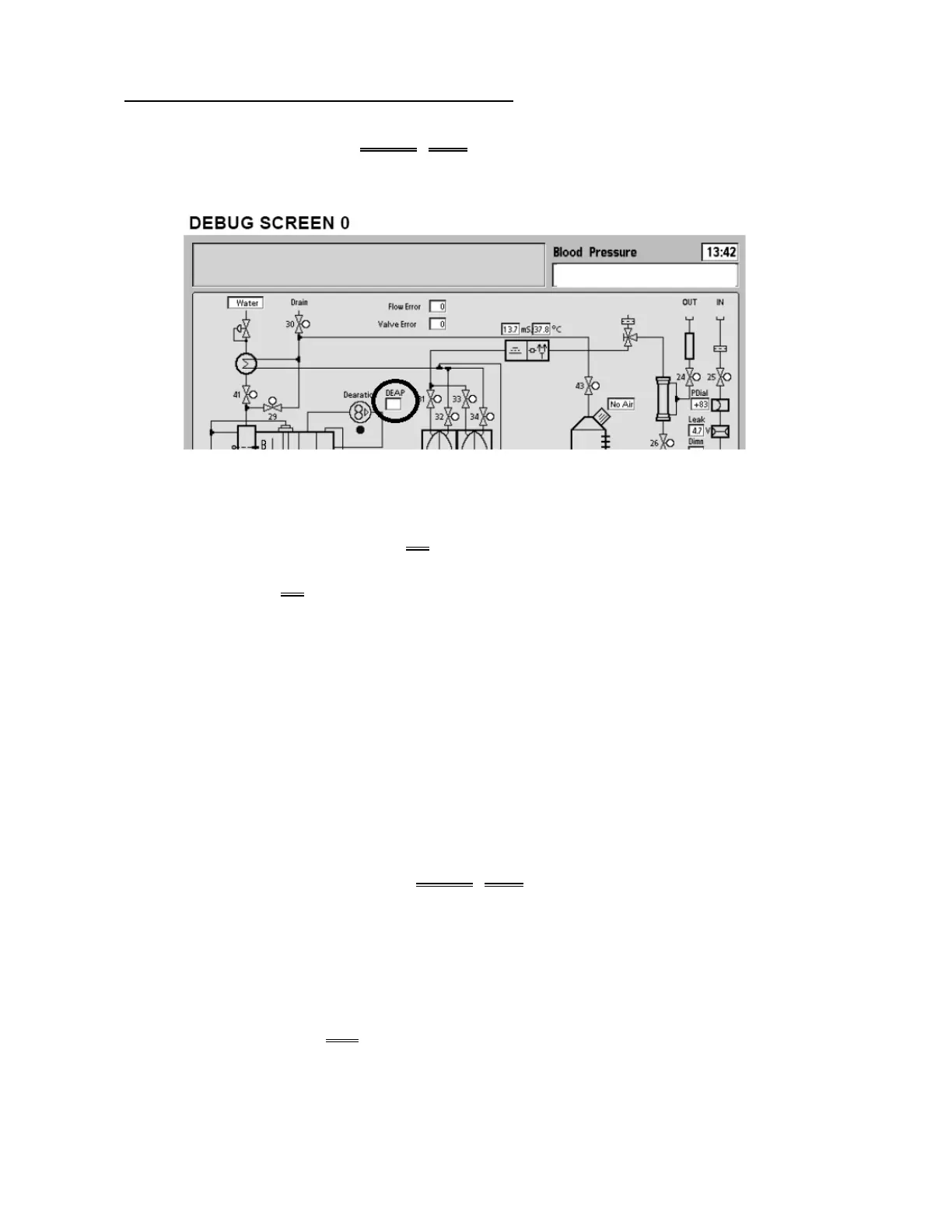

b) Call debug screen 0 (Figure below). If debug does not appear press ‘Esc’ then call screen 0

c) Locate DEAP. TWO (2) possible scenarios:

1) IF (and ONLY if) DEAP = 75 OR less: See procedure number CLEAN- 1.2.4 (page 175).

2) IF DEAP = 76 OR more: See parts a THROUGH i below:

a) Enter Service Mode → Calibrate Hydraulics → Deaeration Pressure. DO NOT follow the

screen instructions! See part b instead!

b) Press ‘Enter’. The screen’s [Pump Rate] window turns yellow.

c) Press the [Pump Rate] window to turn it bright yellow.

d) Set the [Pump Rate] window to “210”.

e)

Press ‘Enter’ twice to save the calibration.

f) Turn the machine off then back on.

g)

Place the machine into RINSE (NOT HEAT DISINFECT).

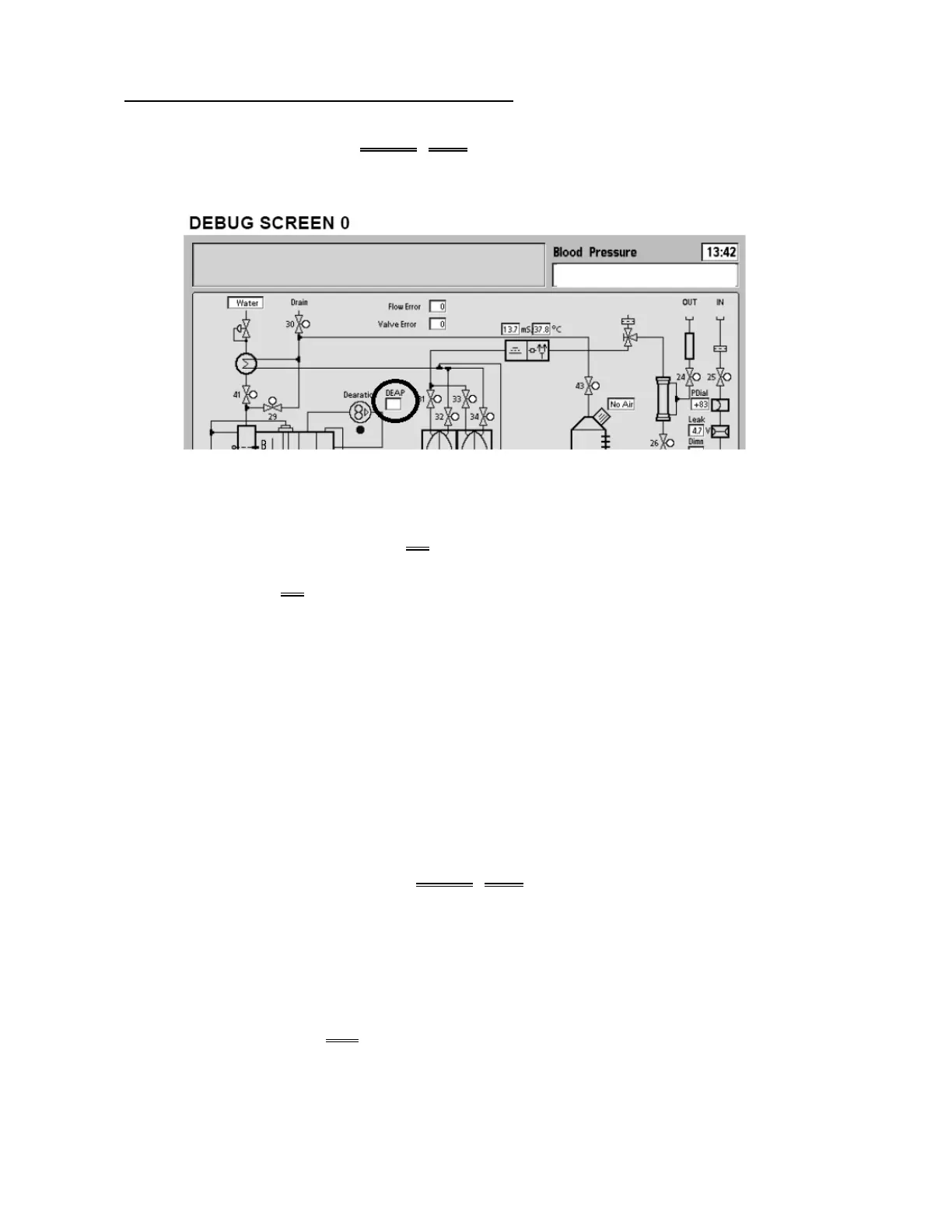

h) Call debug screen 0. If debug does not appear press the ‘Esc’ key then call debug screen 0.

i) Is DEAP now = 45?

Yes DEAP = 45! See procedure number CLEAN- 1.2.4 (page 175).

No DEAP NOT = 45! CAREFULLY repeat the Deaeration Pressure Calibration from part

a). After repeating, if (and ONLY if) DEAP STILL does not = 45, THREE (3) possible

bad components: 1) Bad Actuator-Test Board OR; 2) Bad Functional Board EEPROM

(IC2) OR; 3) Bad Functional Board.

Loading...

Loading...