2008T Troubleshooting Guide

P/N 490292 Rev. A

CLEAN- 1.6.0 MACHINE NOT BIBAG

EQUIPPED

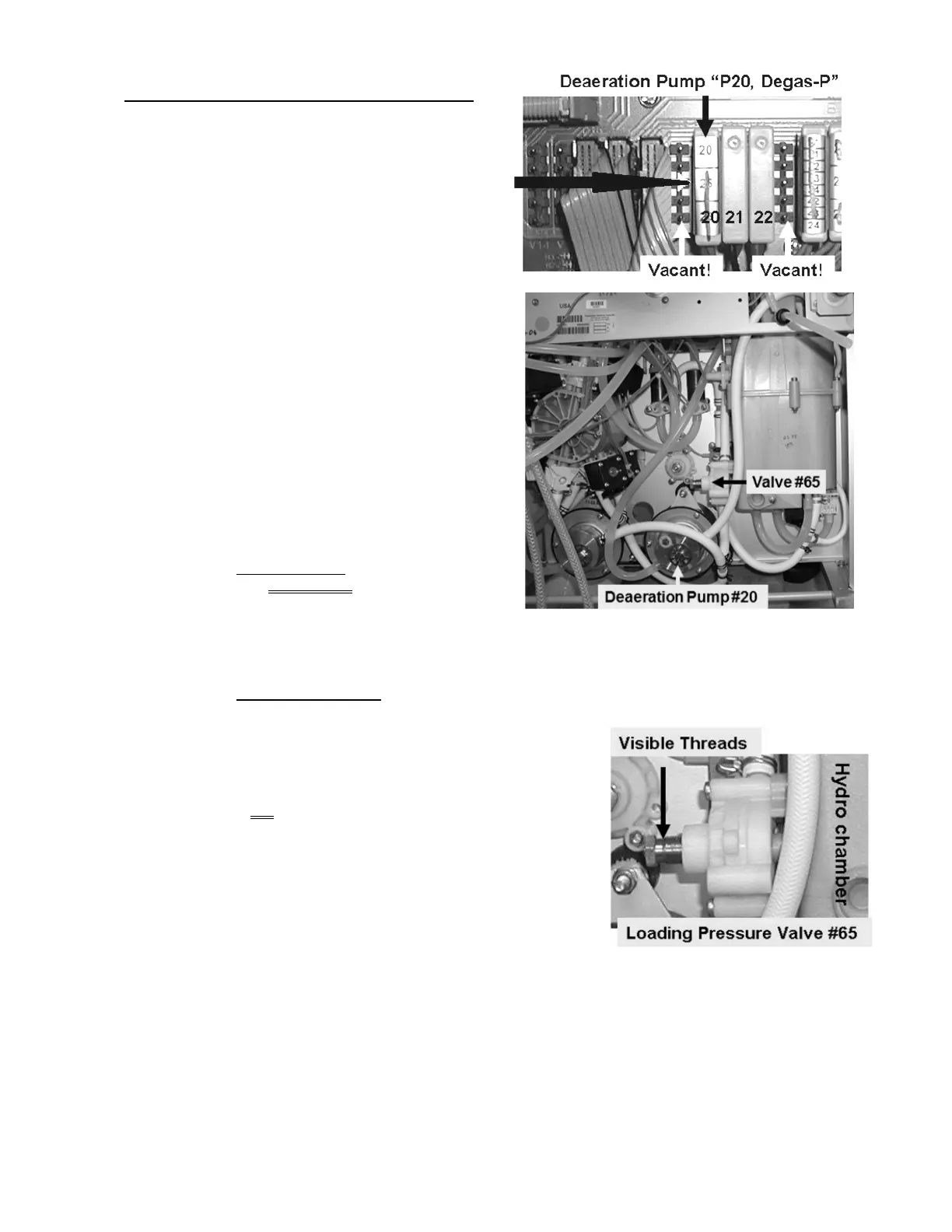

a) Figure right, return the Deaeration Pump to

distribution board position, “P20”!

b)

ENSURE THE DEAERATION MOTOR IS

RUNNING!

c) Figure right, turn Valve #65’s nut clockwise

(tighter) attempting to achieve a PEAK Loading

Pressure of between 23 and 25 psi?

Yes Between 23 and 25 psi! Proceed to

page 189, procedure number

CLEAN- 2.4.0.

No Less than 22 psi! See parts a AND b

below:

a) ENSURE more than 300 ml per minute

input flow to the Deaeration pump i.e.

no recurring air lock!

b) Swap the following components (see

Component List below) one at a time,

with known good then, in between

attemp to adjust Loading Pressure.

When a PEAK pressure of more than 23

psi can be achieved the last component

swapped in is the problem.

COMPONENT LIST: 1) Deaeration Pump head; 2) Deaeration Motor; 3) Valve #65*;

4) Hydrochamber.

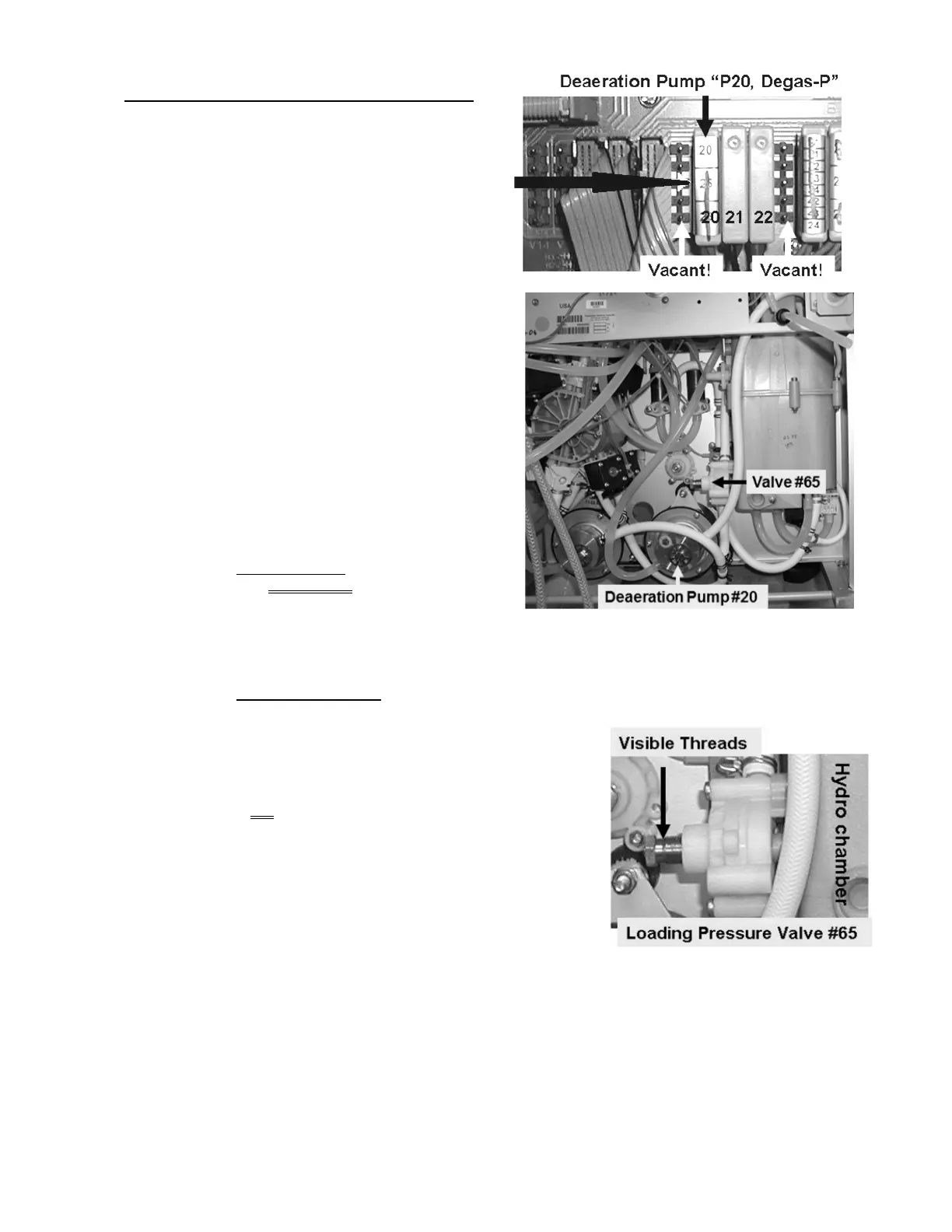

* Figure right, ensure threads are visible under

Valve #65’s nut. If no threads are visible either the

wrong spring is installed** under Valve #65’s nut

OR Valve #65 is bad!

* * Refer to Figure 6 (page 22).

Loading...

Loading...