2008T Troubleshooting Guide

P/N 490292 Rev. A

SECTION 19 - TESTING FOR LEAKING BALANCING CHAMBER DIAPHRAGM

A torn balancing chamber diaphragm will cause Flow Errors and/or Temperature and/or Conductivity

problems and/or OLC problems

BC LEAK- 1.0.0 PREPARATION

a) Call debug screen 5. If the debug screens do not appear press the ‘Esc’ key

then call screen 5.

b) IGNORING FPRE for now, is FPOS (Figure right, middle column, BELOW

FPRE) more than nine thousand (9000)?

Yes FPOS more than 9000! See procedure number BC LEAK- 3.0.0 (page 583).

No FPOS is NOT more than 9000. See procedure number BC LEAK- 1.1.0 (page 580).

BC LEAK- 1.1.0 ISOLATE FLOW PUMP (#21)

a) Plug the concentrate connectors into their rinse ports to call the “Select Program” screen.

b) This procedure uses a psi pressure gauge. ENSURE it reads 0 psi before installing it!

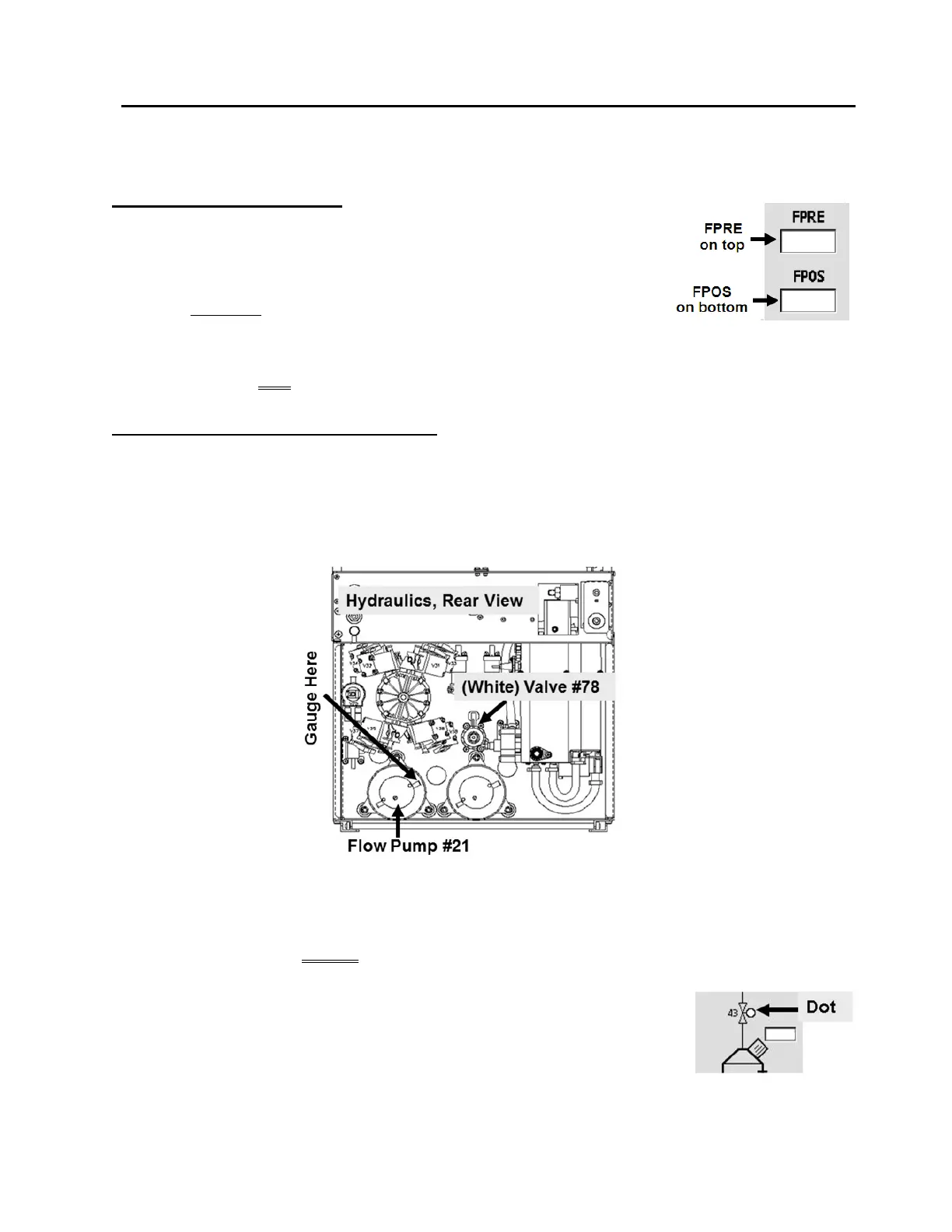

c) Per the Figure below, tee the gauge between the Flow Pump's OUTPUT nozzle and its WHITE tubing.

Figure 97 – Flow Pump Output

d) Tie wrap both sides of the gauge tubing to prevent leaks and false readings!

e) Place the machine into RINSE! Watch for one (1) minute to ENSURE a “No Water” or a Flow Error DO

NOT occur!

f) Call debug screen 0. If debug does not appear press ‘Esc’ then call screen 0.

g) Allow Valve #43’s ‘dot’ (Figure right) to turn blue then WHITE again! While

white, does pressure CYCLE, about every three (3) seconds, to between 35

and 36 psi?

Loading...

Loading...