2008T Troubleshooting Guide

P/N 490292 Rev. A

LEAKING- 1.0.0 UF TUBING BLOWING OFF

a) ENSURE the tubing to and from UF Check Valve #63 is NOT restricted!

b) In the next procedure, but NOT YET, the machine will be placed into RINSE HOWEVER, if a leak occurs

DO NOT turn the machine off but instead, “Interrupt” Rinse by pressing the ‘Esc’ key then ‘Enter’ twice!

c) See procedure number LEAKING- 1.0.2 (page 599).

LEAKING- 1.0.2 ISOLATE RESTRICTION

a) Following there should be:

• No leaks from the Fluid Sample port (Figure right) ONLY if UF Check Valve

#64 is okay!

• ‘Squirts’ into the bucket ONLY if UF Check Valve #63 is okay!

b) Place the acid and bicarbonate connectors into their rinse ports.

c) Turn the machine on

THEN go to RINSE PROGRAM!

d) Allow up to four (4) minutes

OR until if a leak occurs. TWO (2) possible scenarios:

1) IF (and ONLY if) NO leaks! Unless UF Check Valve #63’s tubing ‘blew off’ whatever was causing

the leak is no longer present!

2) IF a leak occurs! With the “Interrupted” banner up perform

parts AND b below:

a) If (and ONLY if) UF Check Valve’s tubing ‘blew off’ it is oriented incorrectly.

b) See procedure number LEAKING- 1.0.4 (page 599).

LEAKING- 1.0.4 LEAK OCCURS

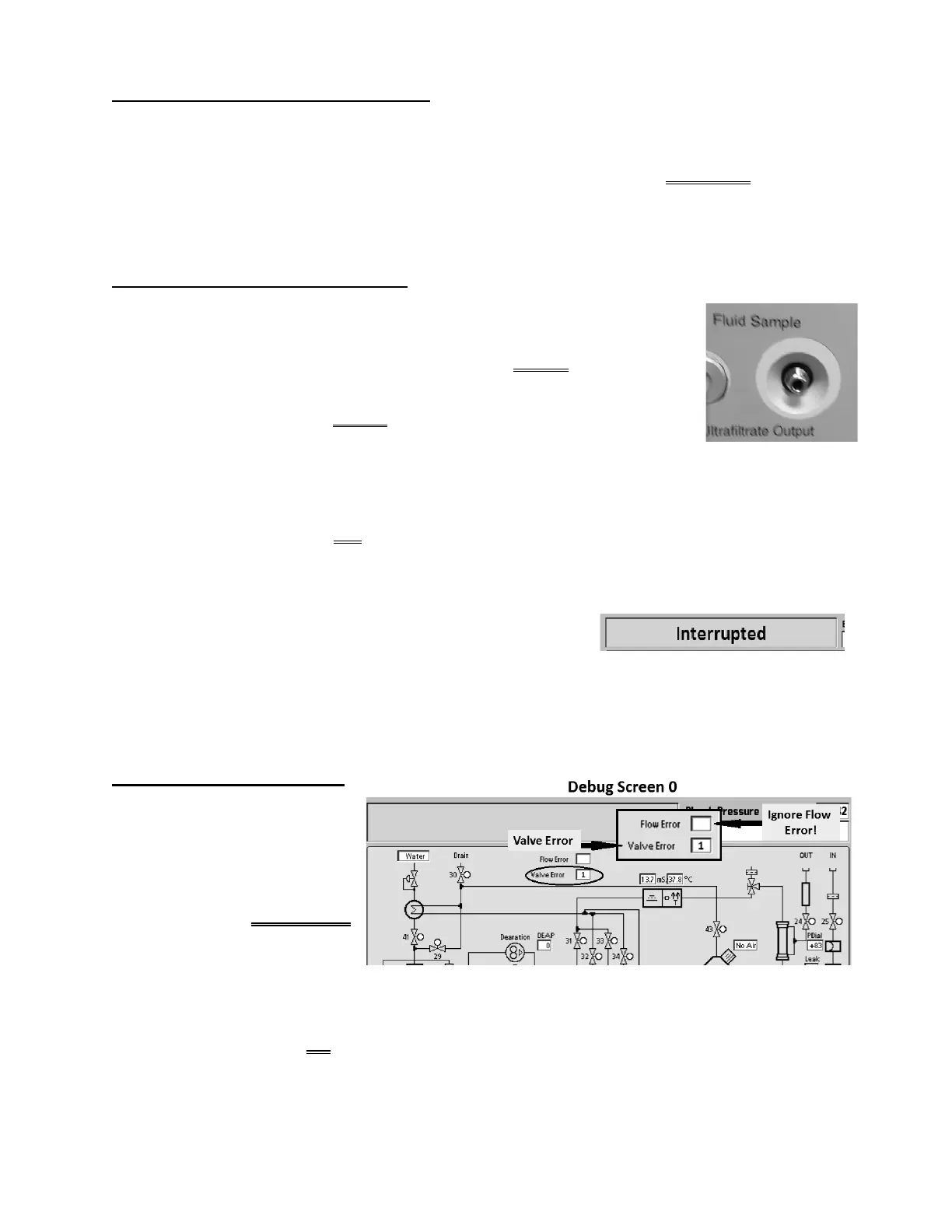

a) Call debug screen 0 (Figure

right). If debug does not appear

press ‘Esc’ then call screen 0.

b) Ignoring Flow Error (TOP

window) look at

Valve Error

the 2

nd

window down!

1) IF (and ONLY if) Valve Error = 1 LONGER THAN two (2) seconds: Proceed to

page 207,

procedure number CLEAN- 7.0.0.

2) IF Valve Error = 0 OR ‘blinks to 1’ for less than one (1) second: Turn the machine OFF then

proceed to page 607, procedure number LEAKING- 4.0.0

Loading...

Loading...