2008T Troubleshooting Guide

P/N 490292 Rev. A

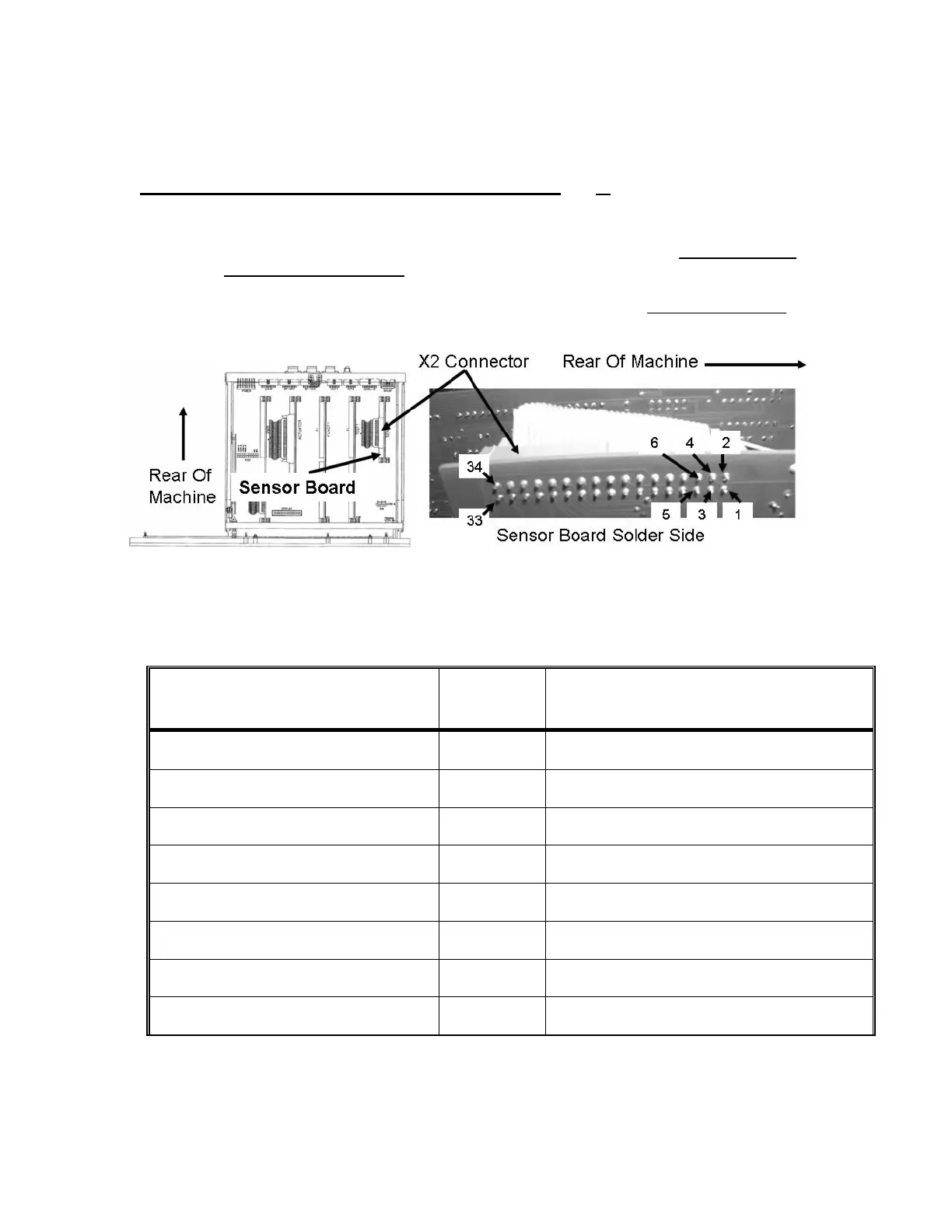

i) Per the Figure below, the cable terminates at the Sensor Board’s X2 connector. The solder (rear) side

PINS are in two rows. Odd numbered in the bottom, even numbered in the top. NOTING the reference

to the ‘Rear of Machine’ locate the appropriate PIN number per Table 14 (page 570

j) Place the second meter on the matching numbered PIN on the solder (rear) side of the P2 connector.

Some components require checking multiple conductors. 2.0

Ω or less for ALL required

conductors?

Yes The cable is good! Return it to the distribution board. If referred to CHECKING THE

SENSOR BOARD CABLE, return to the procedure that brought you here as noted.

No Unplug the cable from the Sensor Board’s X2 connector. Check inside the connector for

damaged male pins. If the pins are okay, replace the cable.

Figure 94 – Electronic Card Cage (Sensor Board)

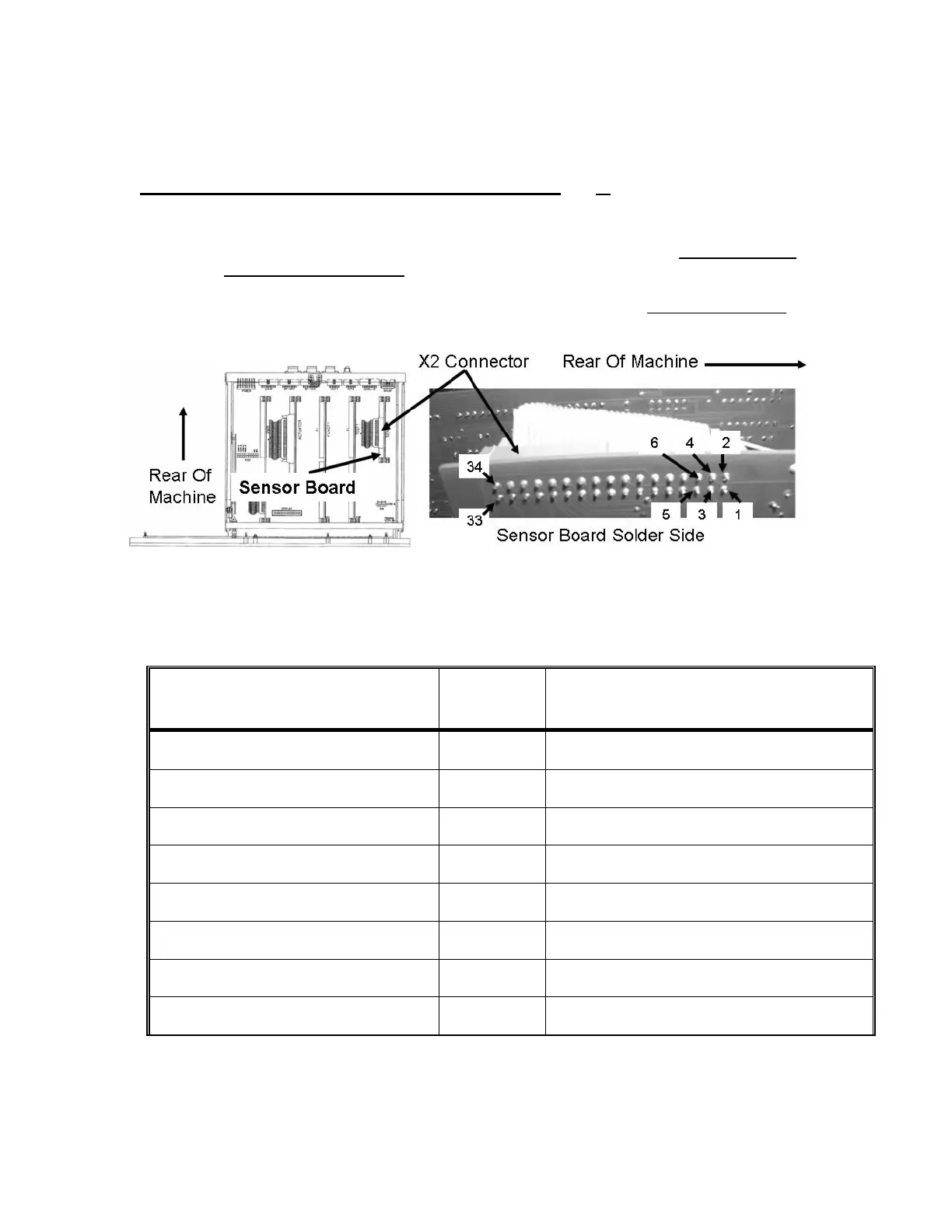

Table 14 – Cable Plug / Sensor Board X2 Pin Locations

Table 14 continued next page

HYDRAULIC COMPONENT

Cable Plug

/ X2 PIN #

Cable Plug / X2 PIN LOCATION

NTC #3 12 Top row, 6 pins from the rear of machine

NTC #2 13 Bottom row, 7 pins from the rear of machine

FLOAT 21 Bottom row, 7 pins from the front of machine

CFS TRANSDUCER (1 of 3) 11 Bottom row, 6 pins from the rear of machine

CFS TRANSDUCER (2 of 3) 14 Top row, 7 pins from the rear of machine

CFS TRANSDUCER (3 of 3) 15 Bottom row, 8 pins from the rear of machine

COND CELL 16 Top row, 8 pins from the rear of machine

ACID EOS 25 Bottom row, 5 pins from the front of machine

Loading...

Loading...