February 2013

3-53

ColorQube® 9303 Family

IQ 14

Image Quality

IQ 14 Some Colours Uneven RAP

Use this RAP to troubleshoot the following defects:

• Light lines in the process direction

• Dark lines in the process direction

• Light discolouration in wide bands across a whole printhead in the process direction

• Dark discolouration in wide bands across a whole printhead in the process direction

• Discolouration in a single colour primary across the whole page

• Banding in the process direction

Ensure IQ 1 Image Quality Entry RAP is performed before starting this RAP.

Initial Actions

• Enter the customer administration tools, GP 5. On the Tools tab select Troubleshooting

then Automatic Light Lines Fix. Set Quick Fix to On. Set Full Fix to Eco Fix.

NOTE: Ensure that the customer’s Automatic Light Lines and Full Fix settings are

restored to the original settings when the image quality defect has been corrected.

Procedure

WARNING

Ensure that the electricity to the machine is switched off while performing tasks that do

not need electricity. Refer to GP 14. Disconnect the power cord. Electricity can cause

death or injury. Moving parts can cause injury.

CAUTION

Use care when moving the marking unit into the service position when hot. Ink can spill from

the ink reservoir located at the back of the unit if opened with too much force. Cross-colour ink

contamination could also occur.

CAUTION

Do not touch the exposed face of the printheads. Surface contamination or minor damage can

easily make the printhead unusable.

Evaluate the colour bands test page, TP 26. Check for the following defects:

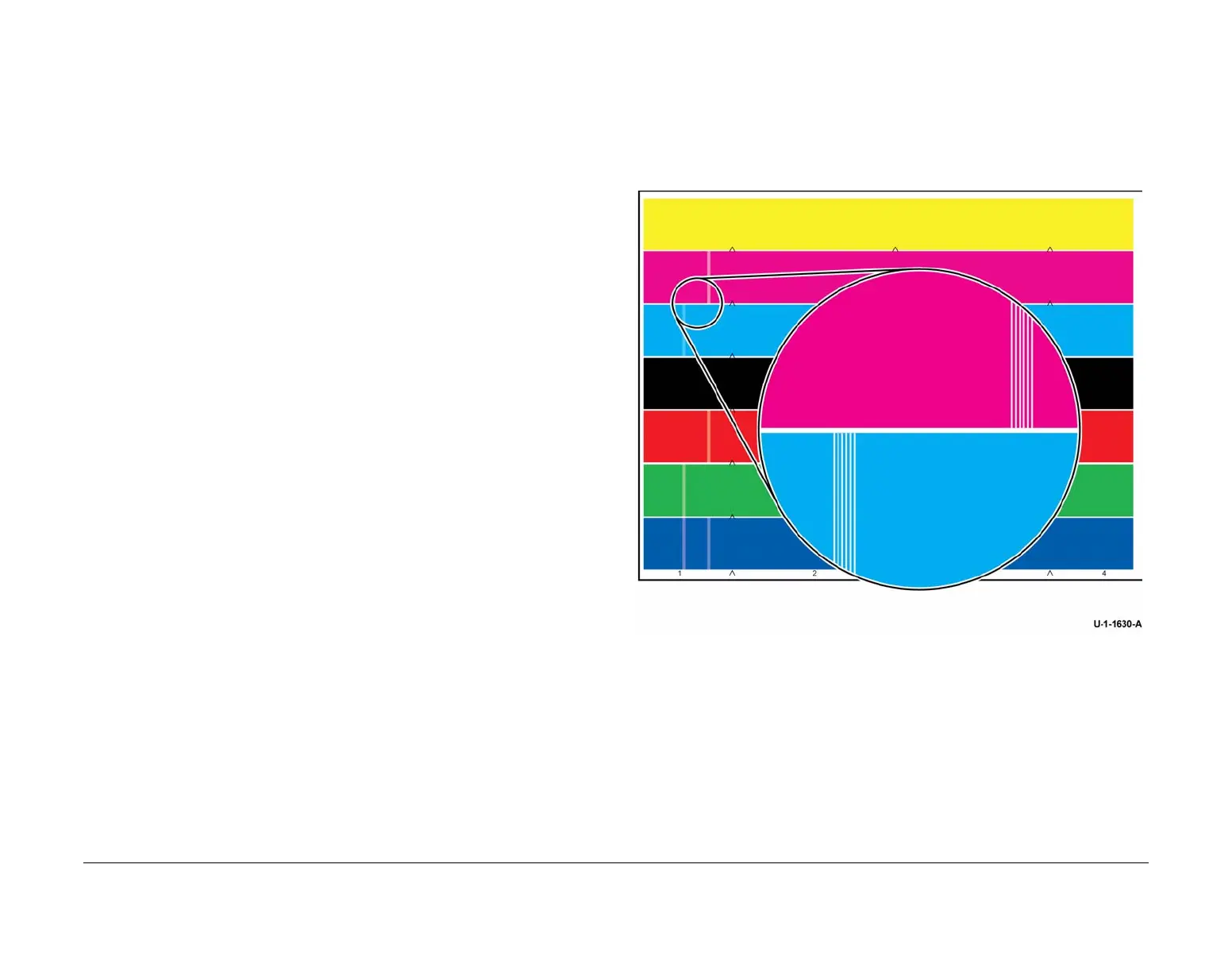

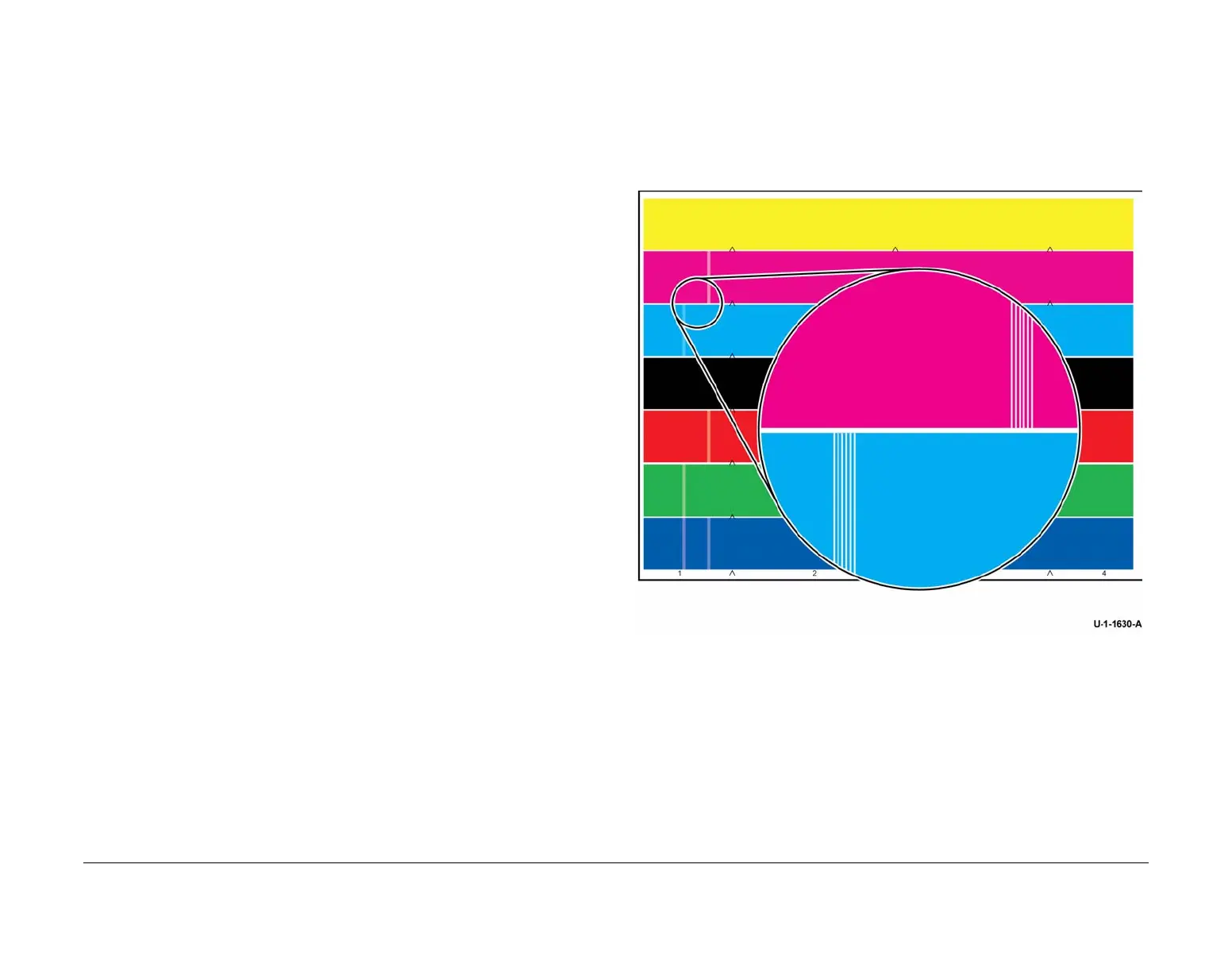

• Light lines in the process direction in a primary colour with corresponding light lines in

secondary colours, Figure 1. Distinct parallel lines, often in groups of six lines, within a

single primary colour and the corresponding secondary colours. If observed, go to the

Missing Jet Checkout.

• Dark lines in the process direction in a primary colour with corresponding dark lines in

secondary colours, Figure 3. Distinct parallel lines, often in groups of six lines, within a

single primary colour and the corresponding secondary colours. If observed, go to the Ink

Mixing at the Printhead Faceplate Checkout.

• Dark discolouration in wide bands across a whole printhead in the process direction, Fig-

ure 4. Uniform dark discolouration across a whole printhead. If observed, go to Ink Mixing

in the Printhead or in the Ink Melt Reservoir Checkout.

• Discolouration across the whole page, Figure 5. Uniform discolouration in a single colour

across the whole page. If observed, go to Ink Mixing in the Printhead or in the Ink Melt

Reservoir Checkout.

• Light discolouration in wide bands across a whole printhead in the process direction, Fig-

ure 5. Uniform light discolouration across a whole printhead. If observed, go to Ink Mixing

in the Printhead or in the Ink Melt Reservoir Checkout.

• Banding in the process direction. Faded bands in the process direction across all colours,

Figure 6 or visible as coloured bands on single colour dithers, Figure 7. If observed, go to

the Banding Checkout.

• If the defect is apparent in all four primary colours, go to the IQ 13 Uneven in All Colours

RAP. If the colours are spatially uniform but incorrect, go to the IQ 15 Wrong Colour RAP.

Figure 1 Missing jet example

Loading...

Loading...