February 2013

4-60

ColorQube® 9303 Family

REP 10.1, REP 10.2

Repairs/Adjustments

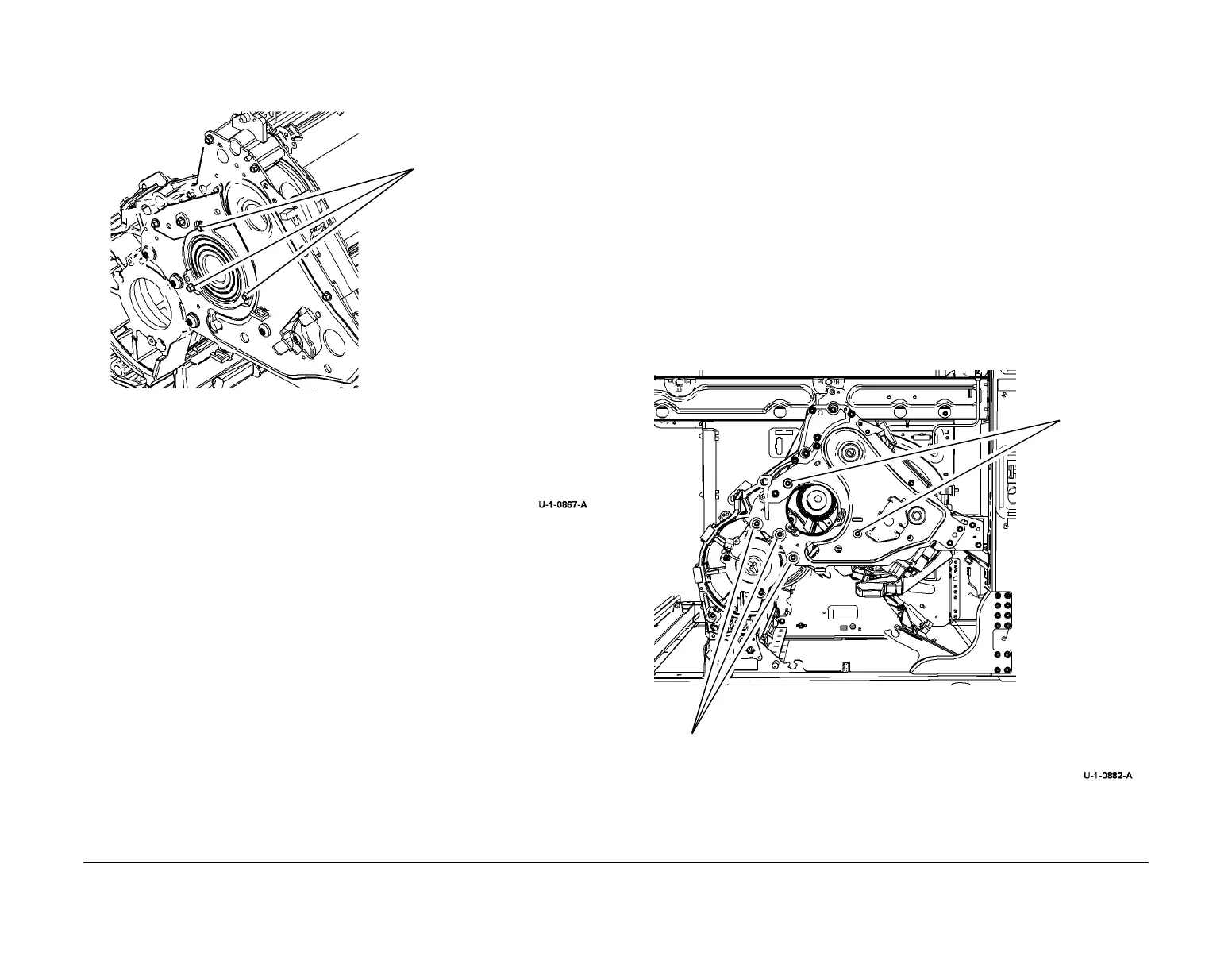

6. Remove transfix roller, Figure 2.

Figure 2 Transfix roll removal

Replacement

1. Replacement is the reverse of the removal procedure.

2. Clean the transfix roller and housing with a dry cloth. Remove all grease that is not neces-

sary.

NOTE: High pressure bearing grease, PL 26.11 Item 3, is used on the outside diameter of

the transfix roller bearing holder. During normal removal and replacement the existing

bearing grease used during manufacture will be sufficient. Only apply grease when both

sides of any bearing surface are being replaced, or if the surfaces have been wiped clean.

Apply the grease very sparingly.

3. Ensure that the ground lead between the top transfix roller screw and the front drum

frame is reconnected.

REP 10.2 Front Transfix Linkage and Gear Kit

Parts List on PL 10.20

Removal

WARNING

Switch off the electricity to the machine. Refer to GP 14. Disconnect the power cord

from the customer supply while performing tasks that do not need electricity. Electricity

can cause death or injury. Moving parts can cause injury.

WARNING

Take care during this procedure. Sharp edges may be present that can cause injury.

CAUTION

Use care when working near the drum. The drum can be damaged easily, which will cause

print quality defects.

1. Remove the transfix roller, REP 10.1.

2. Remove the front drum shroud, PL 94.20 Item 7.

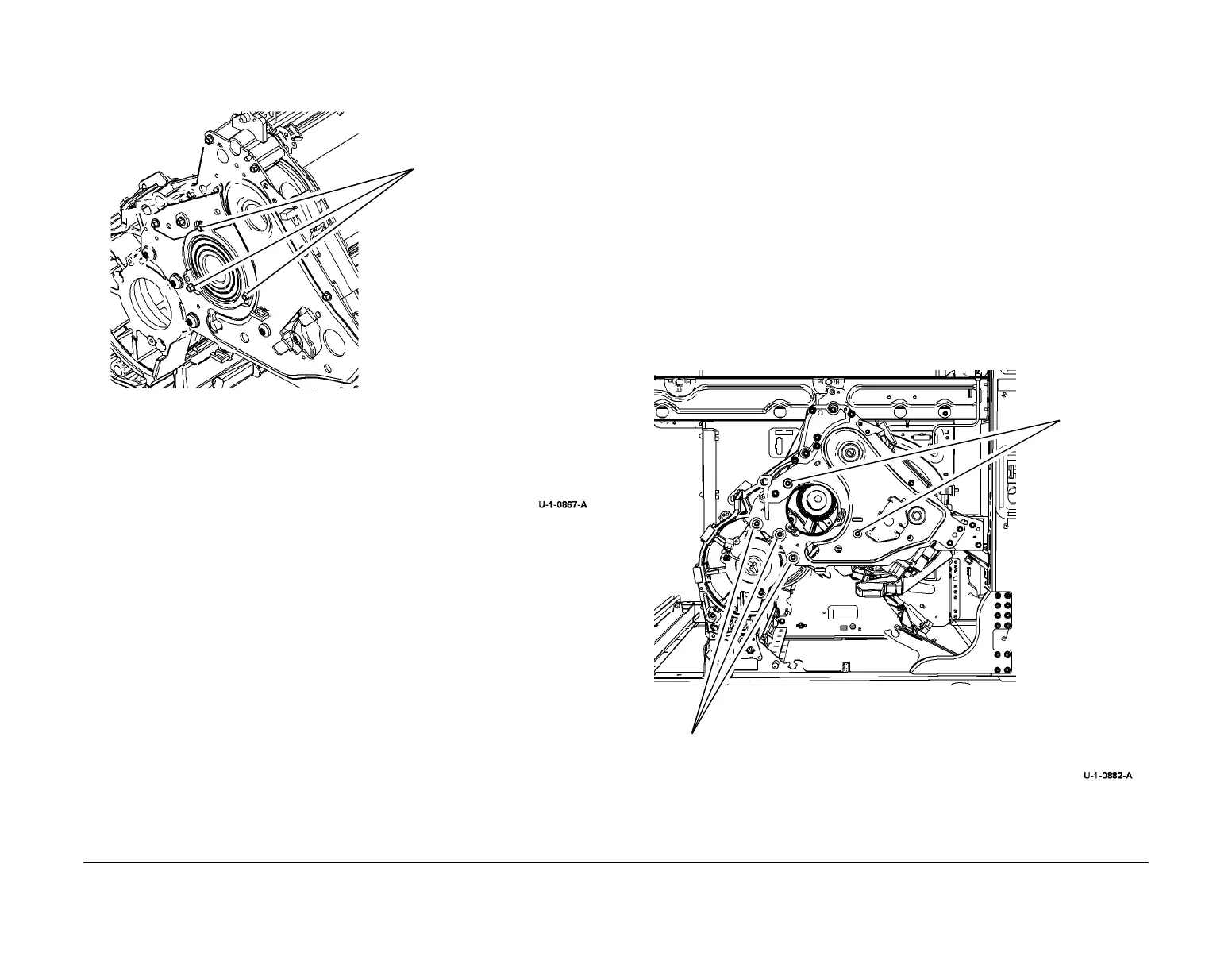

3. Prepare to remove the front plate, Figure 1.

Figure 1 Preparation

2

Install the 3 screws into the

adjacent threaded holes.

Gradually tighten each screw

in sequence to remove the

bearing evenly.

3

Remove the transfix roller

from the front

1

Take note of the cautions

above.

1

Remove 3 T30 screws.

2

Remove 2

long screws

and washers

Loading...

Loading...